Unleash Unparalleled Fire Suppression Power with XBC-OTS Split Case Pump!

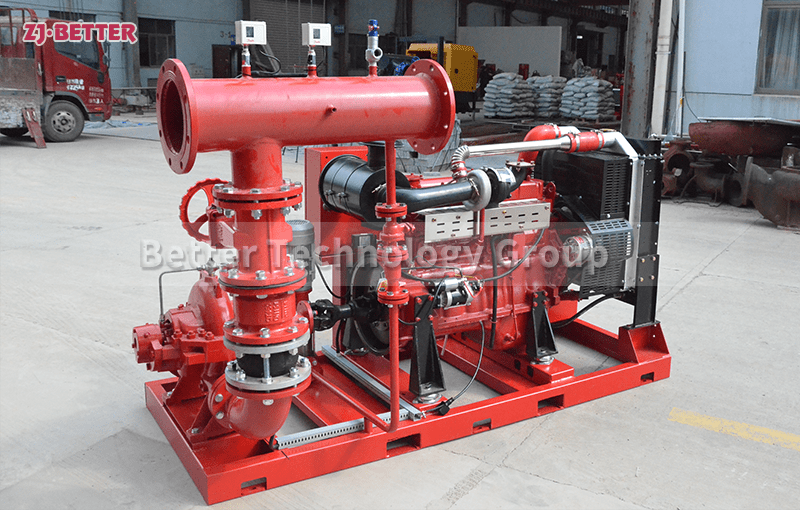

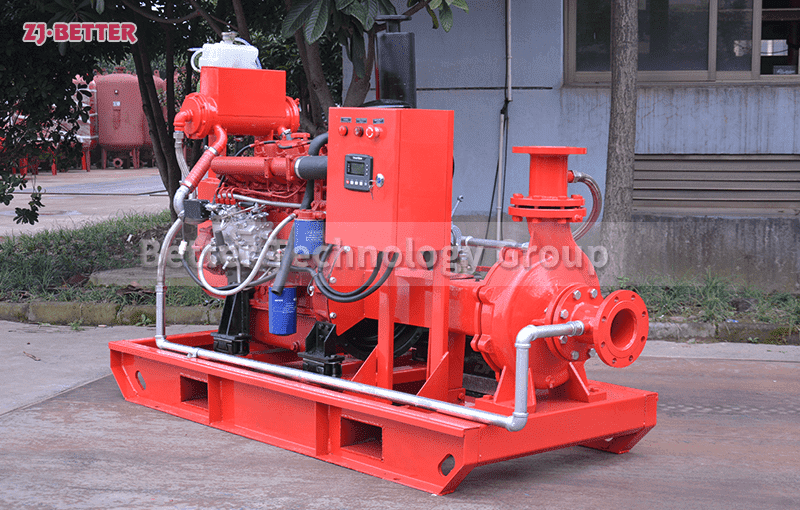

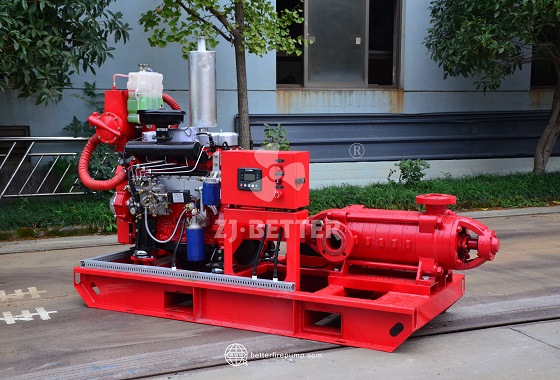

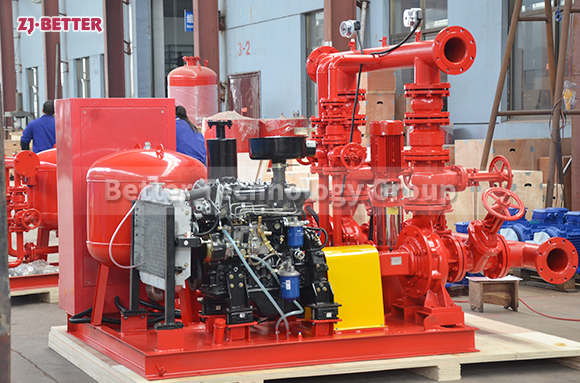

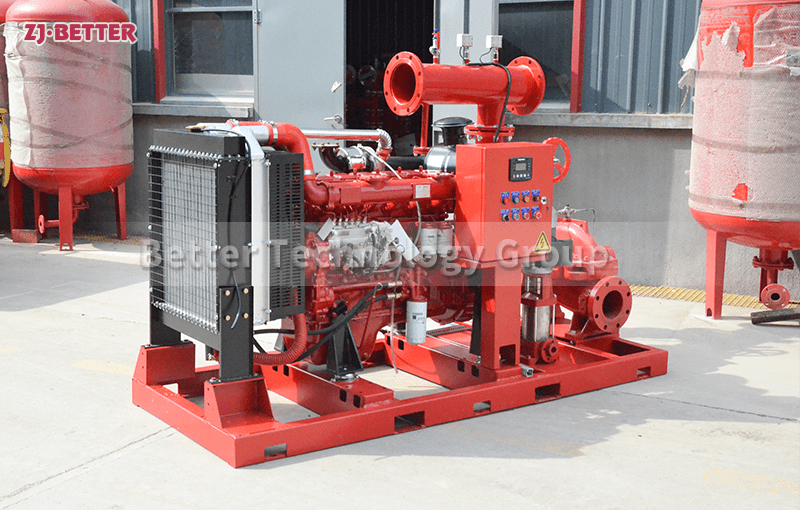

With a flow rate of 2000 gallons per minute and a pressure rating of 100 pounds per square inch, it provides an unprecedented volume of water to rapidly and effectively extinguish fires. With a robust diesel engine and top-grade components, it ensures uninterrupted operation, offering uncompromising protection for lives and property. Whether it’s industrial facilities or commercial complexes, this pump set exhibits outstanding versatility and can seamlessly integrate into existing fire protection systems, providing comprehensive fire safety coverage. Through optimized design, it maximizes water flow while minimizing energy consumption, ensuring efficient firefighting operations. Compliant with global fire safety standards, it delivers reliability and compliance, instilling confidence in fire departments, industrial facilities, and property owners, offering maximum protection for what matters most.

🚒 Unrivaled Firefighting Capacity: When it comes to extinguishing fires swiftly and effectively, the XBC-OTS is your ultimate ally. With a staggering flow rate of 2000 gallons per minute and a pressure rating of 100 pounds per square inch, it delivers an unprecedented volume of water to combat fires with unmatched force.

🔐 Unyielding Reliability: In the face of emergencies, dependability is paramount. The XBC-OTS Diesel Engine Fire Pump Set is engineered to withstand the toughest firefighting scenarios. Its robust diesel engine and top-grade components ensure uninterrupted operation, ensuring the protection of lives and properties without compromise.

🌐 Versatility Redefined: From industrial facilities to commercial complexes, the XBC-OTS Diesel Engine Fire Pump Set excels in versatility. It can seamlessly integrate into existing fire protection systems or serve as a standalone unit. Whatever the application, this pump set guarantees comprehensive fire safety coverage.

⚙️ Engineered for Optimal Performance: Efficiency is the key to effective fire suppression. The XBC-OTS Diesel Engine Fire Pump Set is optimized for peak performance. Its advanced design maximizes water flow while minimizing energy consumption, ensuring efficient firefighting operations. With intelligent control systems, monitoring and managing the pump set is effortless, enabling precise control and efficient resource allocation.