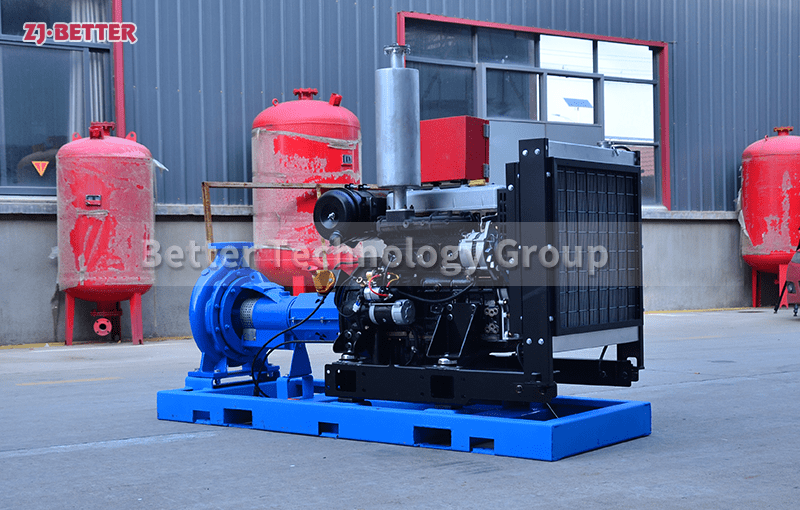

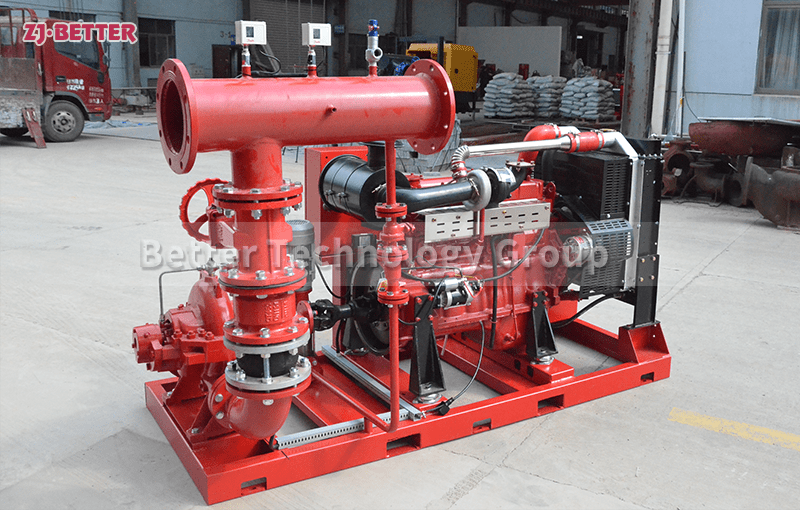

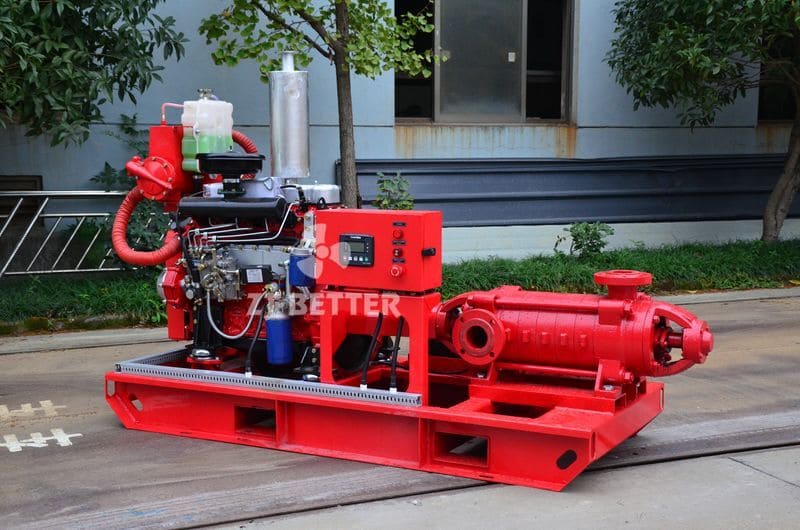

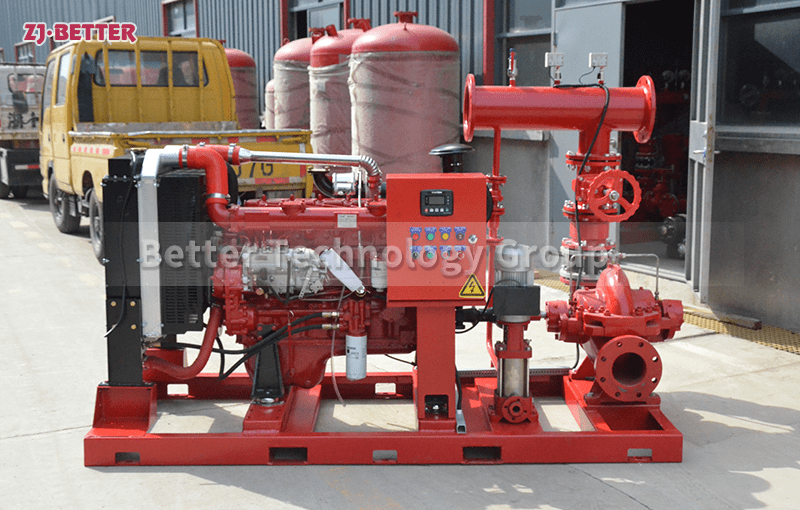

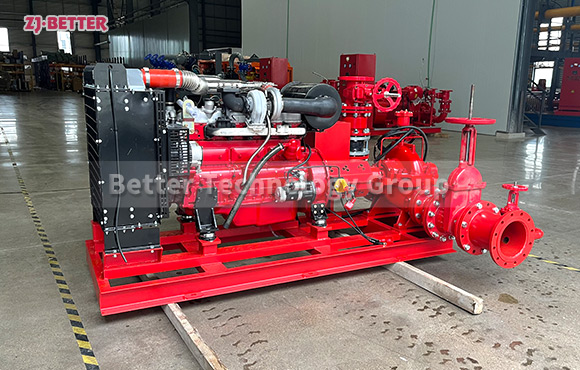

Our fire pump is renowned for its outstanding performance and reliability, specifically designed to respond to fire emergencies efficiently. It can start quickly in critical situations, ensuring a stable and efficient water supply. Whether in commercial buildings, industrial facilities, or public places, our fire pump delivers powerful performance and high head, swiftly transporting water to designated areas to ensure efficient firefighting operations.

The product features advanced hydraulic design and an energy-efficient motor, which not only ensures smooth operation but also effectively reduces energy consumption and operating costs. Its low-noise characteristic makes it particularly suitable for environments with strict noise control requirements, maintaining quiet and reliable operation even during 24/7 use. High-quality materials and meticulous manufacturing processes provide excellent durability, enabling the pump to work stably for long periods in high-temperature, high-pressure, and corrosive environments.

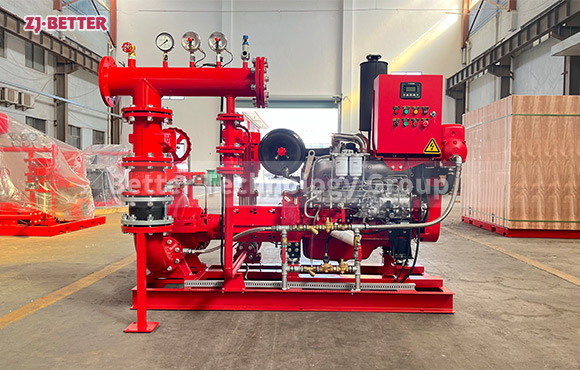

Equipped with an intelligent control system, the fire pump offers real-time monitoring, remote control, and fault alarm functions. Through a high-definition display, operators can easily monitor the operational status and quickly access parameters such as flow rate, pressure, and temperature. The built-in alarm system promptly issues warnings in case of abnormal operation, minimizing safety risks. The user-friendly maintenance design makes routine servicing simpler, prolonging the pump’s lifespan.

We are committed to providing customers with reliable fire pump solutions, combining superior performance with user-friendly design to ensure comprehensive fire safety. Whether for new construction projects or equipment upgrades, our products are always your top choice.

.jpg)