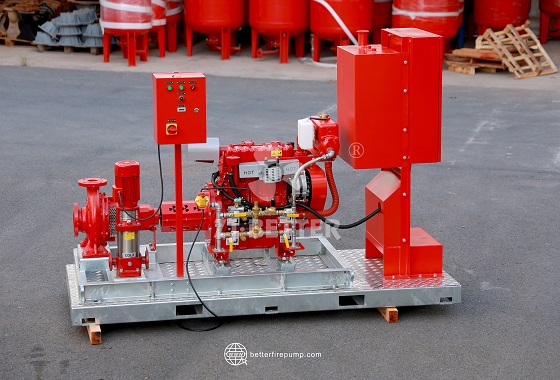

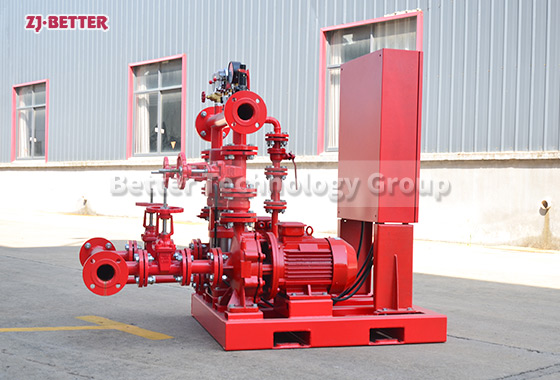

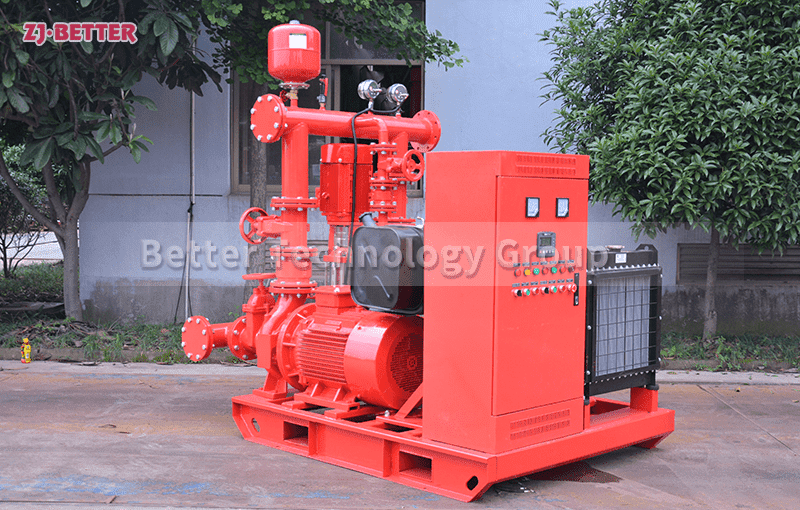

Home » Fire Pump Set » Can a fire pump run without water?

Can a fire pump run without water?

No, a fire pump should never run without water. Running a fire pump dry can cause significant damage to the pump’s internal components, leading to overheating and failure. Ensuring the water supply is reliable and monitored is essential for proper fire pump operation.

Contact US

Get Price

Share:

Content

No, a fire pump should never run without water. Running a fire pump dry can cause significant damage to the pump’s internal components, leading to overheating and failure. Ensuring the water supply is reliable and monitored is essential for proper fire pump operation.Can a fire pump run without water?

Inquiry

More Fire Pump Set