How Does an Intelligent Control System Enhance Fire Pump Safety?

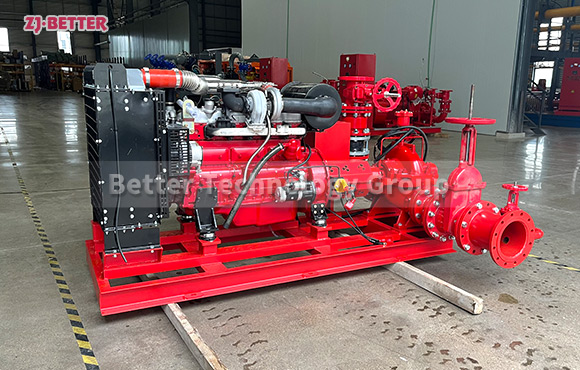

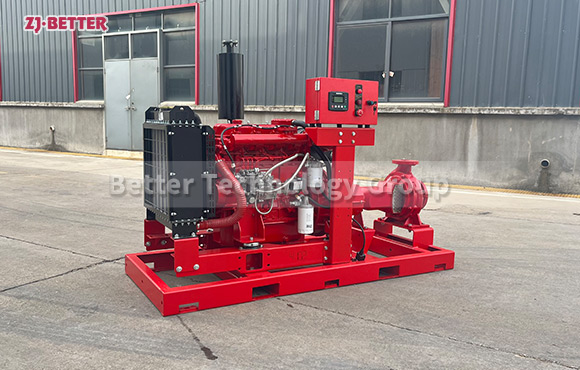

This fire pump unit is equipped with an advanced intelligent control system, enabling automatic start/stop, real-time status monitoring, and fault alarms to significantly enhance operational safety and reliability. The system includes multiple protection features such as overload protection, phase failure alert, and abnormal water pressure detection, ensuring rapid response and stable water supply during fire emergencies. The user-friendly control panel supports remote monitoring and data logging, making management and maintenance more efficient. Whether for commercial buildings or industrial facilities, this intelligent system provides strong support for fire safety assurance.

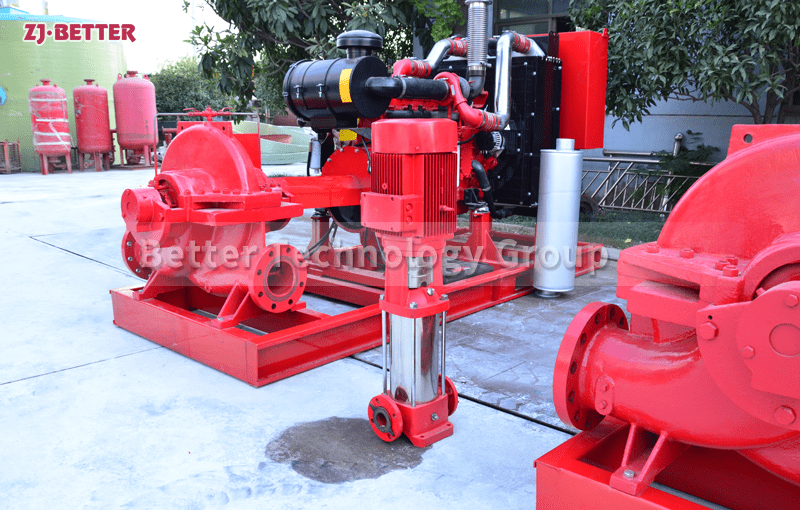

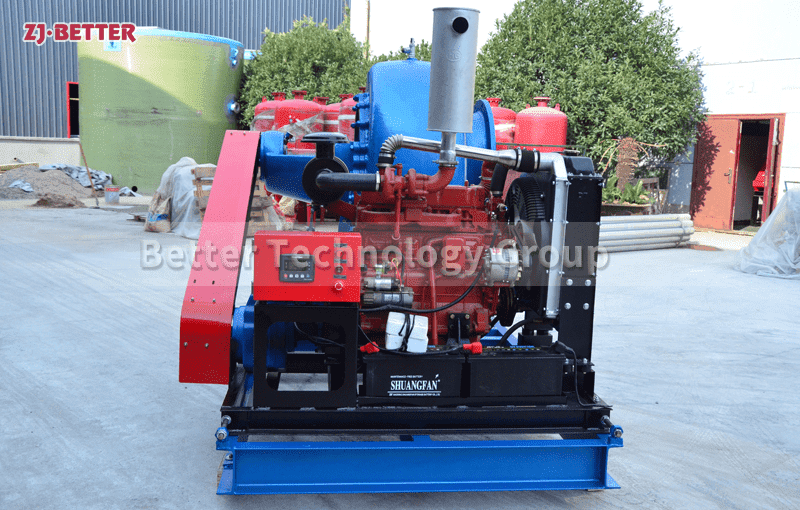

We are dedicated to the development and manufacturing of high-performance fire pump systems, providing efficient and reliable fire protection solutions for buildings and industrial applications. Our product range includes electric pump sets, diesel engine pump sets, integrated control panels, and pressure maintenance devices, widely used in high-rise buildings, factories, warehouses, energy sectors, and chemical industries.

The equipment features advanced hydraulic designs and precise manufacturing, offering large flow capacity, high head, low noise, and strong durability. Integrated with intelligent control technology, the system supports fully automatic start/stop, real-time fault detection, and remote monitoring—greatly enhancing firefighting responsiveness and system reliability.

Compact structure, easy installation, and modular customization allow flexibility for diverse project requirements. With multi-level protection design, the system ensures stable performance even in harsh environments, significantly improving overall safety assurance.

With outstanding performance, strict quality control, and continuous innovation, our products have earned widespread customer trust and are the ideal core components of modern fire protection systems.