The XBC-ZWC Diesel Engine Self-priming Pump: your trusted companion.

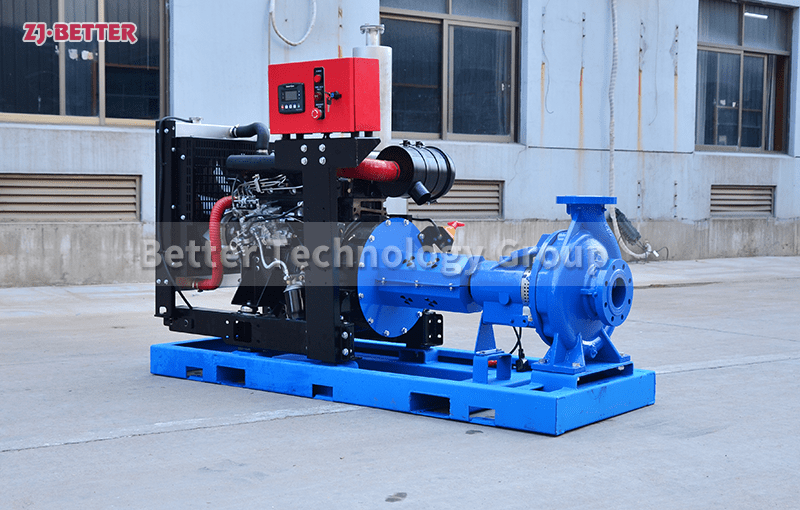

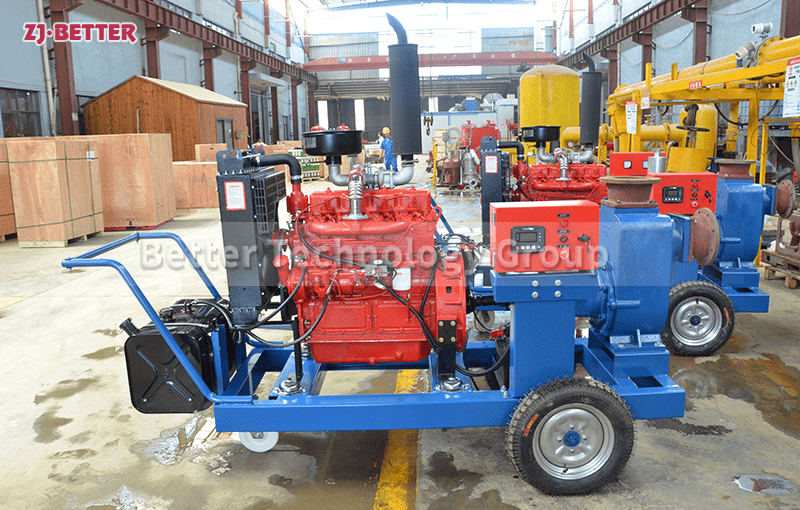

The XBC-ZWC Diesel Engine Self-priming Pump is a powerful and versatile solution for various water transfer applications. Designed with reliability and efficiency in mind, this self-priming pump is specifically engineered to handle water transfer tasks with ease. Whether you need to move water from one location to another, drain flooded areas, or supply water for irrigation, the XBC-ZWC Diesel Engine Self-priming Pump is your trusted companion.

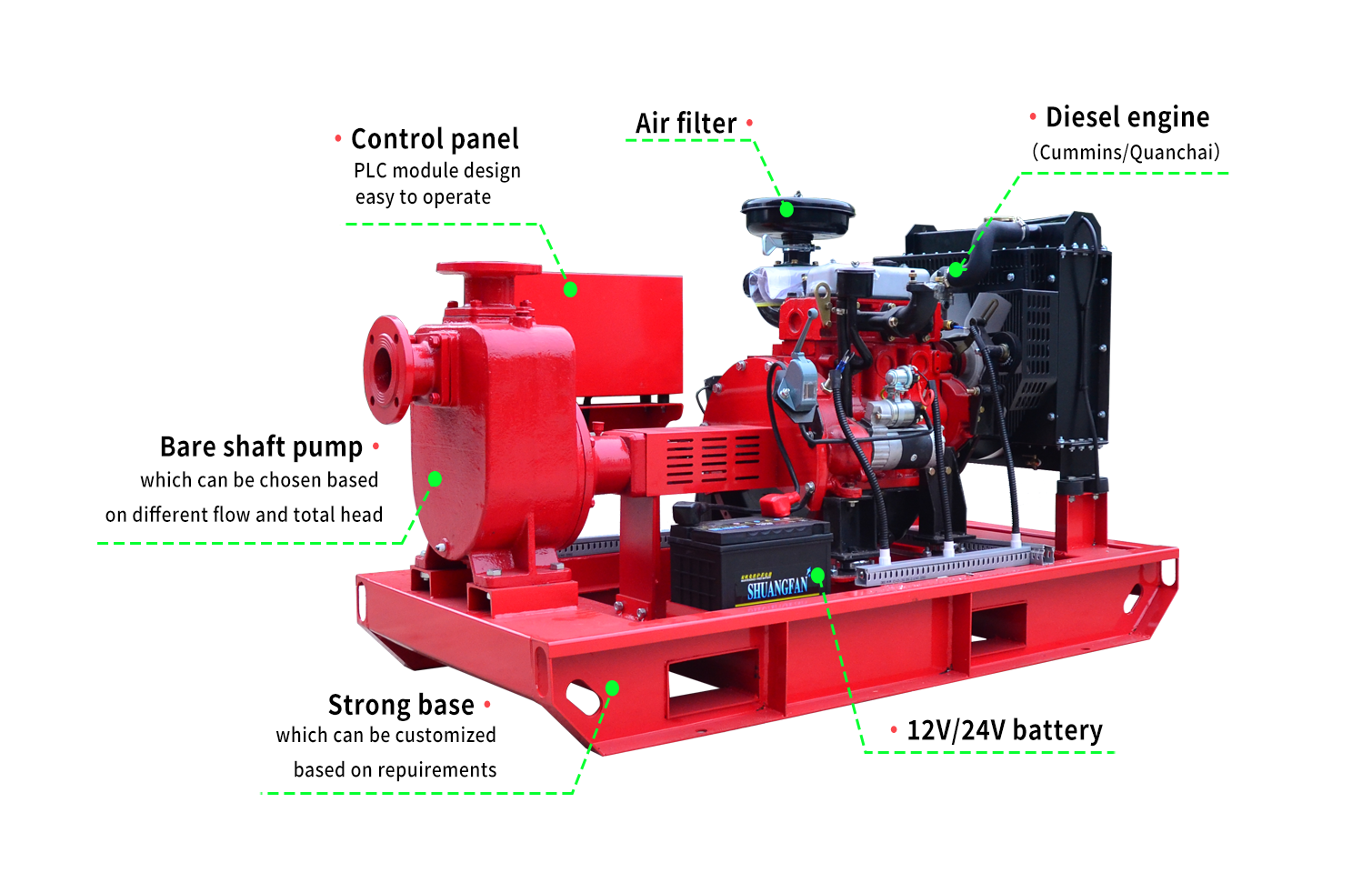

Key Features:

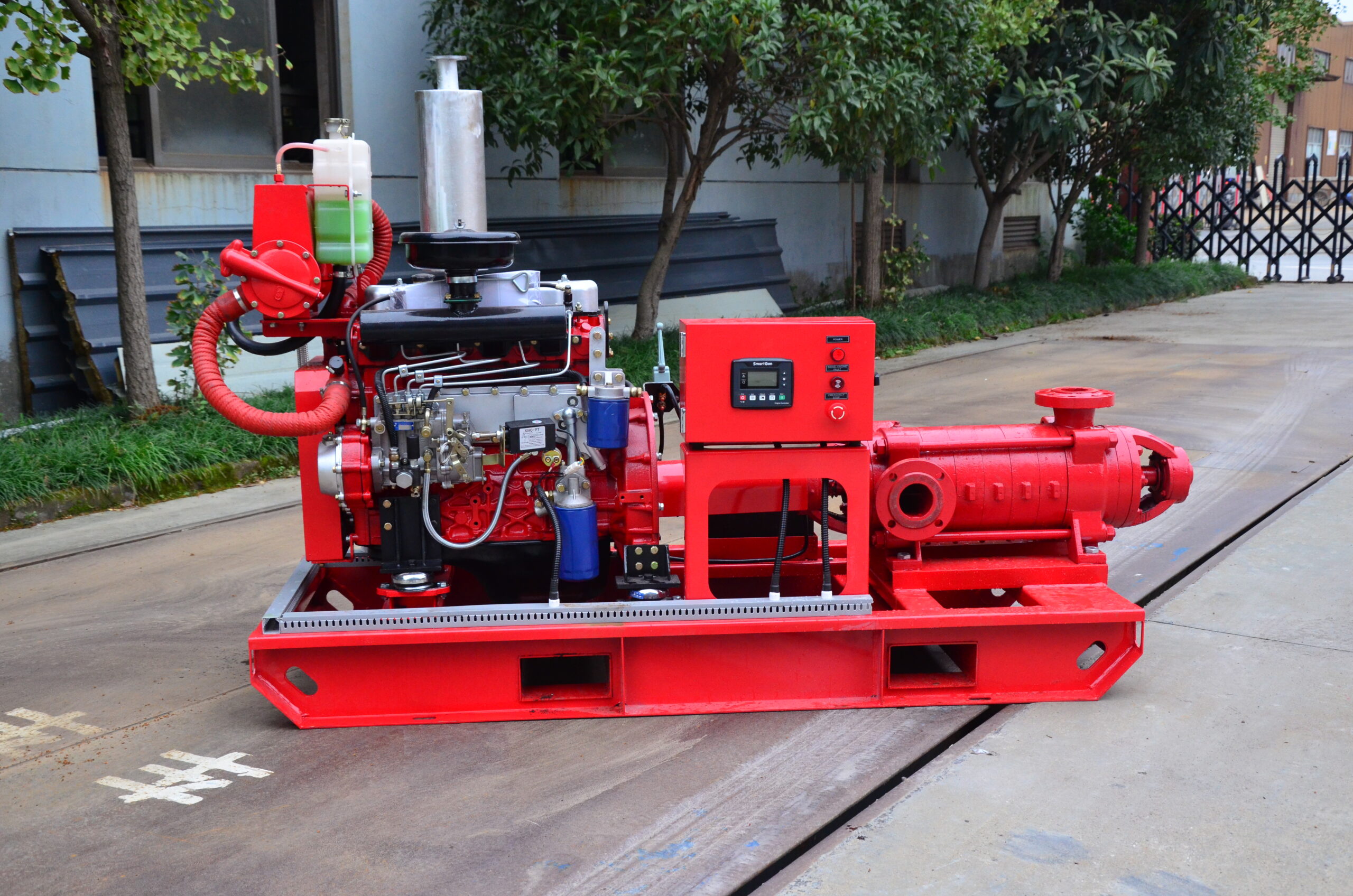

1.Self-Priming Capability: With its advanced self-priming design, the XBC-ZWC Diesel Pump can quickly and effectively remove air from the suction pipe, allowing for effortless priming and ensuring a continuous flow of water.

2.Efficient Diesel Engine: Powered by a high-performance diesel engine, this pump delivers reliable and efficient operation. The diesel engine provides a stable power source, allowing the pump to operate in various environments and challenging conditions.

4.Robust Construction: Built to withstand tough working conditions, the XBC-ZWC Diesel Self-priming Pump features a rugged construction that ensures durability and longevity. It can handle abrasive and corrosive materials, making it suitable for a wide range of applications.

4.Easy to Operate: Equipped with user-friendly controls and a simple interface, this pump is easy to operate even for those with minimal technical expertise. Its intuitive design allows for quick setup and hassle-free operation, saving you time and effort.5.

5.Versatile Applications: The XBC-ZWC Diesel Self-priming Pump is suitable for a variety of applications, including agricultural irrigation, construction sites, dewatering flooded areas, water transfer for firefighting operations, and more. It provides a reliable and efficient solution for your water transfer needs.