Protection and maintenance of diesel engine fire pump

Since the operation of the electric water pump is inseparable from electricity, and the power supply is often cut off at the scene of a fire accident or the power supply is automatically closed due to the fire, even if we are equipped with a dual power supply switching device, it is really impossible to ensure that the power grid must be normal when the fire alarm signal comes.

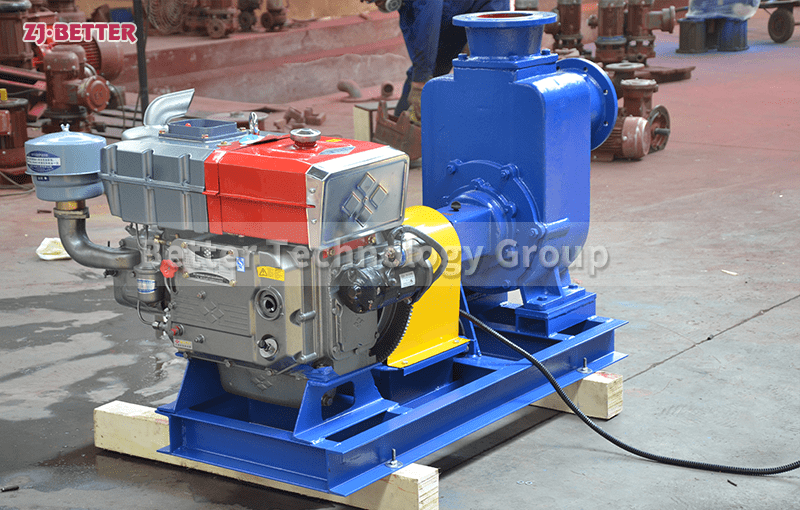

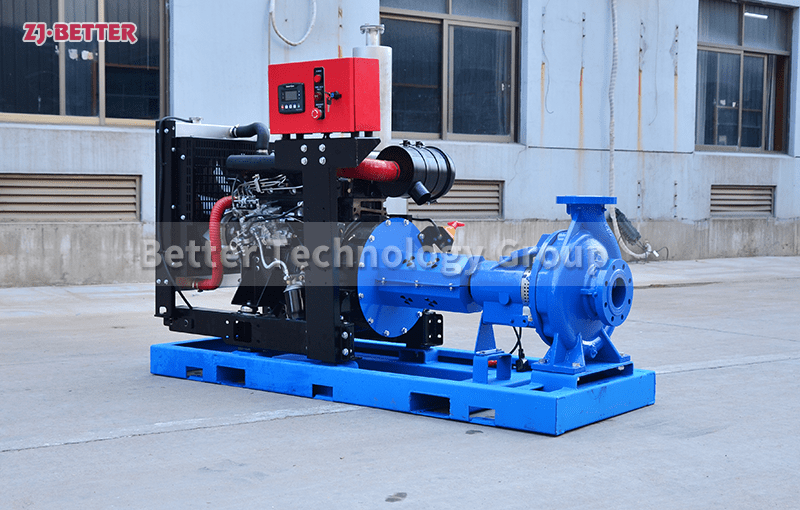

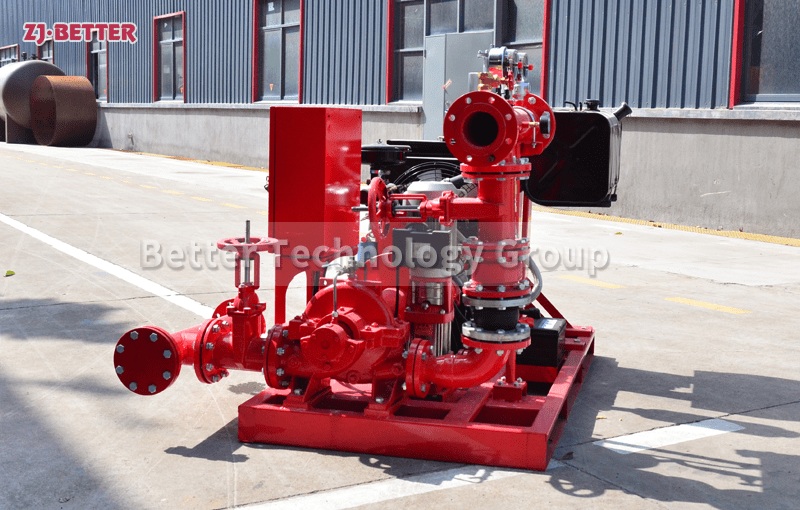

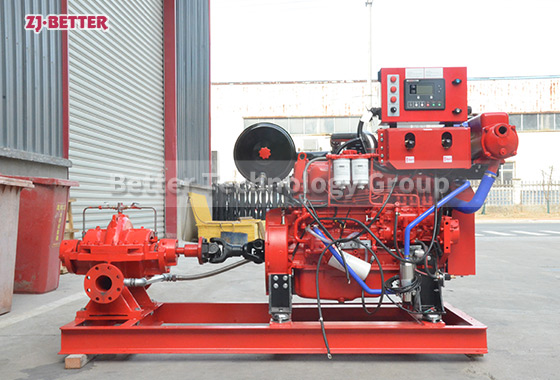

Therefore, starting and running a diesel engine fire pump completely disconnected from the grid becomes the preferred equipment for backup fire protection facilities! The driving power of diesel engine fire pumps is completely different from that of electric water pumps, so their daily protection and treatment are also different in many places! The characteristics of diesel engine fire pump: The biggest difference between diesel engine fire pump and electric water pump is that it has its own independent power supply system – storage battery. Therefore, the start and operation of diesel engine fire pump can be completely separated from the mains.

1. Protection and maintenance of diesel engine fire pump

The correct maintenance of the diesel engine fire pump, especially the preventive maintenance, is easy and economical maintenance, so it is the key to prolong the service life and reduce the cost of use. Daily maintenance can be carried out according to the following steps to check the amount of fuel in the fuel tank – check the amount of fuel stored in the fuel tank and add it as needed.

2. Preparation for starting the diesel engine fire pump

Diesel engine fire pumps are much more complicated in structure than electric water pumps, so the preparatory work before starting is also more cumbersome.

First, we should first check whether the display of the voltmeter on the control cabinet is 24V. If it is lower than 24V, we should find out the reason in time and eliminate the fault.

Second, check whether all parts of the diesel engine are normal, whether the accessories are reliably connected, and eliminate abnormal phenomena.

Third, check whether the oil in the oil pan, fuel injection pump and governor reaches the specified oil level.

3. Inspection of diesel engine fire pump

In order to improve the response ability of the diesel engine fire pump to the fire signal, it is recommended to inspect it once a week. the

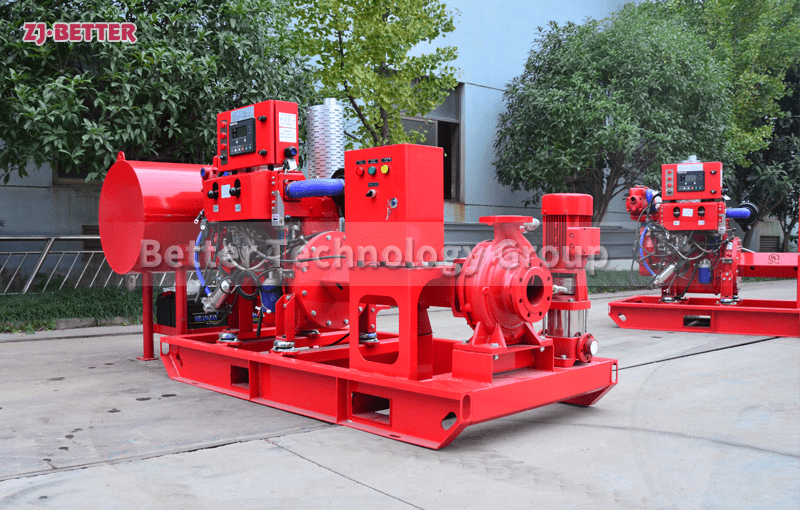

4. Daily management of diesel engine fire pumps

To ensure the reliability of the entire control system, perfect daily management is inseparable.

5. The high automation function of the diesel engine fire pump and its control cabinet makes the whole set of equipment reach the goal of unattended, and better meet the user’s requirements for fire-fighting equipment.