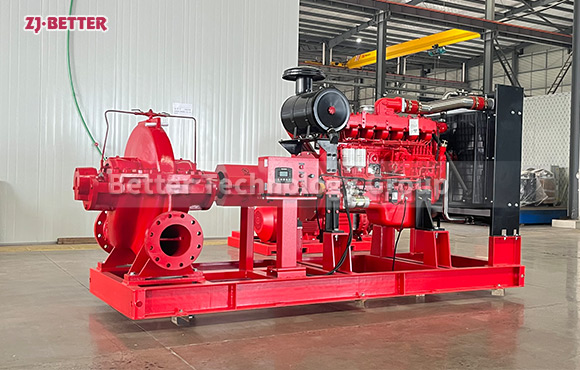

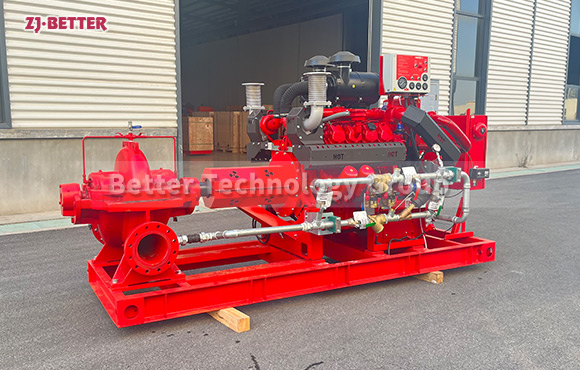

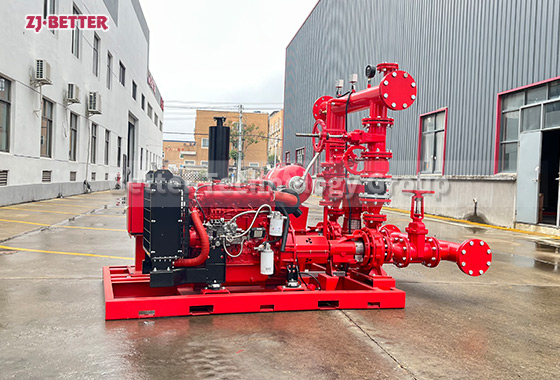

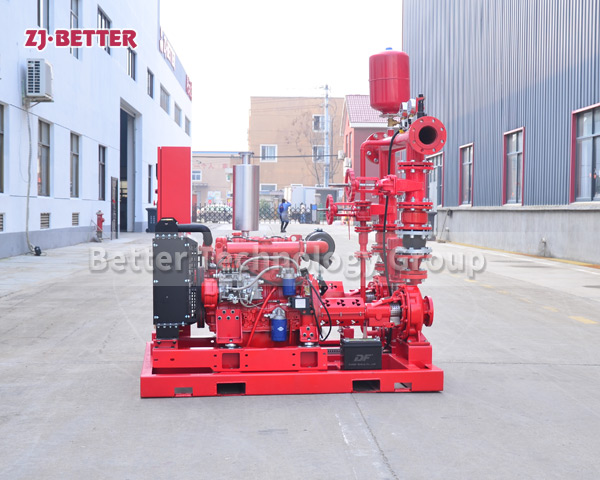

Smart and Safe Container Fire Pump System: Combining Efficiency, Energy Saving, and Stable Operation

The intelligent container fire protection system combines efficient diesel pumps, automatic control, and modular design, offering independent operation, energy conservation, environmental protection, and convenient transportation. It’s ready for installation and use, suitable for petrochemical, port, data center, and remote engineering projects, providing reliable fire protection and intelligent safety solutions for various locations.

The containerized fire protection system, emphasizing both intelligence and safety, is a modern firefighting system that integrates efficient protection, energy-saving operation, and intelligent control. Using a container as its carrier, it integrates a diesel fire pump, electronic control system, piping system, and auxiliary equipment into a sealed and rugged modular space. This system offers multiple advantages, including ready-to-use, flexible mobility, and stable performance. Designed for diverse and complex environments, this system is widely used in petrochemical bases, energy storage and transportation, ports and terminals, data centers, factory workshops, field operations, and projects located far from municipal water supply networks, providing reliable fire protection for a wide range of locations. The containerized fire protection system utilizes a standardized container shell, enabling extreme flexibility in transportation, installation, and deployment. Whether transported by land, sea, or rail, the system can be quickly moved to its destination and put into operation, significantly improving the efficiency of firefighting system deployment. The system’s rational internal layout compactly houses the diesel engine, water pump, control cabinet, water inlet and outlet piping, and ventilation system. A shock-absorbing base and fixed structure ensure stable and reliable operation over extended periods of operation. The container’s interior is constructed of corrosion-resistant and fireproof materials, offering excellent insulation and noise reduction, ensuring safe operation even in harsh environments. The firefighting system is powered by a high-efficiency diesel engine, capable of independent operation even in the event of a complete power outage or interruption of the municipal water supply. The diesel engine boasts strong starting performance and low fuel consumption, driving the fire pump to rated flow and pressure within seconds, ensuring rapid and sufficient firefighting water supply in the early stages of a fire, buying valuable time for extinguishing the flames. The high-performance fire pump, manufactured from high-quality materials, is resistant to high temperatures, corrosion, and wear, offering high efficiency and low maintenance requirements. The system is designed to comply with international standards, such as NFPA 20, ISO, and EN, and can be configured to meet the firefighting requirements of different regions, ensuring stable global operation. Another highlight of this system is its intelligent control system. The system incorporates advanced PLC automation technology, enabling automatic start and stop, data monitoring, fault alarms, and remote management. The control cabinet features a high-resolution touchscreen interface, providing a user-friendly interface and ease of operation. The system monitors key parameters such as engine speed, oil pressure, water temperature, pump outlet pressure, and flow rate in real time, and automatically records operating data for easy maintenance and management. In the event of an abnormality, the system automatically issues an audible and visual alarm and initiates an emergency shutdown to prevent equipment damage or malfunction. Furthermore, through an IoT communication module, the system can connect to a remote monitoring center for remote start/stop control, status query, and data upload. This allows managers to monitor equipment status in real time from anywhere, significantly enhancing the intelligence of firefighting management. Energy conservation and environmental performance are also core strengths of the system. The high-efficiency diesel engine optimizes combustion efficiency while reducing emissions, meeting international environmental standards. The pump design utilizes a fluid-optimized structure to minimize energy loss. The system’s intelligent piping layout minimizes pressure loss, ensuring high efficiency while reducing fuel consumption and carbon emissions, in line with modern green energy conservation concepts. The container firefighting system also excels in operational safety. The entire system is equipped with comprehensive fire and explosion protection and ventilation systems. Automatic vents and exhaust fans are installed within the container to ensure complete fuel combustion and temperature control. The fuel system features anti-leakage and automatic shut-off devices to effectively prevent fuel leaks and fire hazards. The electronic control system is waterproof and dustproof, ensuring long-term stable operation in humid, hot, and low-temperature environments. The system has undergone numerous safety tests and field verification to ensure reliable startup and continuous water supply in any emergency situation. The system is also extremely convenient to install and maintain. Due to its high level of integration, the equipment is fully assembled and tested before shipment. Users simply transport the container to the designated location, connect the water and oil lines, and it’s ready for operation, eliminating the need for complex on-site construction. This modular design significantly shortens installation time and reduces project costs, while also minimizing the risks of installation errors. Regarding maintenance, the spacious and well-planned interior of the container, with access to maintenance channels, facilitates regular inspection and maintenance of the diesel engine, pump, piping, and control system, significantly improving maintenance efficiency and service life. This firefighting system is not only widely used in the industrial and energy sectors, but also plays a vital role in remote areas, temporary construction sites, military bases, and other environments without fixed firefighting infrastructure. With its independent operation capabilities, powerful power output, and rapid response, it can provide a continuous and stable firefighting water source at any time and in any location, providing a solid guarantee for the safety of life and property. Overall, the containerized firefighting system, which prioritizes both intelligence and safety, represents a technological trend in modern firefighting equipment. Its modular, automated, and environmentally friendly design meets the urgent need for efficient, safe, and energy-efficient firefighting equipment. It transforms the complex installation and fixed location limitations of traditional firefighting systems into a flexible and mobile solution, while intelligent control and remote management ensure more precise and reliable operation. Whether used for the security protection of large-scale industrial facilities, emergency response at energy bases, or temporary firefighting deployments on remote engineering projects, this system has demonstrated exceptional adaptability and operational performance, making it an indispensable component of modern firefighting systems.

管道泵(不锈钢304316L).jpg)