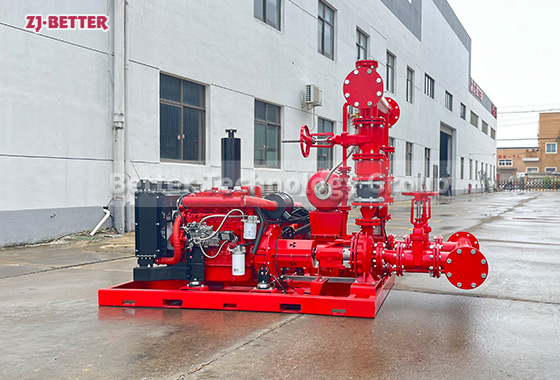

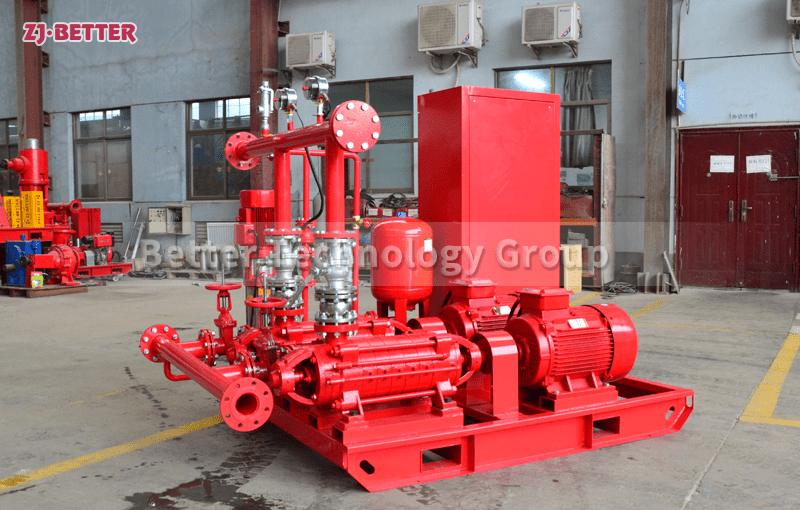

Five small fire pump sets with a small footprint

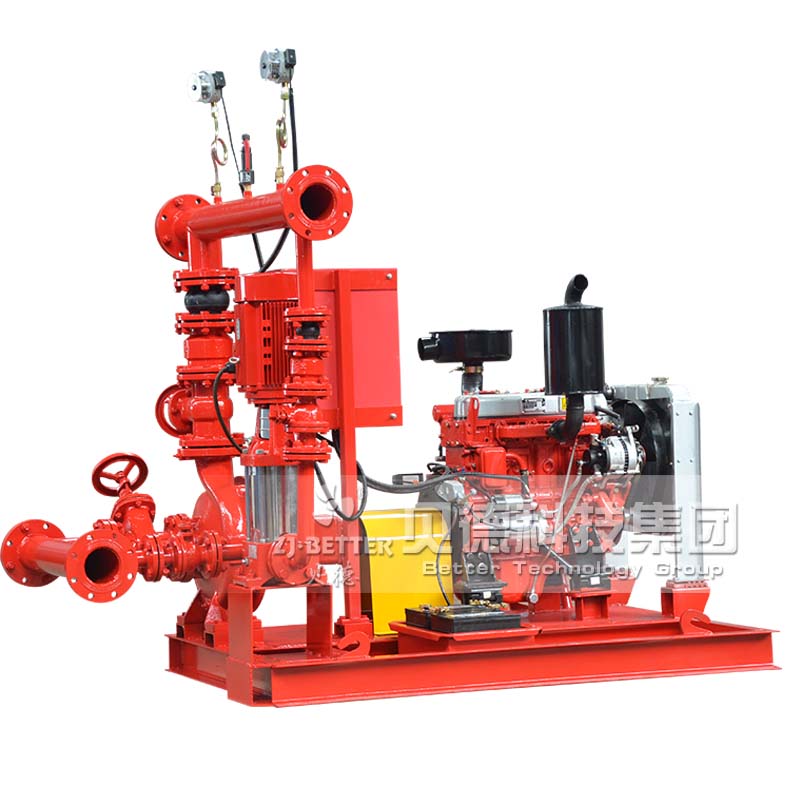

The diesel engine fire pump is usually used as a backup facility, so it will only start automatically when the fire signal comes, and when the electric water pump fails or the power supply is cut off. When it has a device for starting the pump at ultra-low pressure, its matching electric water pump control cabinet should also have a device for starting the pump at ultra-low pressure, and the lower limit of the two pumps should have a certain pressure difference.

Diesel engine fire pump is a good water supply equipment, which is widely used in both ordinary water supply and fire water supply. As long as you choose the appropriate model to match the application, and do a good job of inspection and maintenance, the diesel engine fire pump will basically not fail. Diesel engine fire pumps are highly automated, and can be equipped with different operating systems according to the needs of use. They have strong overload capacity, convenient maintenance, and good start-up characteristics. Since there are so many advantages in use, the daily inspection and maintenance work should be more meticulous. The daily maintenance of the diesel engine fire pump must check the fuel tank, battery, transmission connection plate, connecting screws, check the three leaks (water, oil, gas) – check the sealing surface of the oil pipe and water pipe joint, etc.