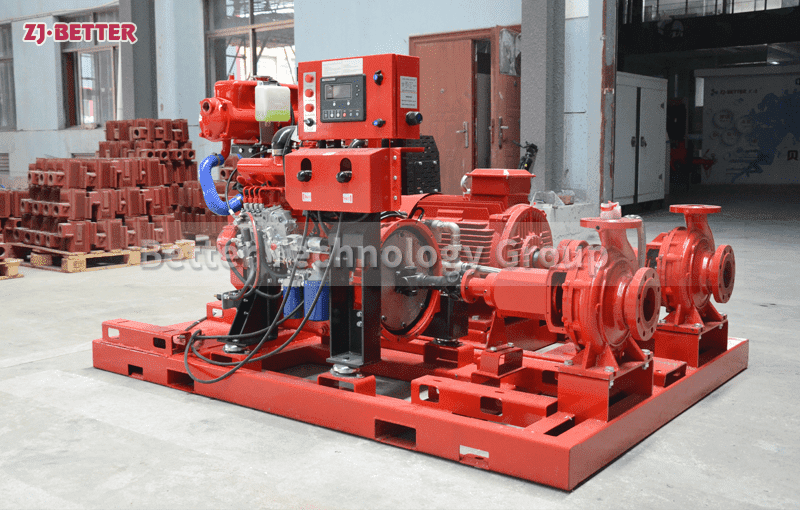

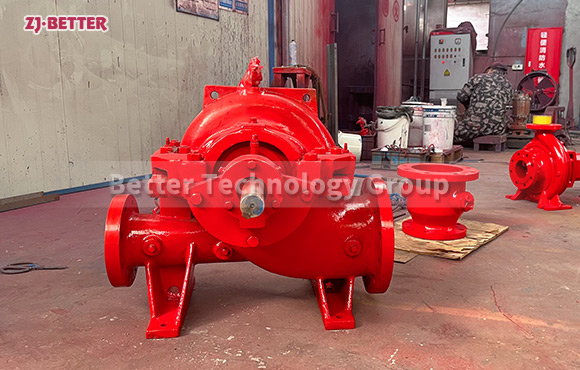

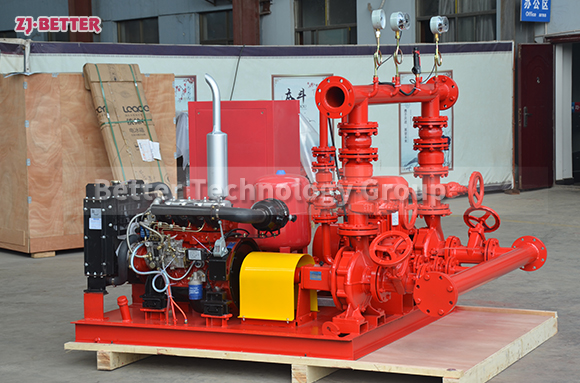

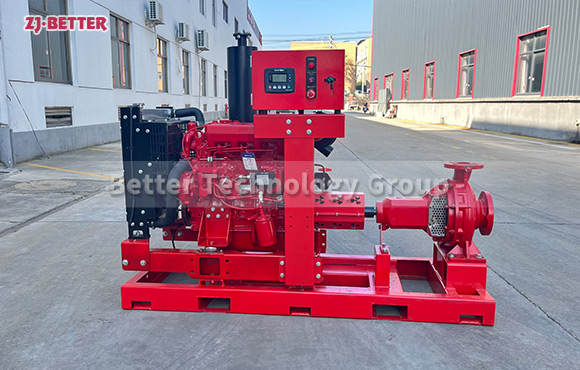

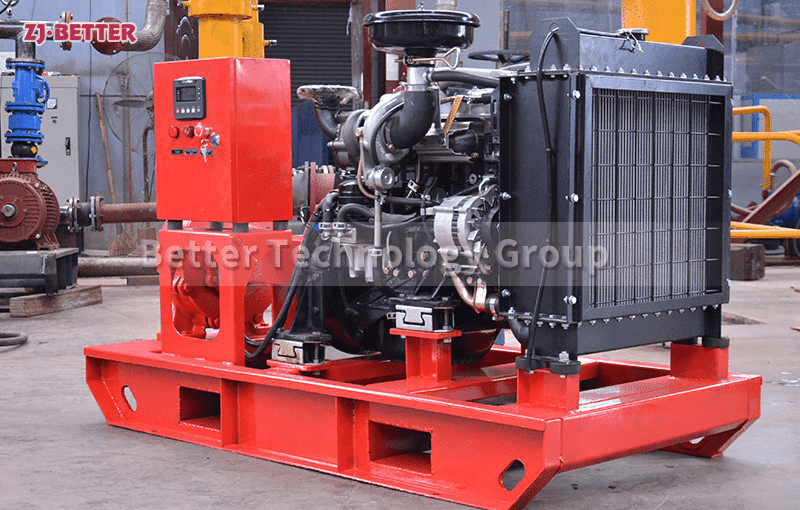

Diesel engine fire pump set is compact and reasonable in structure

The diesel engine fire pump set has the characteristics of good starting characteristics, strong overload capacity, compact and reasonable structure, convenient maintenance, simple and reliable use, etc. The unit is equipped with protection functions such as overspeed, low oil pressure, three start failures, high water temperature, low oil level, and low battery voltage. At the same time, it can be connected with the customer’s automatic fire alarm device or the centralized control cabinet of the fire protection system to realize the function of remote monitoring.

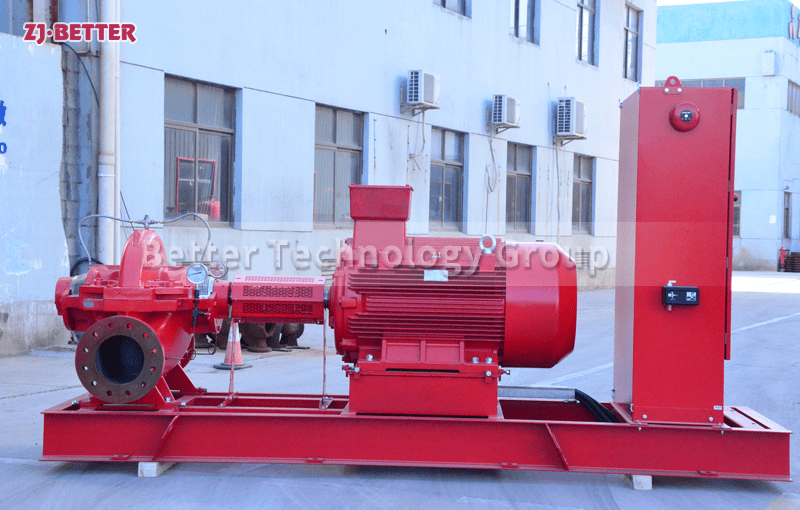

The diesel engine pump set is powered by 10-1000KW series diesel engines produced by Cummins and domestic well-known diesel engine manufacturers. It is assembled with the water pump through high-elastic couplings, clutches, reducers, etc., and has the characteristics of quick start, reliability, strong emergency response capability, compact structure, and convenient protection. It has the functions of manual, automatic, automatic switching, automatic charging, automatic protection (overspeed, low oil pressure, three start failures, high water temperature, low battery voltage alarm, shutdown protection, etc.), emergency lighting, remote monitoring connection and other functions. In order to ensure the normal operation of the unit in a cold climate below 5°C, the unit can be equipped with a cooling water preheating device.