Advantages of hand-held diesel fire pumps

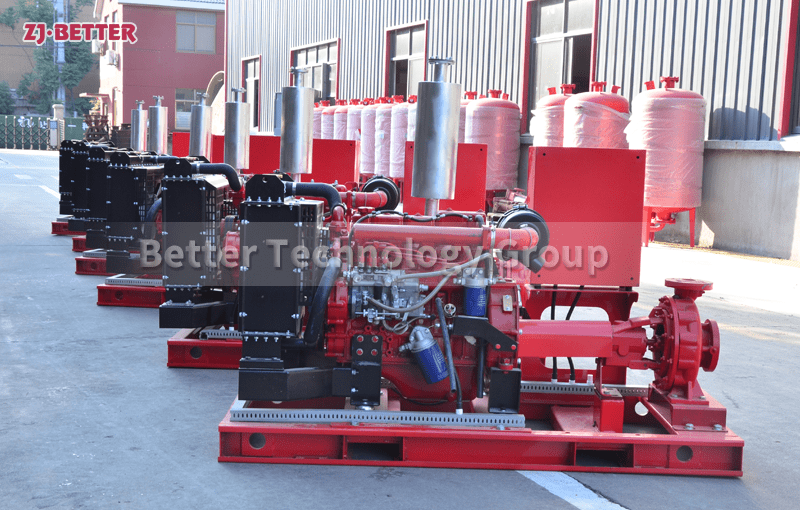

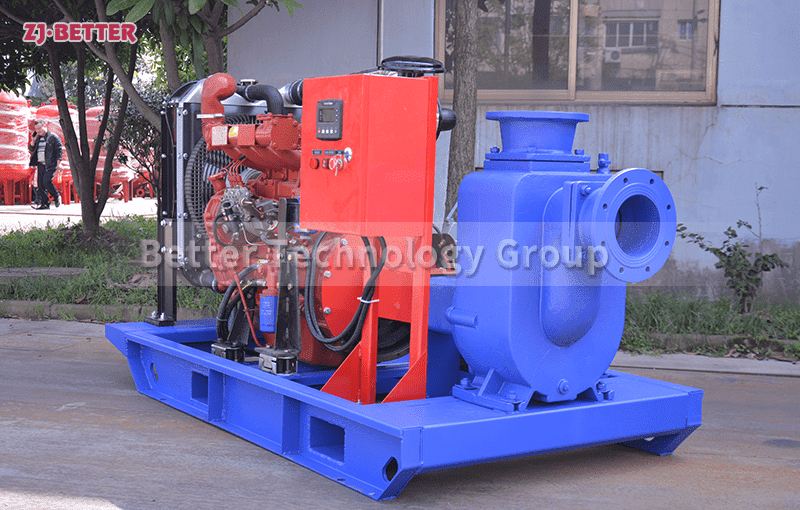

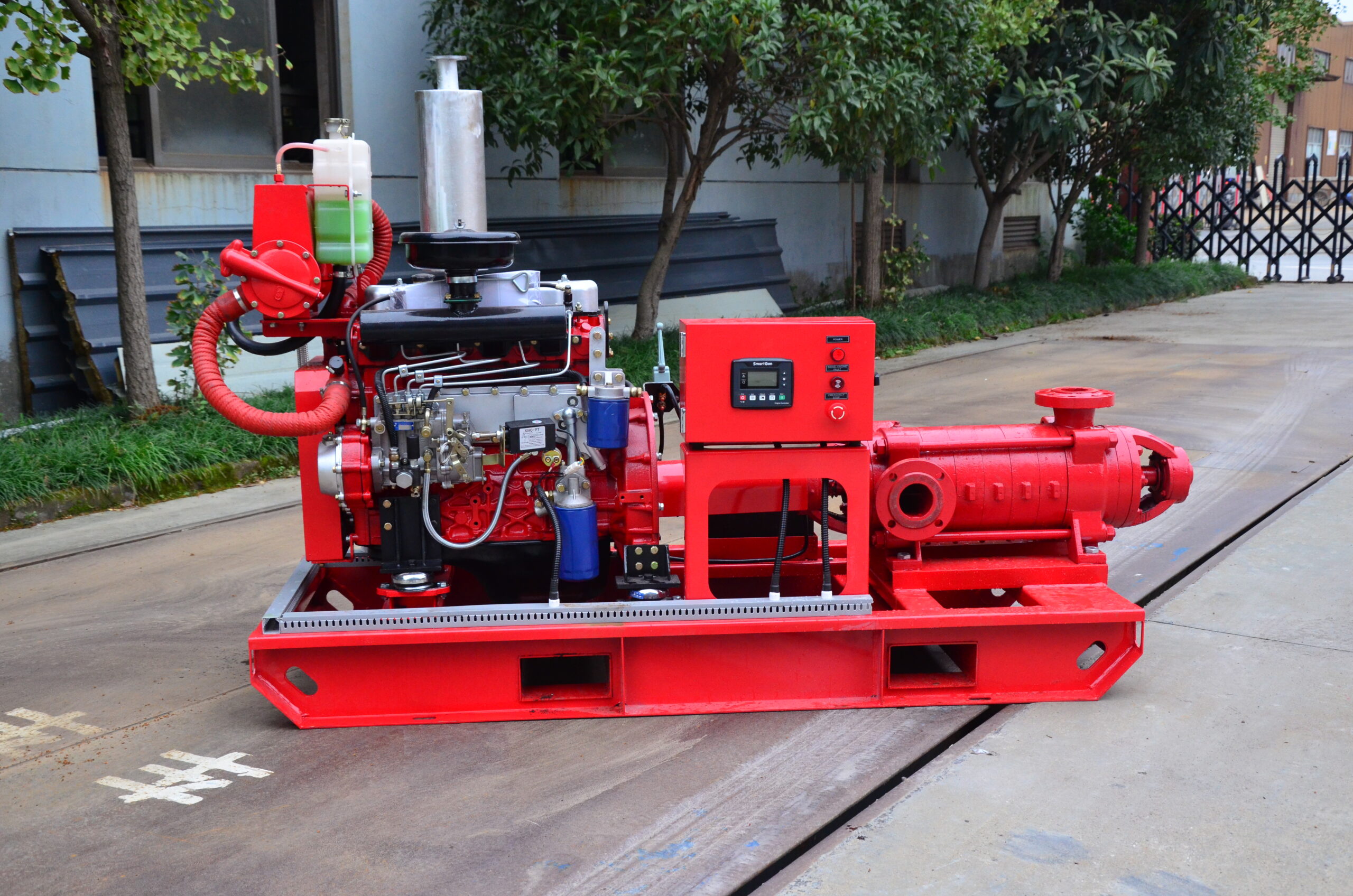

The hand-held fire pump is mainly suitable for the fire fighting of the armed police fire brigade, various professional fire brigades, industrial and mining enterprises, counties, villages and towns, etc. It is more specific in areas where fire vehicles cannot pass. , water supply and emergency disaster rescue ideal equipment.

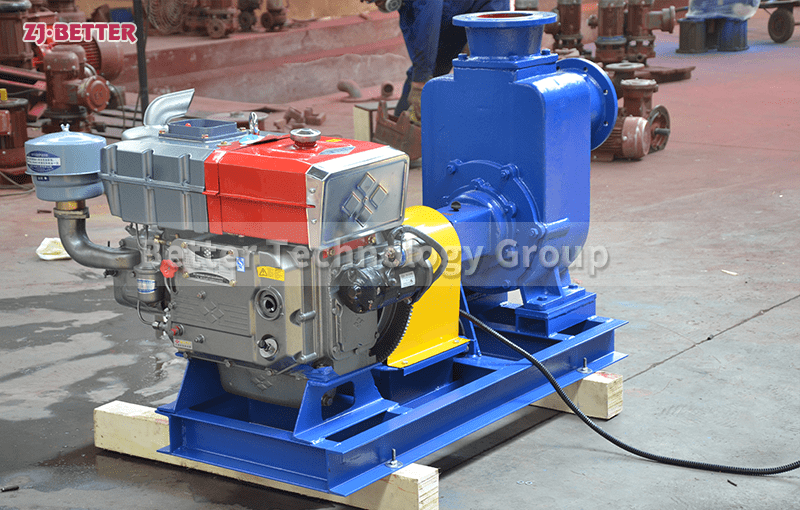

There is a liquid storage chamber in the body of the diesel engine water pump, which is the same as the pump working chamber through the upper return hole and the lower circulation hole, forming the axial return and external mixing system of the pump. After the pump stops working, the inner cavity of the pump has stored a certain volume. When the pump starts, the liquid stored in the pump is thrown upwards with the air under the action of the impeller, the liquid flows back to the working chamber through the grid of the gas-liquid separation pipe, and the gas is discharged out of the pump, making the pump A certain degree of vacuum is formed inside to achieve the effect of self-priming. The diesel engine water pump integrates self-priming and non-clogging sewage discharge. It adopts the axial backflow external mixing type, and through the unique design of the pump body and impeller flow channel, it can be installed without the bottom valve and tank water diversion like ordinary self-priming clean water pumps. It can also absorb and discharge liquids containing large solid particles and long fiber impurities, and can be widely used in municipal sewage discharge, flood control, drought relief, farmland irrigation in mountainous areas, and river pumping. It is an ideal diesel engine self-priming pump.