Diesel Fire Pump Set Ensures Continuous Water Supply for Large Facilities During Power Outages

Diesel-driven fire pump sets, independent of the power system, ensure continuous and stable fire water supply for large facilities during power outages, ensuring efficient firefighting emergency response.

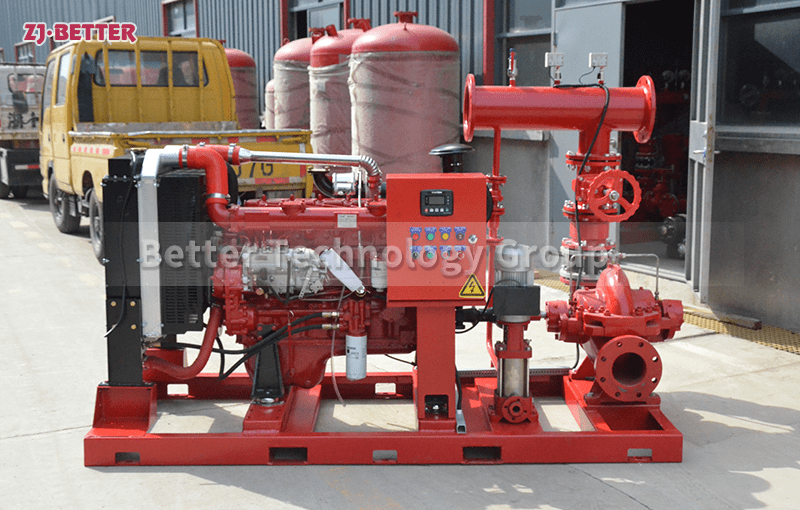

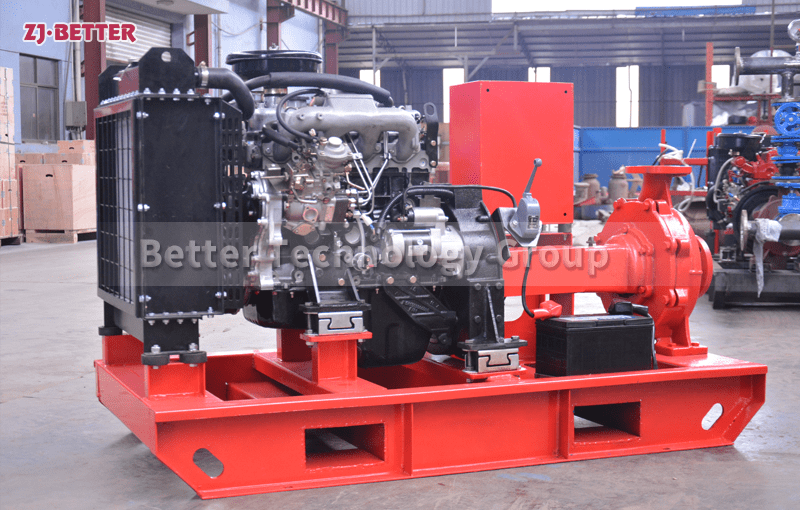

Diesel-driven fire pump sets are a key emergency fire water supply equipment, designed to meet the emergency fire fighting needs of high-risk places, especially suitable for places where power-off environments cannot rely on electric drive systems. With the acceleration of urbanization, the fire protection systems in large buildings, industrial parks, storage and logistics centers and other places have higher and higher requirements for the reliability of water supply, especially in the event of a fire, the timeliness and continuity of water supply are crucial to the fire fighting effect. The diesel-driven fire pump set drives the water pump through an independent diesel engine to ensure that it can still provide a stable and continuous water supply in the event of power outages or power grid failures, and to maximize the normal operation of the fire protection system in emergency situations. The equipment consists of a high-efficiency diesel engine, a fire water pump, a fuel tank, a cooling system, an exhaust silencer, an automatic control cabinet, etc. All components are highly integrated to ensure that it can operate stably in various extreme environments and provide stable water pressure and flow.

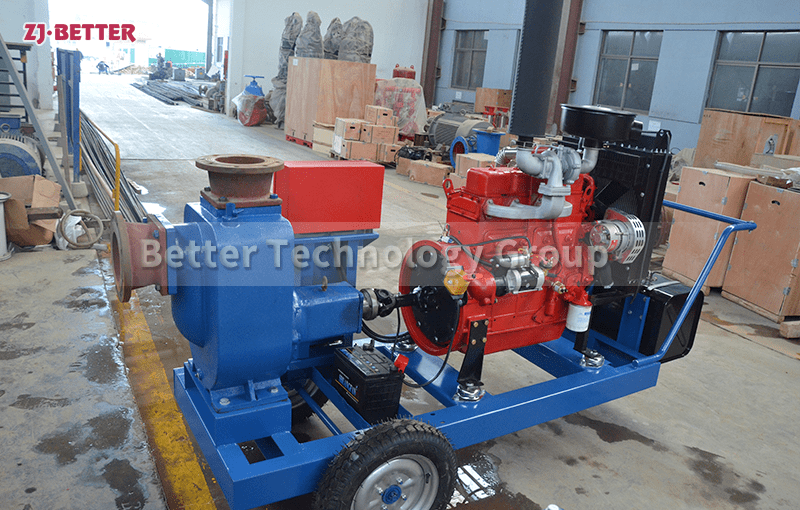

The main advantages of diesel-driven fire pump sets are their independence and high reliability. Unlike traditional electric fire pumps, diesel-driven systems do not rely on grid power, and can still start quickly in the event of power outages or grid fluctuations to provide continuous fire water supply. This feature makes diesel fire pumps the first choice for many important facilities, especially for those areas and projects that are overly dependent on electricity or have unstable power supply. The diesel engine has a fast starting speed and can quickly provide water flow at the beginning of the fire, ensuring that firefighters can extinguish the fire in time in the golden early stage of the fire and prevent the fire from spreading. In addition, the diesel engine has a strong power output and long-term high-load operation capacity, and can continuously supply water for many hours, ensuring that the firefighting work is carried out uninterruptedly for a long time.

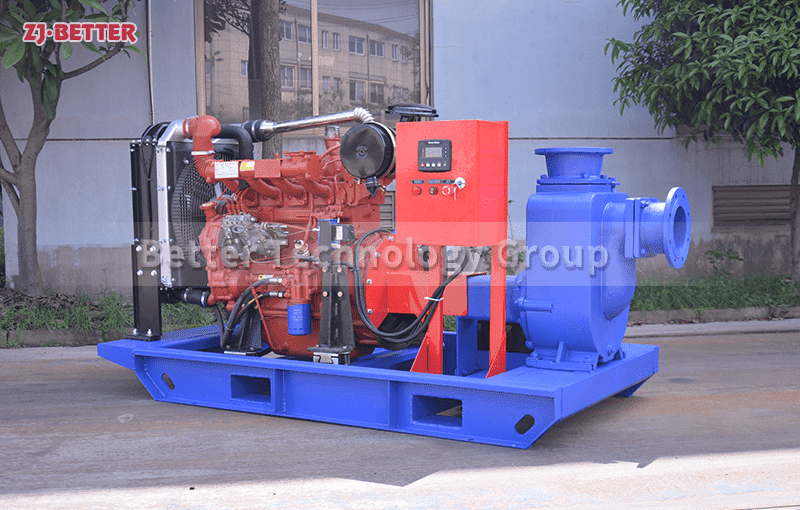

In terms of performance, the high-efficiency centrifugal pump equipped with the diesel-driven fire pump group can provide a large flow and high-lift water flow, ensuring that every part of the fire water system can obtain sufficient water pressure. The choice of multi-stage centrifugal pumps or single-stage centrifugal pumps enables the pump group to adapt to the needs of buildings and places of different sizes. For high-rise buildings or large-scale industrial parks, the pump group can provide sufficient water pressure to ensure that the water flow can reach the high floors of the building or the long-distance fire pipe network. The pump body is made of corrosion-resistant materials, and the impeller is made of high-strength cast iron or stainless steel, which ensures that the pump group has higher durability and wear resistance during long-term operation and extends the service life of the equipment. The impeller has undergone rigorous dynamic balancing testing to reduce vibration during operation and ensure stable operation of the equipment.

In addition, the cooling system equipped with the diesel-driven fire pump set can ensure that the diesel engine maintains an appropriate operating temperature when operating at high load. The cooling system of the pump set usually adopts an air-cooled or water-cooled design, which can efficiently remove the excess heat generated by the engine and prevent engine damage or system failure caused by overheating. The design of the diesel pump set also focuses on environmental adaptability, especially in high temperature, low temperature, humid or high altitude environments, the equipment can still maintain efficient operation. For places that need to be used under extreme weather conditions, the external protection system of the pump set can effectively prevent the damage of environmental factors such as dust, rain, and corrosive gases, ensuring the continuous operation of the equipment in harsh environments.

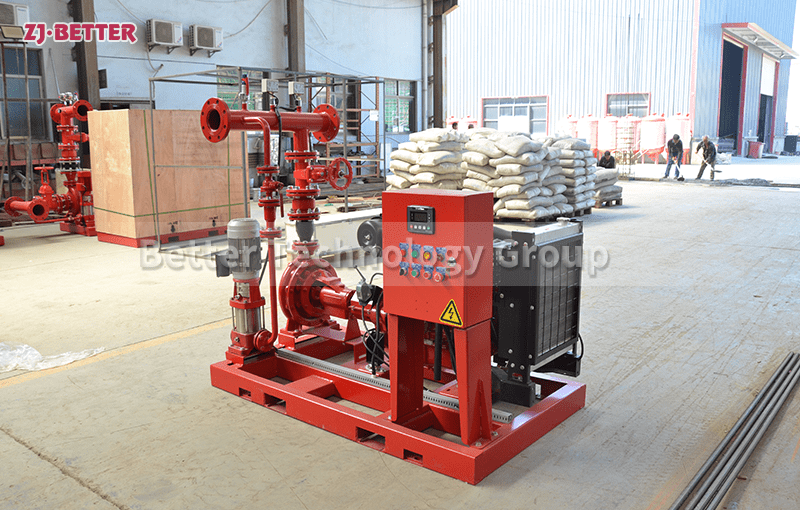

In terms of the control system, the diesel-driven fire pump set is equipped with an intelligent control cabinet, whose functions include automatic start, manual start, remote control, pressure monitoring, overload protection, etc. The intelligent design of the control system can monitor the working status of the pump set in real time, including parameters such as pump pressure, water temperature, current, voltage, etc., and transmit data in real time through sensors. If the system finds an abnormality, such as low oil pressure or high temperature, the control system will automatically sound an alarm and shut down for protection to prevent damage to the equipment. For places that require remote operation and monitoring, the control system of the pump group also supports remote control functions. Operators can start and stop the equipment, query the status and handle alarms through mobile phones, computers and other devices. This intelligent design makes the equipment more convenient and efficient, reduces manual intervention and improves emergency response capabilities.

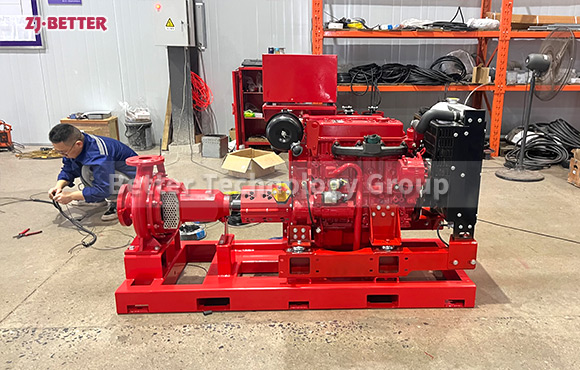

In terms of installation and maintenance, diesel-driven fire pump groups are also significantly convenient. The equipment is usually designed as an integrated structure, and all major components are installed on a solid base, which reduces the difficulty of connecting pipes and installation and commissioning between equipment. The base is equipped with lifting holes and lifting points for easy on-site handling and installation. The shell of the equipment is made of high-strength steel plate or aluminum alloy material, which has strong shock resistance and corrosion resistance and is suitable for use in various environments. For later maintenance, the design of diesel-driven fire pumps is also very user-friendly. All important maintenance parts, such as diesel engines, fuel tanks, cooling systems, etc. are easily accessible, and maintenance personnel can quickly complete daily inspections, cleaning and replacement work. The lubrication system of the pump group is also designed with automatic lubrication function, which reduces the frequency of manual lubrication and reduces maintenance costs.

The application range of diesel-driven fire pump group is very wide, especially suitable for places with strict requirements on fire water pressure and flow, such as high-rise buildings, petrochemical enterprises, airports, ports, oil fields, mines, etc. Whether in emergency response when a fire occurs or in the usual maintenance of the fire protection system, the diesel-driven fire pump group can provide efficient and reliable water supply to ensure the normal operation of the fire protection system. In fire protection work, the advantages of diesel-driven pumps are particularly obvious. It can ensure that the entire system can still operate in the absence of power support and ensure that the fire fighting work is not affected by water supply interruption.

In summary, the diesel-driven fire pump group has become an indispensable and important part of the modern fire protection system with its strong independence, reliable performance, intelligent control system and convenient maintenance design. It provides a stable and continuous fire water source guarantee for high-risk places such as large buildings and industrial parks, ensuring that the fire protection system can still work efficiently and stably in the event of power outages or other emergencies. With the acceleration of industrialization and urbanization, the demand for diesel-driven fire pump sets will continue to grow and become an important equipment in the global fire protection industry.