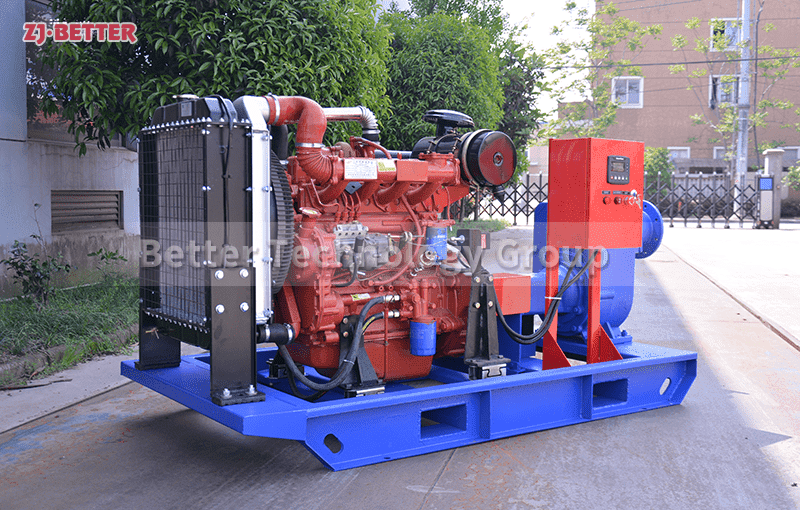

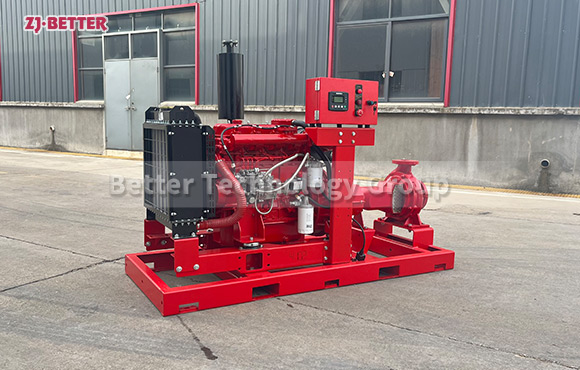

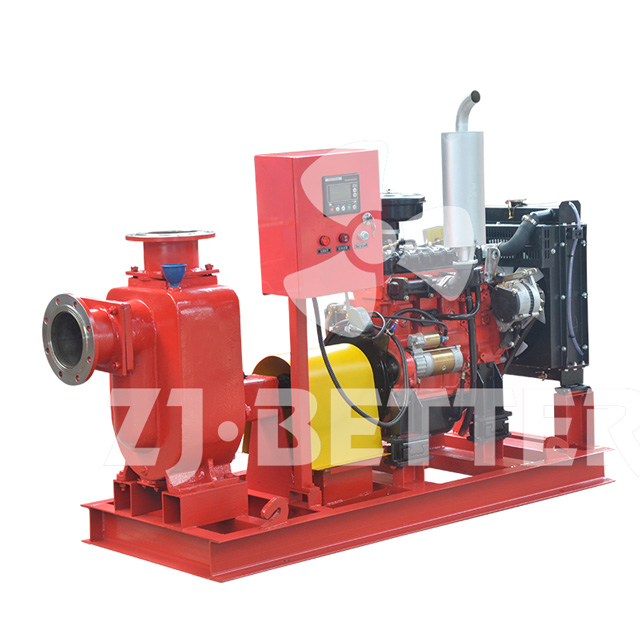

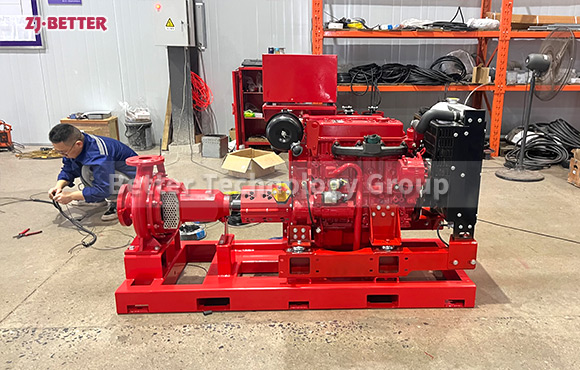

Diesel engine fire pump with control system

Diesel engine fire pump can be used in fire water supply in warehouses, docks, airports and other occasions. We usually choose the appropriate diesel engine fire pump model and application according to the head, flow, power, medium properties, and required materials provided by the user. In order to avoid mistakes, the loss caused by the installation environment will be comprehensively considered to ensure stable and reliable efficiency.

Diesel engine fire pump is a good water supply equipment, which is widely used in both ordinary water supply and fire water supply. As long as the appropriate model is selected to match the application, and the inspection and maintenance work is done well, the diesel engine fire pump will basically not fail. The diesel engine fire pump is highly automated, and can be equipped with different operating systems according to the needs of use. It has strong overload capacity, convenient maintenance and good starting characteristics. Since there are so many advantages in use, the daily inspection and maintenance work should be more meticulous. The daily maintenance of the diesel engine fire pump must check the fuel tank, battery, transmission connecting plate, connecting screws, check the three leaks (water, oil, gas) – check the sealing surface of the oil pipe and the water pipe joint, etc.