Vertical In-Line Fire Pump System Solutions for Space-Limited Fire Protection Projects

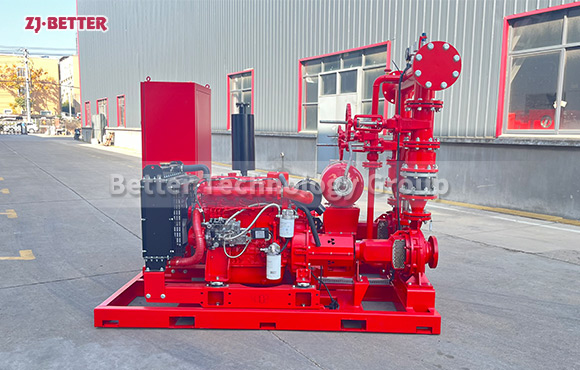

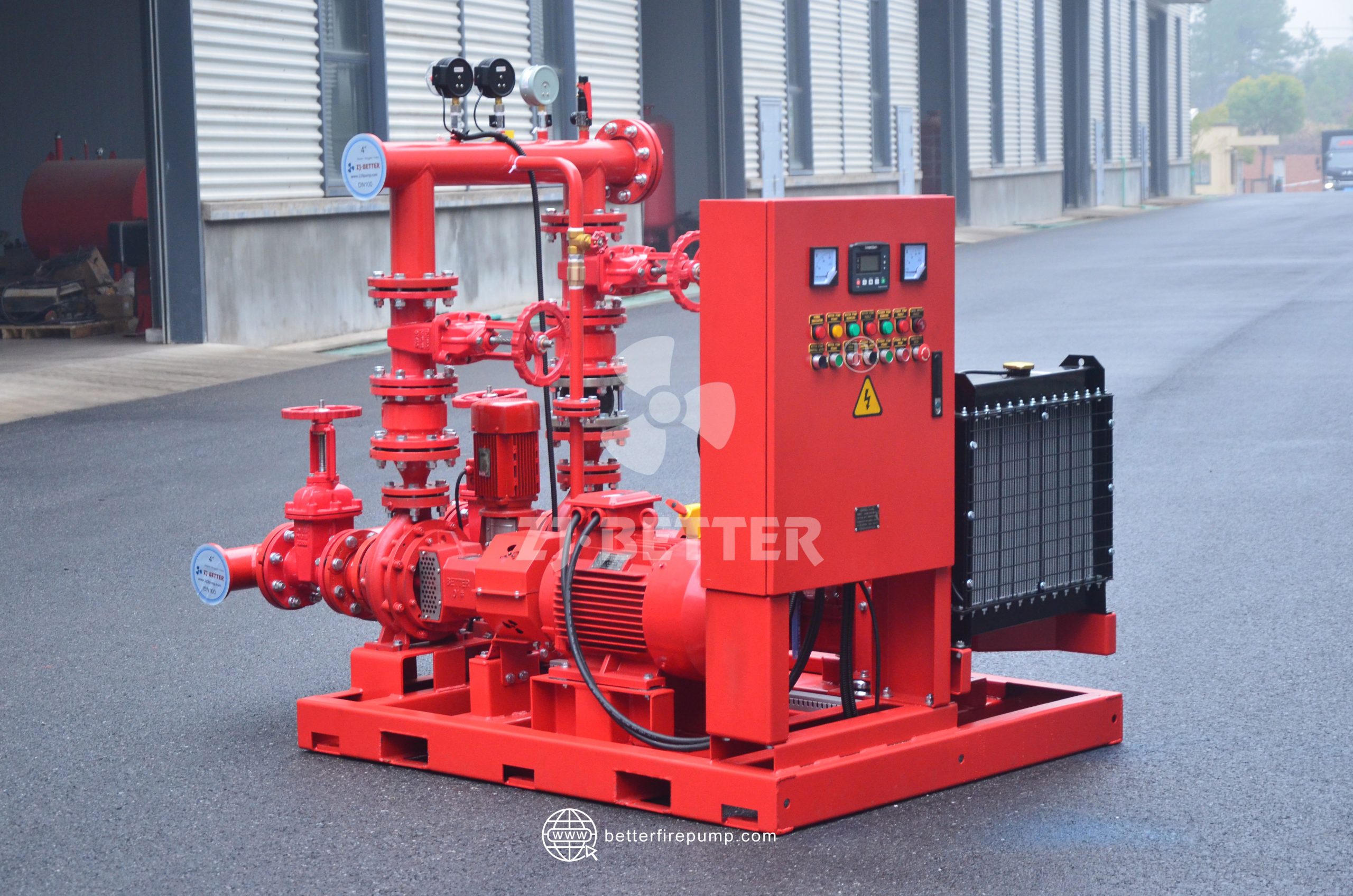

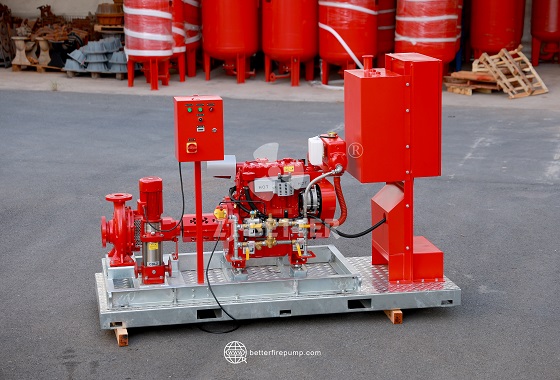

This high-efficiency vertical pipeline fire pump system is designed specifically for fire protection projects with limited space. It features a small footprint, high head, and stable operation, integrating intelligent control and reliable water supply capabilities. It is suitable for high-rise buildings, underground spaces, and densely populated urban fire protection projects.

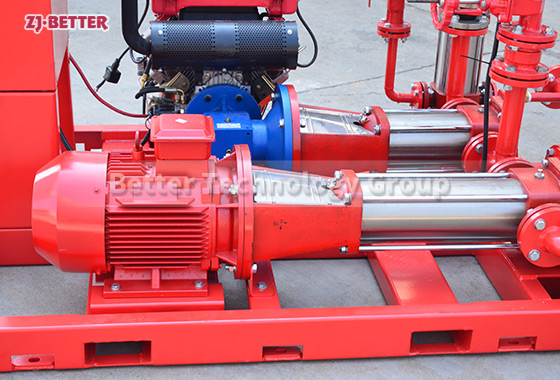

Vertical inline fire pump systems offer solutions for fire protection projects in limited spaces, primarily addressing the needs of high-density urban buildings, existing building renovations, underground spaces, and equipment rooms with limited area. Through structural optimization, system integration, and performance enhancement, these systems achieve efficient, stable, and continuous fire water supply without compromising fire safety standards. These vertical inline fire pump systems feature a vertical design with coaxial inlet and outlet ports, allowing for direct installation into piping systems. This significantly reduces the axial installation length and foundation footprint required by traditional horizontal pumps, making them particularly suitable for underground pump rooms, rooftop equipment floors, narrow equipment rooms, and engineering environments with limited height. The complete unit typically consists of a vertical fire main pump, a pressure maintenance pump, piping components, valves and instruments, and an intelligent control system. Each functional module is highly integrated, resulting in a compact yet logically clear structure, facilitating quick on-site installation and subsequent operation and maintenance. In terms of performance, the vertical inline fire pump utilizes a high-efficiency hydraulic model design. Through precise calculation of impeller flow channel angles and pump casing structure, it achieves a comprehensive advantage of high head, high flow rate, and high efficiency under rated operating conditions, enabling rapid system pressure build-up during the initial stages of a fire, providing reliable water supply for sprinkler systems, fire hydrant systems, and other fire extinguishing facilities. The pump body is typically made of high-strength cast iron or ductile iron, and key flow-through components are treated with anti-corrosion and wear-resistant coatings, allowing for long-term operation in humid, high-temperature, or complex water quality environments, effectively extending equipment life and reducing failure rates. The vertical structure also results in more balanced stress on the pump shaft, leading to low vibration and noise during operation, which improves the overall stability of the fire protection system, making it particularly suitable for residential buildings, hospitals, commercial complexes, and public buildings with stringent environmental requirements. In terms of system reliability, these fire pump units are usually equipped with dedicated fire protection motors, possessing excellent overload capacity and high-temperature resistance, ensuring continuous operation in emergency situations. The pressure maintenance pump automatically regulates daily pipeline pressure, preventing frequent starting and stopping of the main pump, thereby reducing mechanical wear and extending the overall system lifespan. As the core component of the entire system, the control system features automatic, manual, and remote control functions. It can automatically start and stop the main pump and pressure-regulating pump based on pressure changes, and provides real-time monitoring and display of voltage, current, operating status, and fault information. This allows managers to quickly understand the system’s operating conditions, improving the intelligence level of fire safety management. Addressing the common challenges of complex construction and dense piping in confined spaces, the vertical inline fire pump system can be customized during the design phase based on site conditions. By rationally planning pipe routing and equipment layout, it reduces elbows and additional resistance, improving hydraulic efficiency and reducing energy consumption at the system level. Furthermore, this type of system offers significant advantages in installation and maintenance. Due to the vertical arrangement of the pump and motor, it occupies a small footprint and is easy to disassemble and assemble. Routine maintenance does not require extensive removal of surrounding facilities, significantly reducing maintenance costs and downtime. In terms of safety performance, the vertical inline fire pump system is designed and manufactured in strict accordance with relevant fire safety regulations, ensuring stable output under rated pressure and extreme operating conditions. This prevents reduced fire water supply capacity due to limited space, fundamentally guaranteeing the safety of personnel and property. Overall, the vertical inline fire pump system, through its compact design, high-efficiency performance, stable and reliable operation, and intelligent control scheme, provides a comprehensive solution for fire safety projects in confined spaces that balances safety, practicality, and economy. It not only meets the high standards and reliability requirements of modern buildings for fire safety systems but also aligns with the trend of high-density and intensive development of urban buildings, demonstrating broad application prospects in various new and renovated fire protection projects.