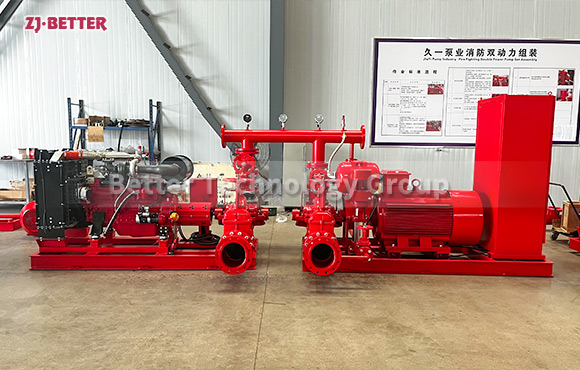

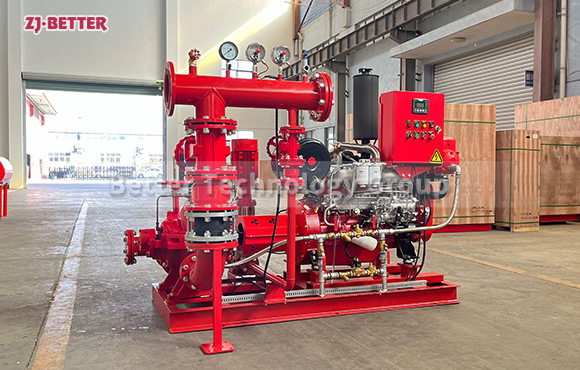

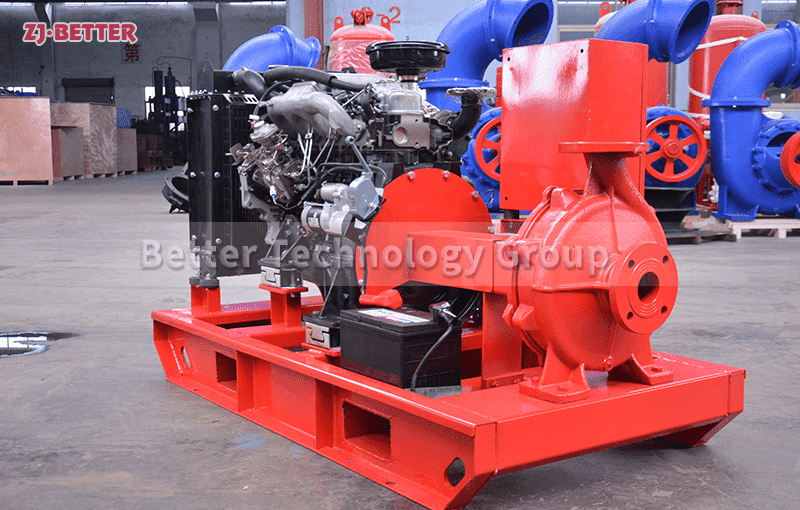

Diesel engine emergency fire pump product introduction

XBC diesel engine fire pump set is in accordance with the standard GB6245-2006 “Fire Pump Performance Requirements and Test Methods”. This series of products has a wide range of head and flow, which can fully meet the fire water supply in various occasions of industrial and mining enterprises such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, and textiles. The advantage is that the electric fire pump cannot be started after the power system of the building suddenly loses power, and the diesel engine fire pump is automatically started and put into emergency water supply.

1. Control mode: manual/automatic, remote control function supports manual control, automatic control, remote control of pump start and stop, control mode can be switched;

2. Time setting: You can set the control time of the diesel engine, including: start delay time, preheating or pre-sliding time, start cut-off time, start cut-off speed, rapid running time, speed-up process time, cooling down time;

3. Alarm shutdown: automatic alarm and shutdown items: no speed signal, overspeed, low speed, low oil pressure, high cooling temperature, start failure, shutdown failure, oil pressure sensor open/short circuit, water temperature sensor open/short circuit, speed sensor open circuit /short circuit, water pump water pressure is too low, etc.