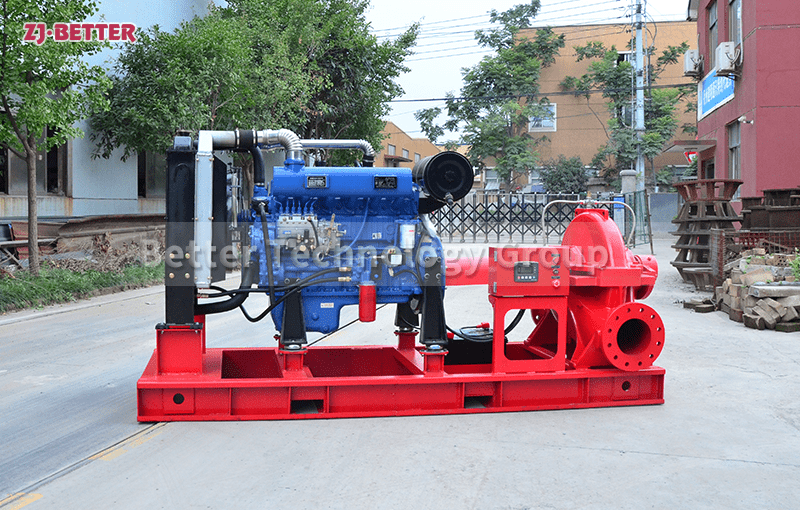

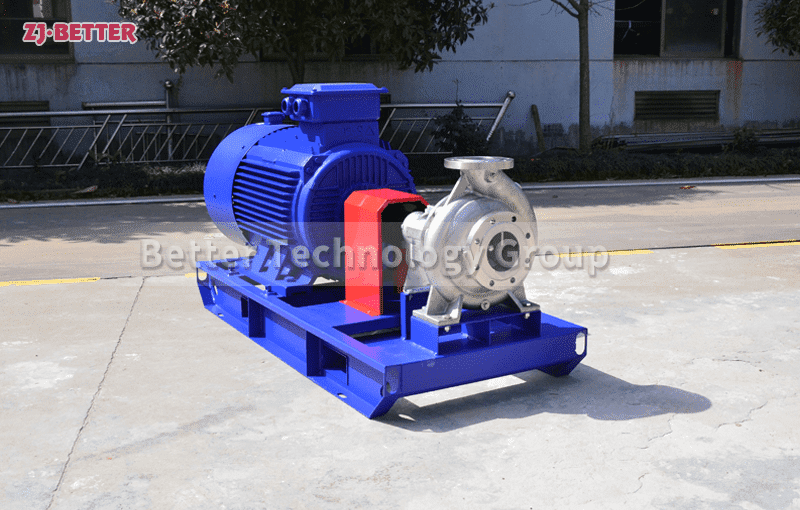

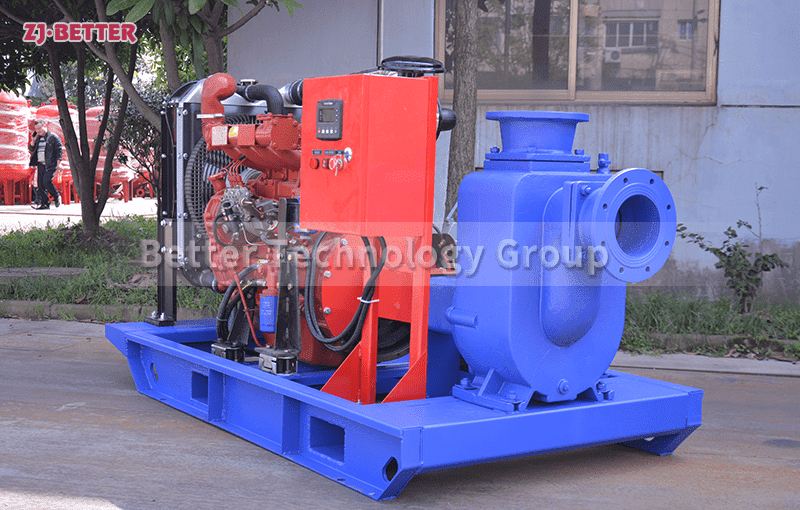

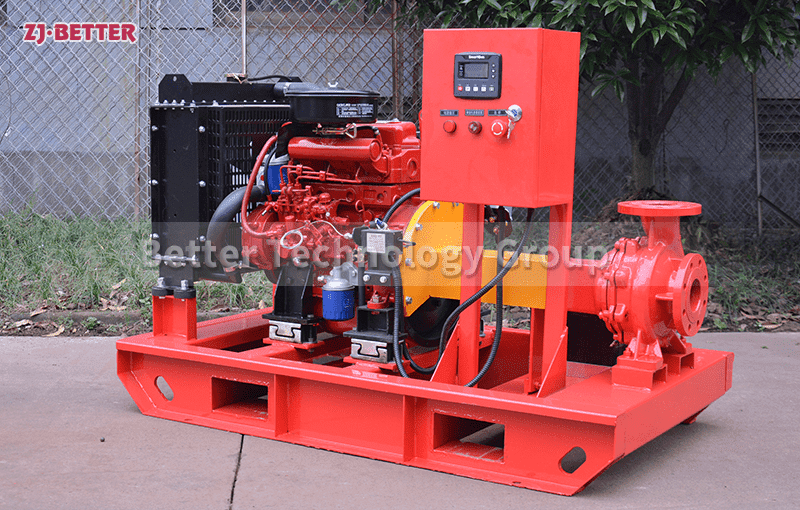

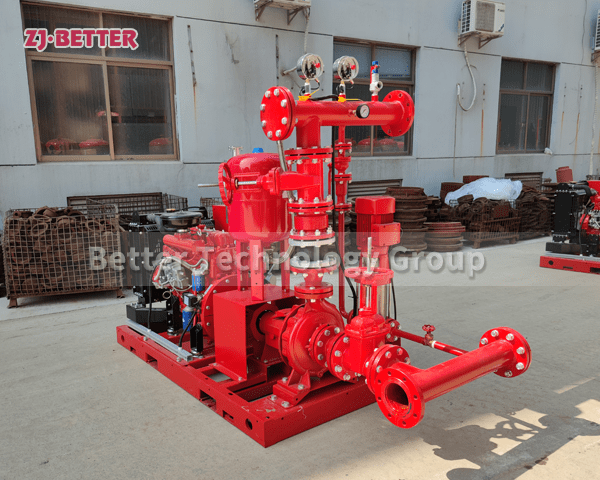

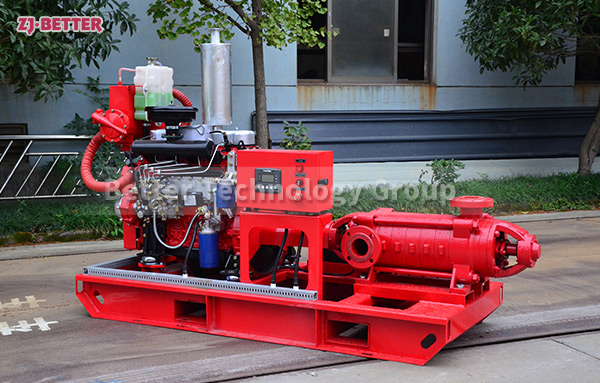

Better factory hot sale electric fire pump and diesel fire pump

XBD, XBC electric fire pump units and diesel engine fire pump units meet the national standards GB6245-1998 “Fire Pump Performance Requirements and Test Methods”, GB/T1147-1987 “General Technical Conditions for Internal Combustion Engines”. They can be equipped with ISG, IS, S, D and other pump types respectively, forming various structural types such as pipeline type, vertical multi-stage, horizontal single-stage cantilever type, horizontal split, horizontal multi-stage, etc., to be suitable for various working conditions Use under different conditions (different power, different speed, different materials, etc.).

XBD and XBC units are mainly suitable for fire protection engineering of steel, metallurgy, electric power, petroleum, chemical industry, construction, port and other operations, emergency water supply for blast furnace, continuous casting, converter and other accidents, power plant emergency water supply for power failure, nuclear reactor safety protection cooling water supply, And other water supply projects that require automatic control.

XBD electric fire pumps are driven by motors from well-known manufacturers. At the same time, it can be equipped with low-voltage, high-voltage and explosion-proof motors with different protection levels according to the user’s use environment and conditions. It is characterized by simple operation and maintenance, low noise, and less equipment requirements.

XBC diesel engine pump set is powered by 10-1000KW series of diesel engines produced by Cummins and well-known domestic diesel engine manufacturers. It is assembled with the water pump through high-elastic couplings, clutches, reducers, etc., and has the characteristics of quick start, reliability, strong emergency response capability, compact structure, and convenient protection. It has the functions of manual, automatic, automatic switching, automatic charging, automatic protection (overspeed, low oil pressure, three start failures, high water temperature, low battery voltage alarm, shutdown protection, etc.), emergency lighting, remote monitoring connection and other functions. In order to ensure the normal operation of the unit in a cold climate below 5°C, the unit can be equipped with a cooling water preheating device.

Both units can provide automatic control cabinets to achieve the purpose of automatic control, remote monitoring and remote control.