In modern firefighting systems across industrial, commercial, and municipal applications, ensuring a stable and immediate water supply under complex and unpredictable site conditions is a critical design priority. The diesel engine-driven fire pump is engineered precisely to address such scenarios, providing a reliable emergency water supply solution when electrical power is unavailable or unstable.

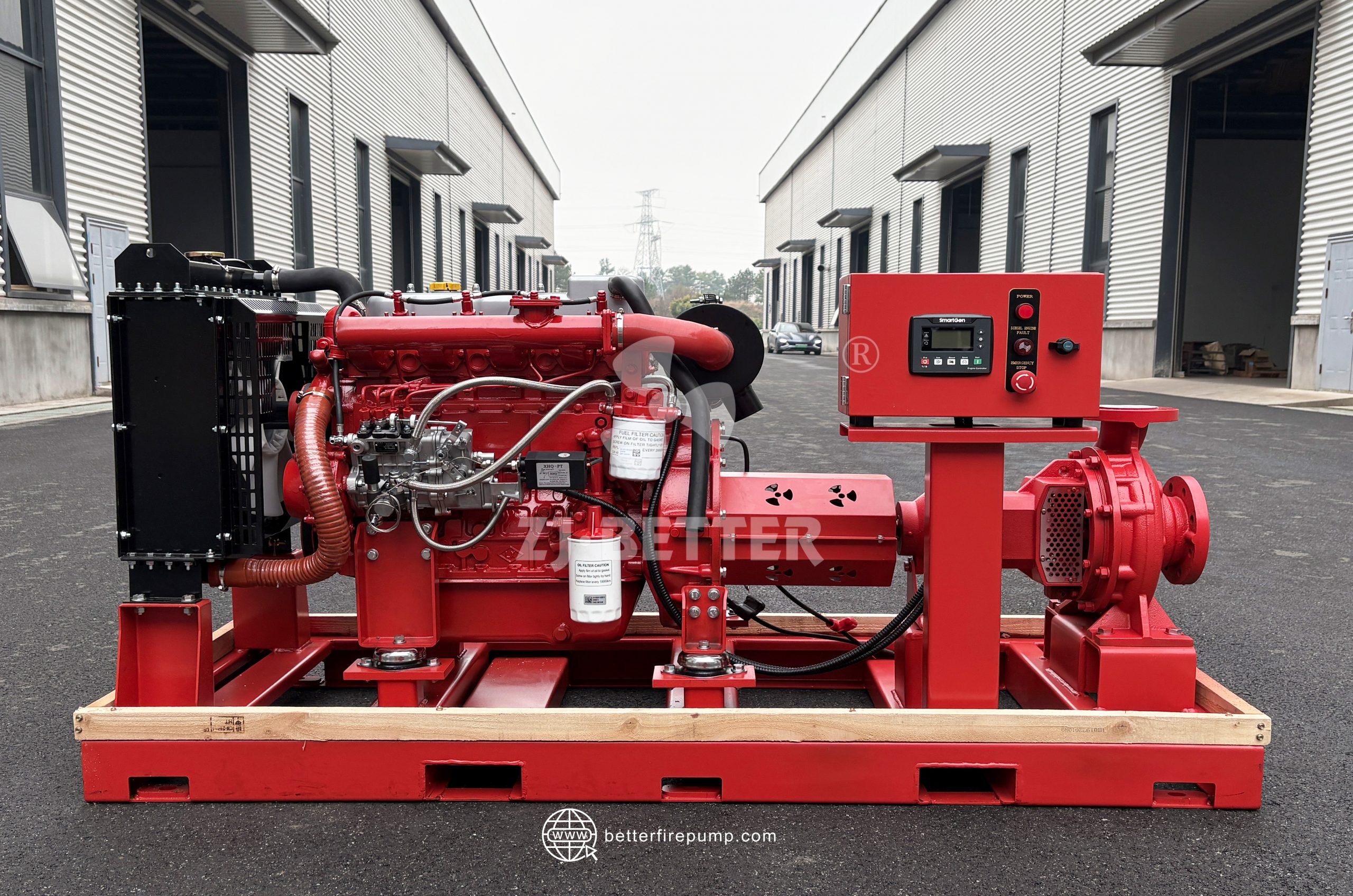

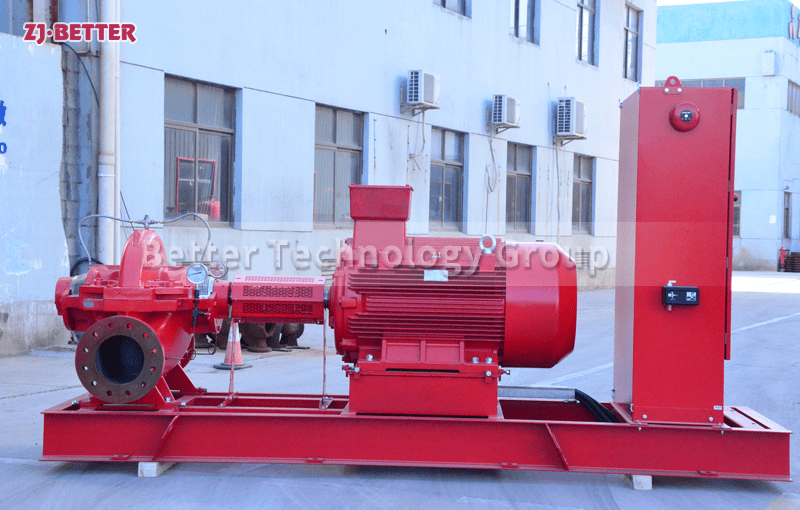

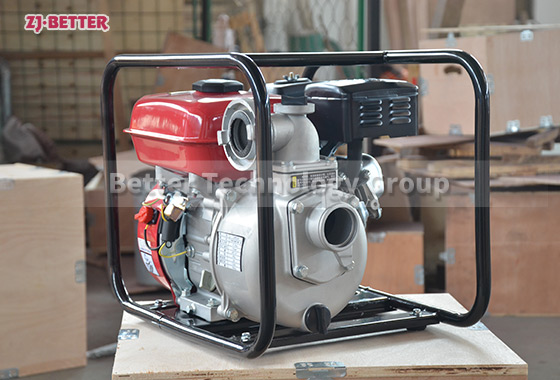

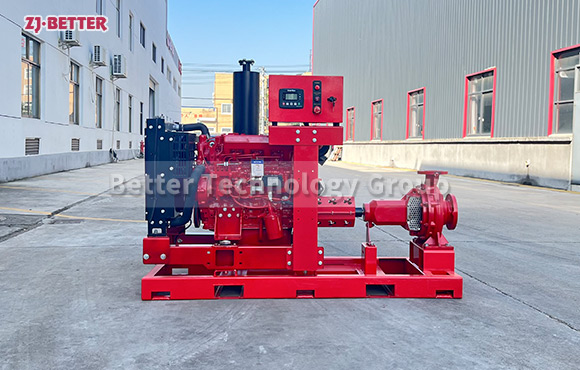

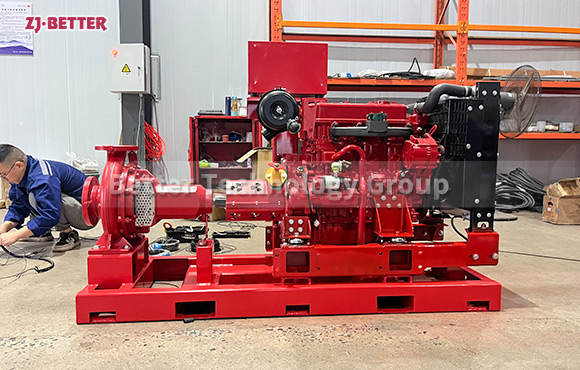

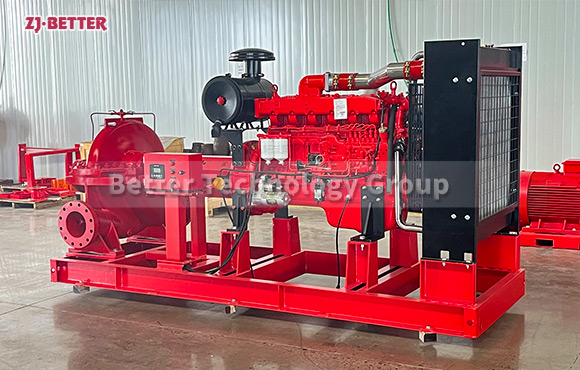

This type of fire pump uses a high-performance diesel engine as its power source, enabling operation entirely independent of the electrical grid. It is designed to start and run under extreme environmental conditions, such as blackouts, outdoor field installations, and harsh climates, offering superior redundancy and reliability to the fire protection system. Equipped with efficient self-priming or end-suction centrifugal pump structures, the system delivers fast startup, high flow output, and stable performance to ensure the fire response begins without delay.

Modern diesel fire pump units come integrated with intelligent control panels and automated systems, supporting remote monitoring, automatic starting, low oil pressure alarms, coolant temperature detection, and more. These functions enable real-time linkage with central fire control platforms, significantly enhancing the system’s automation level and emergency responsiveness. With a compact footprint and modular design, the system is easy to install and maintain, making it ideal for a wide range of environments such as industrial parks, petrochemical terminals, storage logistics centers, high-rise buildings, and urban secondary water supply systems.

Our diesel fire pumps are built in compliance with international standards such as CE, UL, and FM. They are available in various configurations to suit diverse project needs—material options include ductile iron, bronze alloy, and stainless steel, with customizable features such as manual/automatic startup, water-cooled or air-cooled engine types. Every unit undergoes rigorous factory testing to ensure optimal performance in high temperature, high humidity, high head, and large-flow conditions.

In summary, diesel engine-driven fire pumps are essential components in any robust fire protection system. With unmatched independence, reliability, and smart control capabilities, they are the trusted solution for emergency water supply assurance across all challenging environments.