Secure Operation Through Redundancy: Performance Analysis of Dual-Drive Emergency Fire Pump Stations

Explore the outstanding performance and reliability of dual-power emergency fire pump stations. The system is specially designed for harsh environments and uses dual redundancy with diesel and electricity to ensure continuous operation of the firefighting system. It is suitable for critical infrastructure and industrial safety applications.

In modern buildings and industrial facilities, fire safety systems have evolved from basic sprinkler systems and alarm devices into complex and highly demanding protection systems. Within this system, the fire pump station serves as the “heart” of the system, and its performance and reliability directly impact the building’s response efficiency in the event of a fire. Especially in high-security environments such as chemical industrial parks, power substations, large commercial centers, and high-rise buildings, single-drive pump stations can no longer meet the multiple demands for redundancy, safety, and continuous operation. Therefore, the emergence of dual-power emergency fire pump stations represents a groundbreaking technological innovation.

The design philosophy of dual-power fire pump stations is based on the principle that “the system should not cease operation due to a single point of failure.” It integrates diesel-driven and electric-driven modes, forming a highly reliable structure where the two systems serve as mutual backups and automatically switch between each other. When the primary power system fails, power is interrupted, a sudden fire occurs, or there are severe fluctuations in the grid power supply, the backup drive immediately takes over to ensure continuous operation of the pump station. This redundancy mechanism significantly enhances the system’s availability during critical moments, providing an additional layer of safety for buildings.

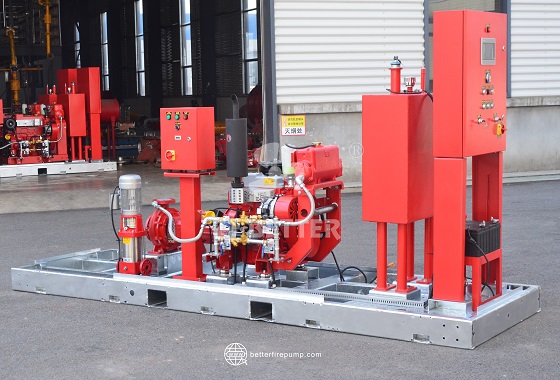

In terms of equipment construction, the dual-drive pump station integrates a high-performance diesel engine, a three-phase electric motor, a highly efficient end-suction or single-stage centrifugal pump body, an intelligent control system, an automatic switching logic module, a fuel supply system, a cooling system, a vibration-damping base, and independent alarm and data feedback interfaces. The system has a compact structure and a small footprint, making it suitable for equipment rooms with limited installation space; it also has all-weather operational capabilities, adapting to different climatic environments and operational conditions.

Its control logic is particularly advanced, utilizing a PLC programmable controller for multi-state monitoring and logical judgment, enabling functions such as switching to diesel drive upon power failure, automatically initiating a preheating program, system pressure differential alarms, and pressure sensor malfunction alarms. It also features a color touchscreen human-machine interface, allowing users to monitor real-time system status, historical operation records, and current alarm information.

From a safety perspective, the dual-power fire pump station possesses exceptional risk-resistance capabilities. In the event of natural disasters or human-caused disruptions leading to main power outages, the diesel-powered system immediately serves as the first line of defense, ensuring the entire pump station can be operational within the shortest possible time to secure valuable rescue time. Conversely, when diesel fuel cannot be replenished in time or mechanical issues arise, the electric drive system can operate independently to meet emergency water supply needs. This bidirectional fault-tolerant redundant system provides stable and reliable emergency support for high-risk environments.

Energy efficiency and environmental sustainability are also key design considerations. The electric drive system operates at low energy consumption during routine tests and non-emergency situations, effectively reducing operational costs. The diesel system is equipped with high-efficiency fuel injectors and optimized combustion structures, achieving lower carbon emissions and higher fuel utilization rates. Additionally, noise control, cooling system layout, and exhaust treatment solutions have been optimized to comply with environmental regulations in multiple countries.

In terms of maintenance, the system design emphasizes modularity, visualization, and predictive maintenance. Each functional unit uses quick-connect fittings and easy-disassembly structures for convenient replacement and repair. The control system supports remote diagnostics and mobile synchronization, enabling operators to remotely view alarm information and operational records, as well as perform parameter settings and fault predictions, thereby enhancing maintenance efficiency.

The dual-drive fire pump station also supports multiple communication protocols, enabling seamless integration into Building Automation Systems (BAS), intelligent fire platforms, or industrial IoT frameworks. This facilitates smart interlocking control, data upload, and multi-level alarm linkage. It also features an RS485 interface and 4-20mA analog output, making it compatible with various automated monitoring platforms.

Depending on customer requirements, the system can be configured with weatherproof, containerized, or noise-reduction enclosures, suitable for outdoor or harsh environment installations. It also supports customized drive power ranging from 37kW to 315kW, accommodating pump configurations with varying scales and head requirements, meeting fire protection needs from medium-sized commercial buildings to large-scale industrial projects.

In summary, the dual-power emergency fire pump station achieves a perfect combination of safety, stability, and sustainability through its diesel and electric drive redundant design. Its highly intelligent, modular, energy-efficient, environmentally friendly, and remotely controllable advantages are increasingly becoming the preferred choice for high-end fire protection systems worldwide. In the future, with the advancement of smart city construction and Industry 4.0, this highly reliable and adaptable fire protection equipment will play an irreplaceable key role in more fields.