Safety Meets Efficiency: The Value of Diesel Fire Pumps in Industrial and Commercial Settings

Explore the safety and efficiency of ZJ-BETTER diesel fire pumps designed for industrial and commercial use. Ensure continuous fire protection in power outages and harsh environments with high-performance, customizable solutions.

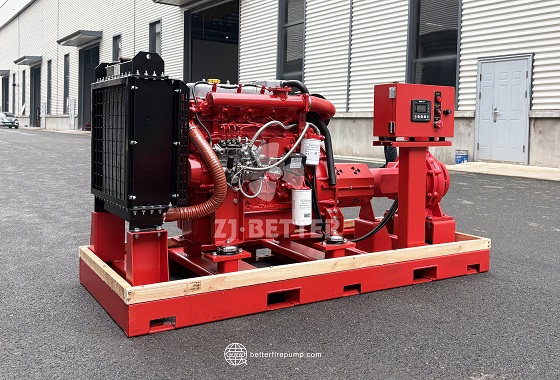

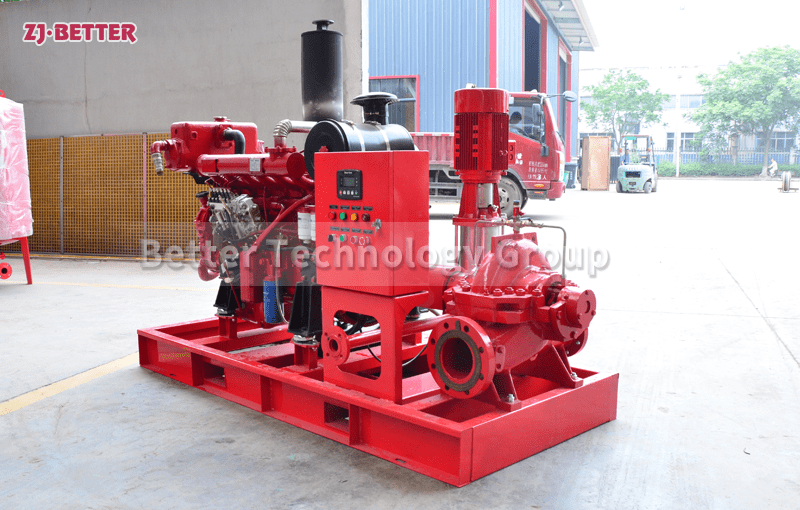

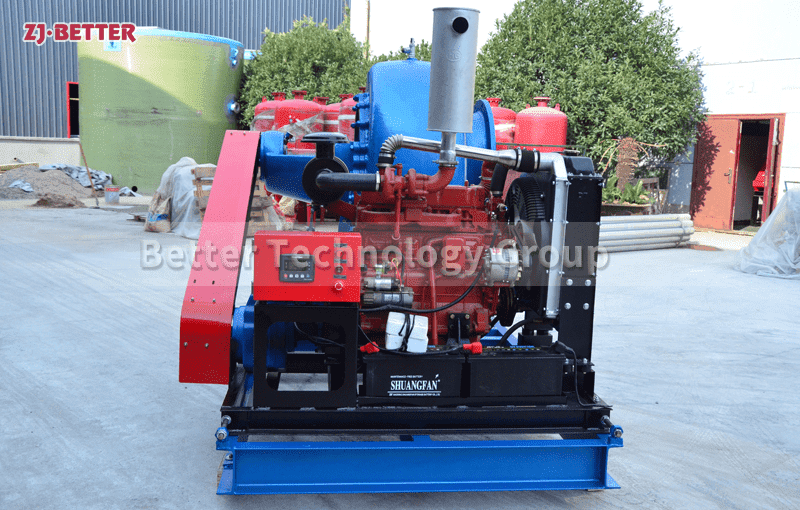

In today’s increasingly complex and high-density modern industrial and commercial buildings, fire safety has become an indispensable component of business operations. As a critical firefighting water supply system, the reliability and high-performance capabilities of diesel fire pumps directly impact the safety of personnel and property in emergency scenarios. In high-risk environments such as petrochemical plants, power plants, warehousing and logistics facilities, large commercial complexes, and industrial manufacturing zones, a disruption in the conventional power supply system traditional electric pump systems risk failure. In contrast, diesel-driven fire pumps leverage their unique self-powered advantage to ensure rapid startup and continuous water supply even under adverse conditions such as power outages, explosions, high temperatures, humidity, or areas distant from power sources, thereby establishing an impenetrable fire safety barrier. The ZJ-BETTER brand diesel fire pump system features high-quality engines and an integrated control cabinet design, ensuring operational stability through dual mechanical and electrical redundancy. Upon receiving a fire signal, it can automatically activate water supply within a short timeframe, significantly enhancing response efficiency and fire extinguishing speed. Its modular structure and reinforced base design not only improve installation convenience but also greatly enhance seismic resistance in special environments such as earthquakes and high wind pressures. Additionally, the system can be customized to different head and flow rates based on the user’s on-site conditions, meeting fire protection water pressure and water supply requirements across multiple scenarios and building types, truly achieving “customized configuration and precise water supply.” In terms of energy consumption control, the intelligent control panel配套 for the diesel fire pump can monitor operational parameters such as speed, pressure, oil temperature, water temperature, and fuel level in real time, ensuring efficient operation while reasonably controlling fuel consumption and reducing maintenance costs. Additionally, through the RS485 communication interface, it achieves seamless integration with building fire protection systems, offering multiple functions such as remote alarms, interlocking control, automatic detection, and regular testing, thereby enhancing the system’s automation and intelligence levels. In terms of service life and maintenance, the ZJ-BETTER diesel fire pump’s pump body is made of high-strength cast iron with a surface powder coating for corrosion resistance, capable of withstanding high pressure and impacts, and maintaining stable performance even after prolonged operation. All components of the pump assembly are designed and manufactured in accordance with international and domestic standards such as NFPA 20 and GB 27898, ensuring controllable quality, strong interchangeability, simple maintenance, and ample spare parts availability. In global applications, this system has been deployed in major projects such as large oil fields in the Middle East, port logistics in Southeast Asia, copper mines in South America, power plants in West Africa, and railway engineering projects in Europe. It has gained widespread recognition and trust from users due to its robust product performance and reliable operational reputation. Especially in the context of global energy transition, diesel fire pumps, as independent energy-based fire protection solutions, are increasingly becoming the preferred standard configuration for multinational corporations and government engineering projects. Looking ahead, as concepts like smart buildings, green industry, and digitalized maintenance become more widespread, the digitalization, visualization, and remote management of diesel fire pump systems will be key areas of evolution. The ZJ-BETTER brand has already taken the lead in this area, launching smart diesel pump stations with IoT connectivity and cloud-based management capabilities to provide global users with more efficient, intelligent, and safe fire protection solutions. In summary, diesel fire pumps are not merely emergency equipment in industrial and commercial settings but also the core power source of safety systems, combining stability, efficiency, and autonomy to form the solid foundation of industrial-grade fire safety solutions. Choosing ZJ-BETTER means choosing a commitment to safety for the future.