Performance in a Compact Form: In-Depth Look at Integrated Diesel Fire Pump Systems

Discover the outstanding advantages of compact integrated diesel fire pump systems, suitable for space-constrained environments, featuring high efficiency, quick installation, and long-lasting fire protection, widely applicable in industrial and commercial settings.

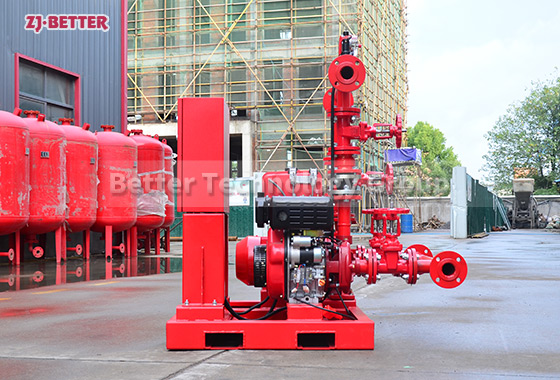

In modern urban buildings and industrial facilities, the spatial utilization and performance of fire safety systems have increasingly become critical considerations in design and procurement. This is particularly true in scenarios where installation space is extremely limited, such as high-density buildings, underground machine rooms, ships, and energy facilities. How to achieve efficient and stable fire pump delivery capacity within a limited area has become a major challenge for the industry. The emergence of compact integrated diesel fire pump systems is precisely aimed at addressing this challenge. It not only integrates all core components such as the diesel engine, water pump, control cabinet, fuel tank, vibration-damping base, and exhaust system but also undergoes in-depth optimization in structural layout and power matching to ensure continuous, reliable, and high-performance firefighting water supply even in extreme space constraints.

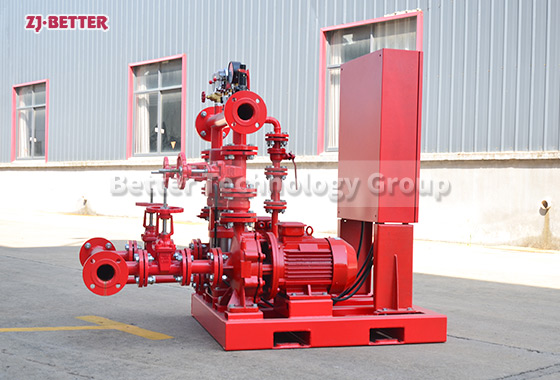

In structural design, the compact integrated diesel fire pump system adopts a modular layout, with all components pre-installed on the same base, significantly reducing installation time and construction intensity. The control cabinet is directly connected to the diesel engine via a cable layout, eliminating complex wiring. Through reasonable thermal insulation and vibration isolation design, the system’s overall stability is effectively enhanced. In limited spaces, all maintenance access points are externally accessible, facilitating post-installation maintenance and operational monitoring. Additionally, the system features intelligent start/stop logic, enabling automatic operation based on system pressure or control signals, truly achieving unmanned operation.

In terms of performance, the system is equipped with high-efficiency diesel-driven units, offering high torque output and exceptional durability, ensuring rapid startup and continuous operation even under extreme high-temperature or humid conditions. The pump section utilizes a high-pressure, high-flow model compliant with NFPA 20 standards, combined with an optimized hydraulic design to enhance overall efficiency and reduce energy consumption. The fuel tank is typically configured as an internal large-capacity structure, minimizing the need for external equipment while extending the runtime per refueling. The cooling system supports both air-cooled and water-cooled configurations to accommodate diverse regional and operational requirements.

In terms of safety and intelligence, this type of fire pump system is generally equipped with multiple protection mechanisms and remote monitoring functions. Multiple operational parameters, including oil temperature, water temperature, oil pressure, speed, and exhaust temperature, can be monitored in real-time and trigger alarms. In case of abnormalities, the system automatically shuts down for protection. It also features three control modes: manual, automatic, and remote, and supports multiple communication protocols, facilitating integration with building fire control centers. Furthermore, the electrical control system uses an IP55-rated enclosure, effectively resisting dust and moisture intrusion to ensure stable outdoor operation over the long term.

In practical applications, compact integrated diesel fire pump systems are widely used in municipal buildings, large commercial complexes, subway stations, tunnel projects, energy and chemical plants, port warehouses, oil platforms, and high-risk industrial areas. Due to its integrated structure, ease of transportation, and plug-and-play functionality, it is particularly suitable for projects with tight schedules, stringent installation conditions, limited space, but strict fire safety requirements. Customization options include varying flow rates, head, diesel engine power, and control logic to perfectly align with the performance parameters and safety standards of each fire protection system.

Additionally, the system undergoes comprehensive simulated testing before shipment, including no-load, loaded, automatic start-up, alarm, and switching tests, ensuring it is ready for operation upon delivery and avoiding post-construction commissioning challenges. Its high degree of standardization and modularization facilitates large-scale deployment and after-sales maintenance. Furthermore, to meet the regulatory requirements of different countries and regions, optional features such as UL/FM-certified pump sets, environmentally friendly soundproof enclosures, explosion-proof control cabinets, and anti-freeze heating modules can be selected, further expanding its international application adaptability and competitiveness.

In summary, the compact integrated diesel fire pump system, with its outstanding structural integration capabilities, stable and efficient power output, intelligent and reliable control system, and wide adaptability, is the ideal choice for current and future building fire protection applications. It not only reflects the integration trend in modern fire protection equipment technology but also demonstrates significant advantages in terms of space-saving installation, simplified construction processes, and enhanced operational efficiency through optimized design. For projects seeking high reliability and space utilization, it is undoubtedly a forward-thinking and practical solution.