Built to Last, Engineered for Safety: A Comprehensive Guide to Industrial Diesel Split Case Fire Pump Systems

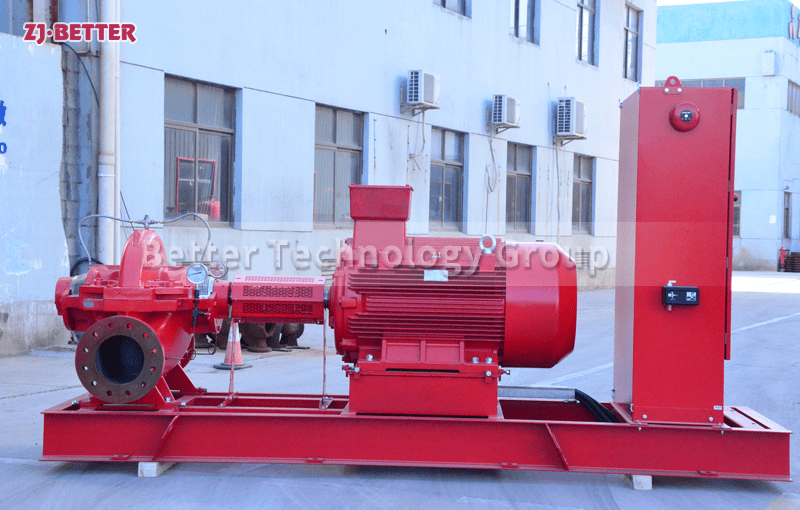

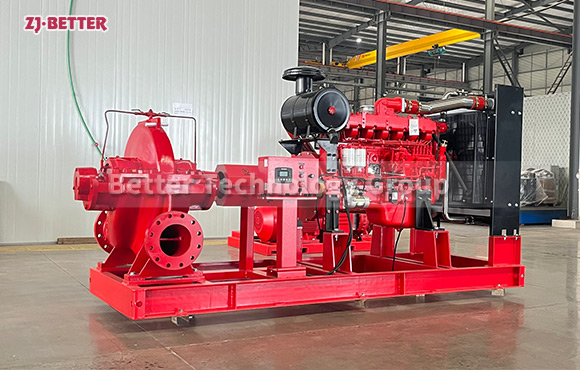

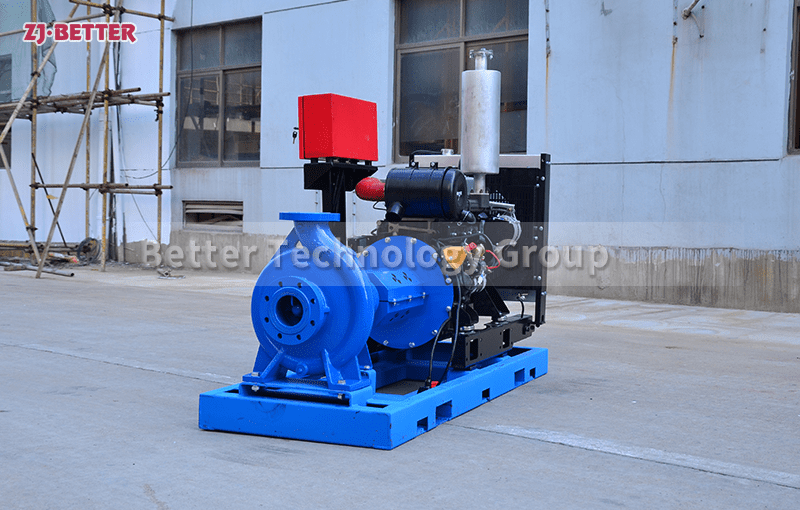

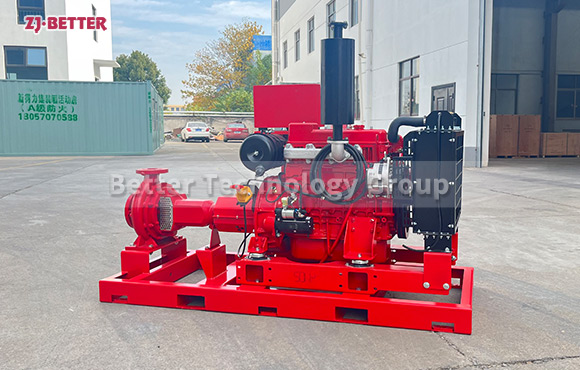

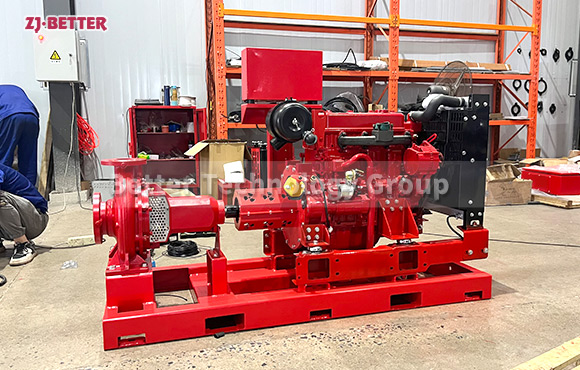

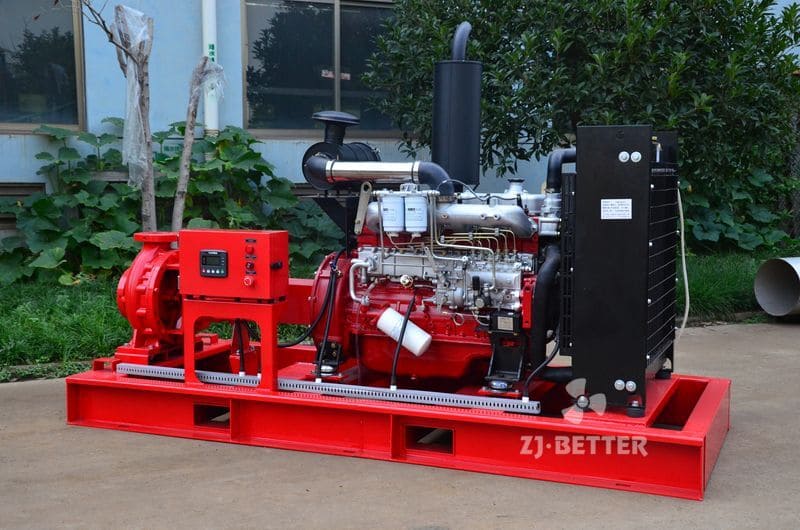

In today’s industrial and large-scale building fire protection systems, a reliable fire pump is the cornerstone of safety. The industrial-grade diesel-driven horizontal split case fire pump system is engineered to meet the demands of high-intensity and high-standard scenarios. With a compact split-case design powered by a high-performance diesel engine, it ensures fast startup and stable operation under critical conditions.

Its robust and durable pump body is built to withstand high-pressure operation for extended periods, making it ideal for emergency fire suppression. The double suction impeller significantly improves hydraulic efficiency and delivers a steady high-volume water supply. The diesel drive eliminates concerns over unstable power supply or outages, making this unit a dependable solution in petrochemical plants, power stations, and large logistics hubs.

Equipped with an intelligent control panel, the system supports automatic start/stop, fault alerts, and remote monitoring, ensuring enhanced operational safety. Pre-assembled and tested before delivery, the unit is easy to install and maintain—an essential component in any modern fire protection strategy.

This enterprise specializes in the research, development, and manufacturing of fire pump systems, consistently delivering efficient and reliable fire protection solutions to users worldwide. Its product portfolio includes diesel fire pumps, electric fire pumps, pressure stabilization systems, control cabinets, and more—serving key industries such as industrial manufacturing, commercial facilities, energy, transportation, and petrochemicals. Backed by a rigorous quality management system, the company integrates advanced production technologies and testing equipment to ensure each unit meets international standards for performance, safety, and durability. Through continuous innovation and tailored design capabilities, the company has earned a strong reputation in the field of fire safety.