Relevant performance characteristics of diesel engine fire pump

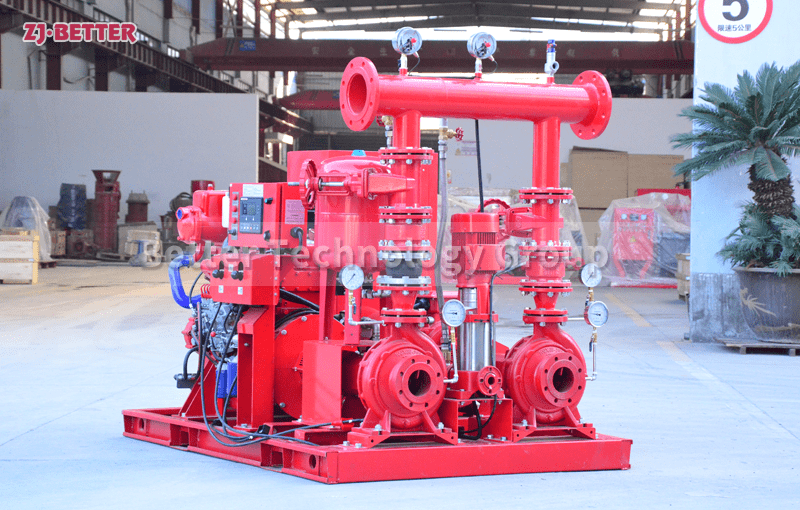

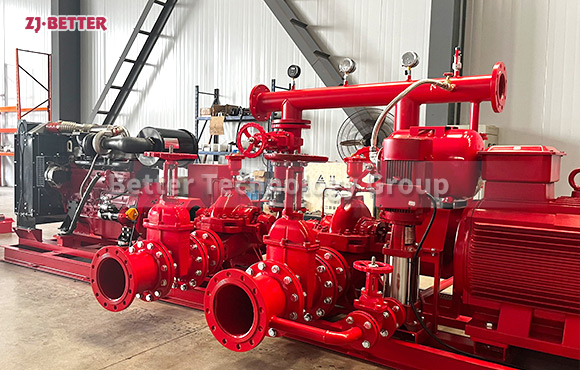

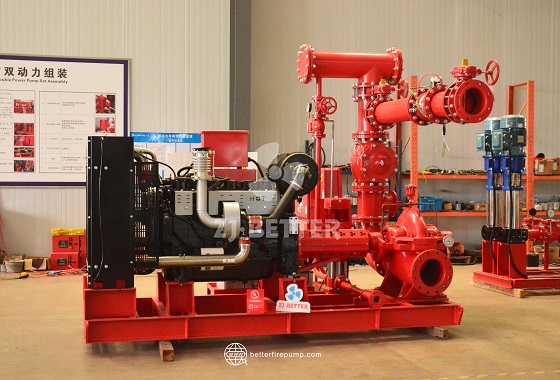

Diesel engine fire pumps can be used to transport clear water below 80°C without solid particles or liquids with physical and chemical properties similar to water. On the premise of meeting the fire protection conditions, the requirements of the living and production water supply conditions are taken into account. The products can be used not only in independent fire water supply systems, but also in fire protection and domestic shared water supply systems, as well as in construction, municipal, industrial and mining, water supply and drainage, ships, field operations and other occasions.

Diesel engine fire pumps used for fire fighting purposes are relatively strict. Generally, two sets of batteries are equipped with double backup to ensure the normal operation of diesel engine fire pumps. When the controller can run normally, it will send a signal to the starter motor. There are also two types of starter motors, one is manual and the other is automatic.

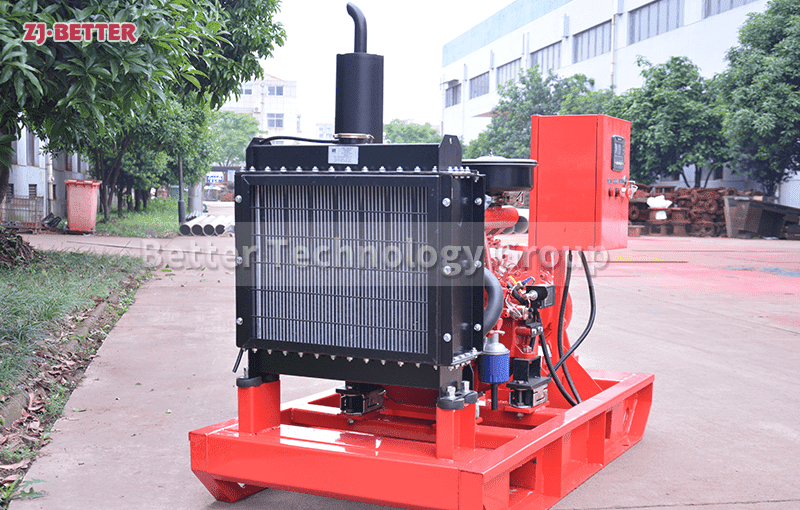

If the starter motor can operate normally, then feed back a signal to the controller, and then the controller sends a signal to the speed control board, and the speed control board controls the throttle driver to supply oil to the oil pump. After entering the oil, the air is compressed and the diesel is burned to do work, so that the diesel engine starts to do work to start.

The connection between the diesel engine and the water pump is somewhat different from the traditional one, which uses a clutch. Why use a clutch, because when the water pump is empty, it needs a lot of force to drive it, and the function of the clutch is to share the two, first start the diesel engine, the diesel engine is running, and then the water pump is sucked in through the clutch, Drive the operation of the water pump. But the problem is that the use of the clutch is very inconvenient for maintenance, and the clutch does not have an oil lubrication system, so the damage is relatively serious.