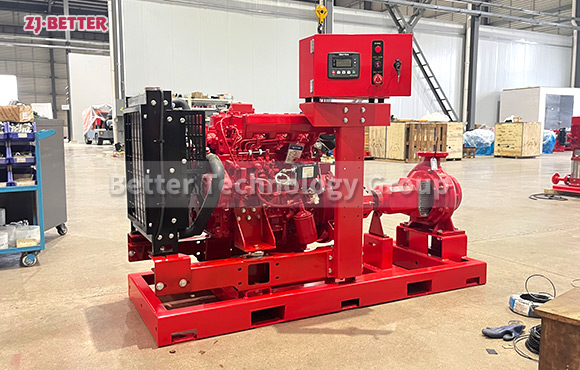

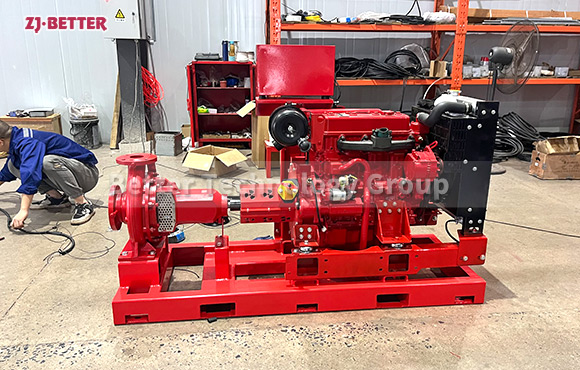

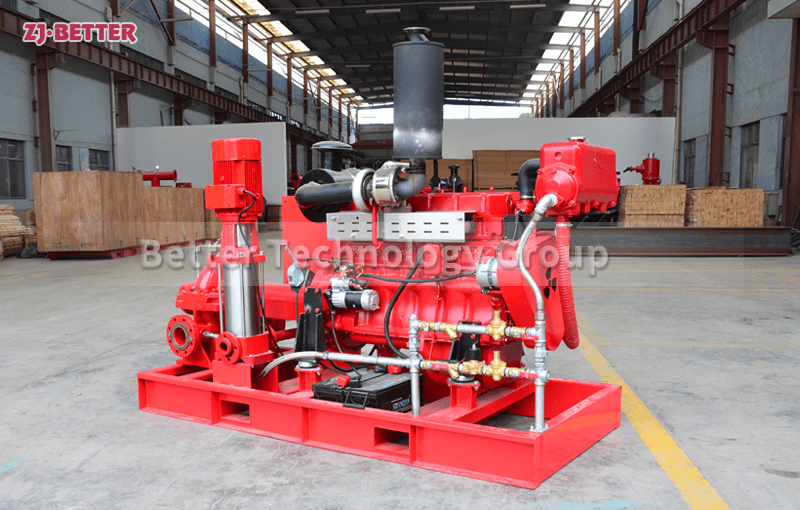

XBC-IS Diesel Engine Fire Pump Set

The diesel engine fire pump set adopts ISW pump.

1. The pump is the horizontal structure, the inlet and outlet are the same in diameter, and lying in the same center line, which can be installed in the pipeline as valve, the floor space needed is small, if the protection cover is added, it can be put in the open air;

2. The impeller is installed on the major axis of the motor directly, the axial is short in size, the structure is compact, can calibrate radial and axial load that produced by pump rounding effectively, thus guaranteed the pump operating steadily, vibration, and low noise;

3. The axle seal adopts machinery seal or machinery seal sets, uses imported titanium alloy sealed ring, medium-sized high-temperature resistance machinery seal and adopts the hard alloy material, wear-resisting seal, which can lengthen the life of machinery seal effectively;

4. It is convenient to install and overhaul, no need to dismantle or move pipeline system; just lifting off pump conjunction flat nut can take all rotor parts out;

5. Can choose series or parallel operation according to your requirements for flow and lift;

6. Can be installed horizontally according to the pipeline system requirement.

ISW series horizontal single-stage single-suction centrifugal pump is a new generation of energy saving, environment friendly horizontal centrifugal pump researched and developed by our company, which absorbs advanced technology of similar products abroad and adopts domestic general performance parameters of centrifugal pumps.

In addition, according to different operation temperatures and mediums, we developed the hot-water pump(ISWR), corrosion-resistant chemical pump(ISWH) and oil pump (ISWB). This pump enjoys excellent performance, good reliability, long operation life, reasonable construction and nice appearance, which is outstanding in the industry.

Main Features

1. The pump is the horizontal structure, the inlet and outlet are the same in diameter, and lying in the same center line, which can be installed in the pipeline as valve, the floor space needed is small, if the protection cover is added, it can be put in the open air.

2. The impeller is installed on the major axis of the motor directly, the axial is short in size, the structure is compact, can calibrate radial and axial load that produced by pump rounding effectively, thus guaranteed the pump operating steadily, vibration, and low noise.

3. The axle seal adopts machinery seal or machinery seal sets, uses imported titanium alloy sealed ring, medium-sized high-temperature resistance machinery seal and adopts the hard alloy material, wear-resisting seal, which can lengthen the life of machinery seal effectively.

4. It is convenient to install and overhaul, no need to dismantle or move pipeline system; just lifting off pump conjunction flat nut can take all rotor parts out.

5. Can choose series or parallel operation according to your requirements for flow and lift.

6. Can be installed horizontally according to the pipeline system requirement.