How to properly maintain the diesel fire pump?

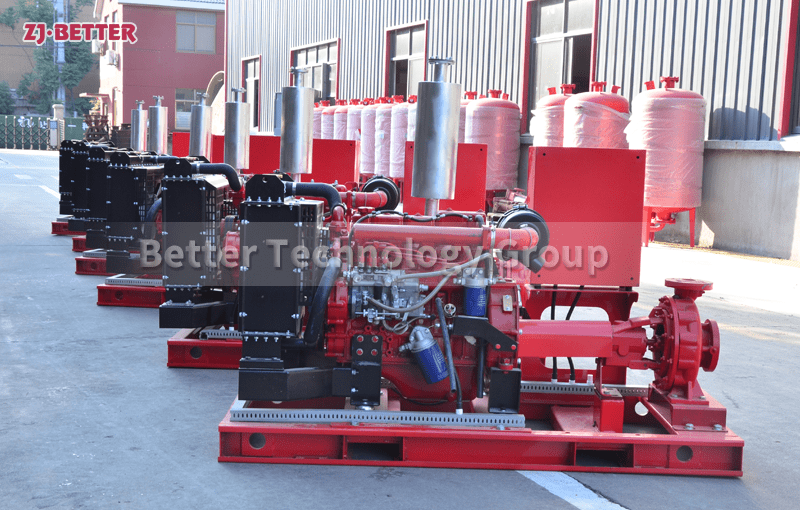

The biggest difference between the diesel engine fire pump and the electric water pump is that it has its own independent power supply system – battery. Therefore, the startup and operation of the diesel engine fire pump can be completely separated from the mains.

The diesel engine fire pump is usually used as a backup facility, and it will automatically start only when the fire signal comes, the electric water pump fails or the power is cut off. When equipped with an ultra-low pressure pump starting device, the matching electric pump control cabinet should also be equipped with an ultra-low pressure pump starting device, and the lower limit of the pump starting should have a certain pressure difference. Of course, it is also possible to design a control system that is more suitable for customer needs according to customer requirements.

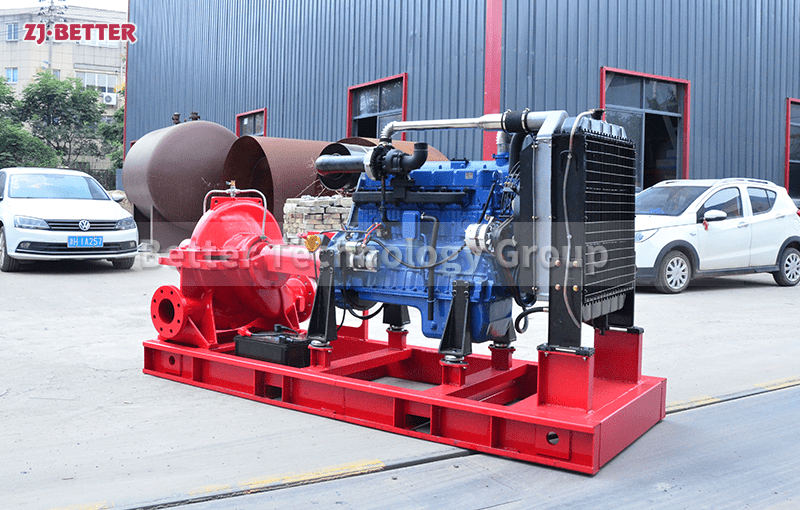

Proper maintenance of diesel fire pumps, especially preventive maintenance, is simple and economical maintenance, and therefore the key to extending service life and reducing operating costs. For routine maintenance, check the fuel level of the fuel tank by following the steps below – observe the fuel level in the fuel tank and add it as needed.

1. Check the oil level in the oil pan to see if the oil level reaches the mark on the oil dipstick. When insufficient, it should be added to the specified amount, but should not exceed the upper limit of the scale mark.

2. Check the oil level of the diesel engine fire pump governor, if it does not meet the specified mark, add enough oil.

3. Check whether there is enough grease at the filling point of the diesel engine fire pump water pump. Remove the grease nipple on the diesel engine circulating water pump and observe whether there is enough grease in it. If not, inject enough grease with a grease gun.

4. Check whether the water in the tank is sufficient. If you find that the water in the water tank is insufficient, replenish it in time. The added water should be clean fresh water such as tap water or clean river water. Direct use of groundwater will easily form scale in the water tank, which will affect the cooling effect and cause malfunctions. Therefore, groundwater can only be used after it has softened.

5. Check the three leaks (water, oil, gas) – check the sealing surfaces at the joints of the oil pipes and water pipes, if there is leakage, it should be solved immediately; if the supercharger at the exhaust pipe and cylinder head gasket is loose or Air leakage should also be eliminated in time.

6. Check the installation of the accessories of the diesel engine, including the installation stability of the accessories, the firmness of the anchor bolts and their connection with the working machine.

7. Check the drive connecting plate of the fuel injection pump of the diesel engine fire pump – check whether the connecting screw is loose. If it is loose, re-correct the fuel injection advance angle and tighten the connecting screw.

8. Clean the appearance of the diesel engine and auxiliary equipment, wipe the oil stains, water and dust on the surface of the fuselage, turbocharger, cylinder head cover and air filter with a dry cloth or a rag soaked in diesel oil.