Weather-Resistant Diesel Fire Pumps: Power Systems Built for Harsh Outdoor Environments

The ZJ-BETTER weather-resistant diesel fire pump is built for extreme environments, featuring IP55 protection, automatic start, remote monitoring, and reliable water supply. Ideal for petrochemical, mining, and tunnel applications, fully compliant with NFPA20 and global fire safety standards.

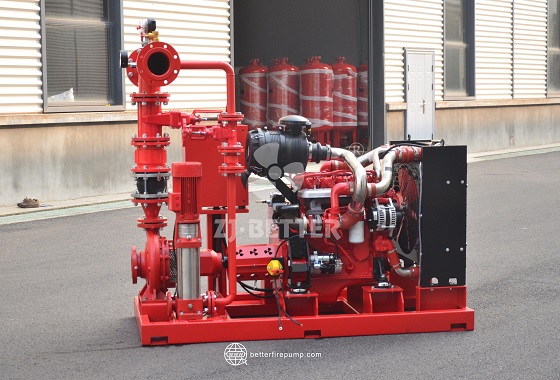

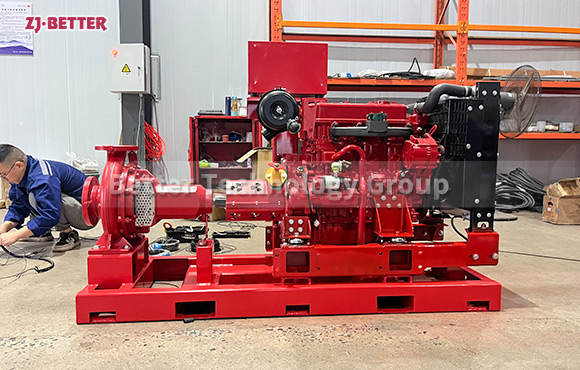

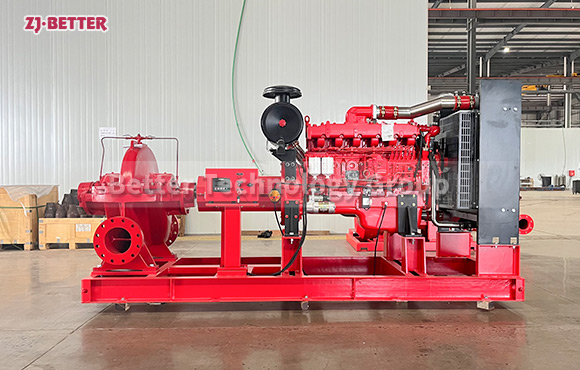

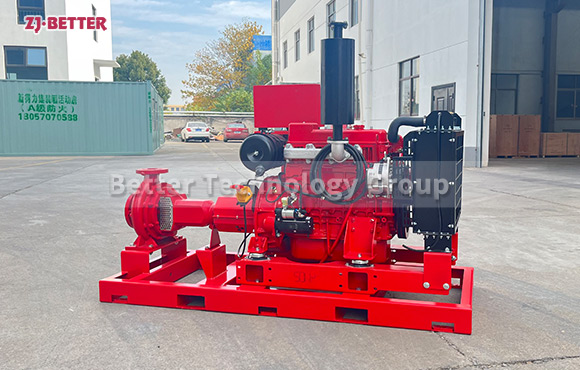

In today’s growing demand for reliable fire protection in industrial safety and public infrastructure, weather-resistant diesel fire pumps stand out as essential equipment for ensuring continuous water supply in emergency scenarios. ZJ-BETTER, a globally recognized manufacturer of fire pumps, has developed this outdoor diesel pump system specifically to operate in extreme and challenging environments. Designed for chemical plants, mining sites, power stations, marine docks, and tunnel projects, this diesel pump system combines compact construction, corrosion-resistant coating, automatic start, remote monitoring, and high-efficiency fuel management into one highly dependable unit. Utilizing internationally renowned diesel engines paired with end-suction centrifugal pumps, the system ensures consistent operation even during power outages, severe climate conditions, or high-impact environmental changes. The structure is engineered with an IP55 or higher protection rating and treated with anti-corrosion powder coating to resist prolonged exposure to rain, humidity, UV radiation, sandstorms, and snow, significantly extending its service life while reducing maintenance needs. Its intelligent control panel enables automatic monitoring, fault detection, auto-switching, and remote linkage, ensuring the unit starts within 15 seconds of receiving a fire signal. A dual fuel tank configuration and real-time fuel level sensors allow uninterrupted operation for extended periods, ideal for large-scale applications. Moreover, ZJ-BETTER offers region-specific versions of this fire pump, including high-altitude, high-temperature, and explosion-proof models, to accommodate harsh environments such as the Middle East, Africa, Southeast Asia, and Northern Europe. The integrated chassis design allows for plug-and-play installation—factory pre-tested, pre-wired, and pre-configured—resulting in dramatically reduced installation times and costs. Its compact size also supports containerized transport and modular deployment in remote, unmanned sites. From a performance perspective, this diesel pump can maintain stable water pressure for over 8 hours under full load and complies fully with NFPA20, GB27898, and EN12845 standards. Combined with ZJ-BETTER’s proprietary cloud-based monitoring system, users can access real-time operating data, alarm history, fuel analytics, and maintenance reports via desktop or mobile app, bringing intelligent and visible equipment management to the forefront. With its fuel-saving engine, intelligent idle control, and low-noise standby mode, this diesel pump contributes to eco-friendly fire safety infrastructure. Whether in alpine mines, coastal ports, deserts, or frozen territories, ZJ-BETTER’s weather-resistant diesel fire pump delivers unmatched reliability, quick response, and easy maintenance. With successful deployments in hundreds of international projects, this system has proven its value not just in firefighting performance but also in resisting corrosion, high temperatures, mechanical shocks, and freezing conditions. As ZJ-BETTER continues to drive innovation and quality, it remains a trusted force in protecting critical infrastructure around the world.