Beyond Grid Constraints: Diesel-Driven End-Suction Pumps for Remote Fire Safety Applications

Diesel engine driven horizontal pumps offer reliable fire protection in remote areas, overcoming power limitations with high efficiency, adaptability, and intelligent control—ideal for mountains, oil fields, and tunnels.

With the rapid development of urbanization and infrastructure construction, fire safety has become a key component of public security systems. However, remote areas, mountainous regions, islands, and places with underdeveloped power infrastructure often face severe challenges when dealing with fire emergencies. Especially under circumstances where power is limited or completely cut off, ensuring the stable and efficient operation of firefighting systems becomes a critical concern. The diesel engine driven horizontal pump emerges as an ideal solution for these scenarios, offering autonomous operation, flexible deployment, and robust performance.

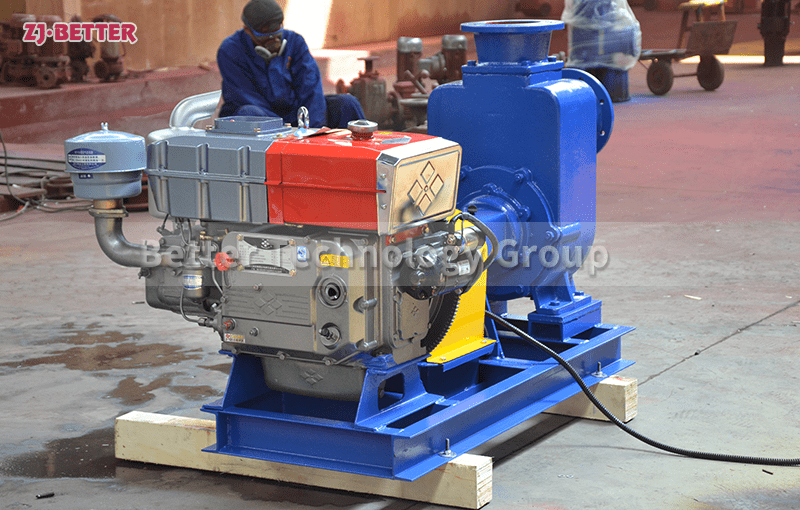

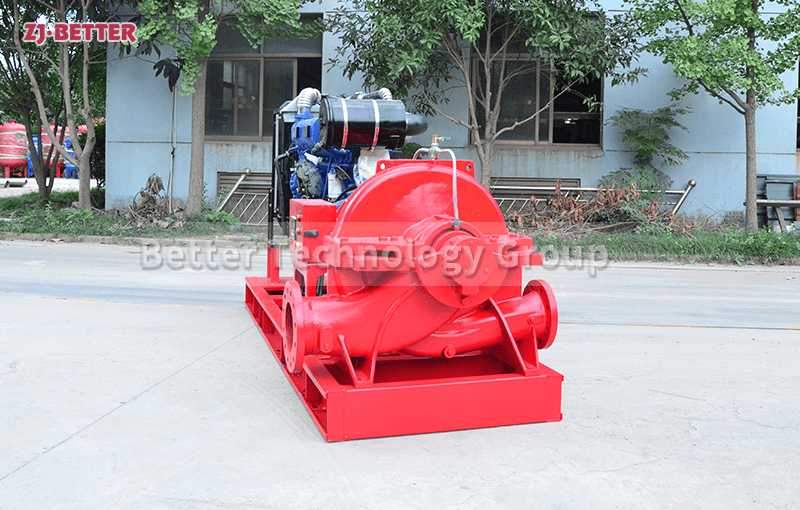

Unlike traditional electric firefighting pumps, the diesel horizontal pump is powered solely by a diesel engine, eliminating the need for grid electricity. This key feature solves the issue of unreliable or absent electrical supply and offers a reliable alternative for post-disaster zones, remote constructions, and off-grid facilities. Its horizontal shaft structure ensures balanced mechanical operation and minimal vibration, supporting long-term high-efficiency water delivery. This pump type integrates seamlessly with sprinkler systems, hydrants, water cannons, and other fire suppression equipment, ensuring optimal compatibility and system cohesion.

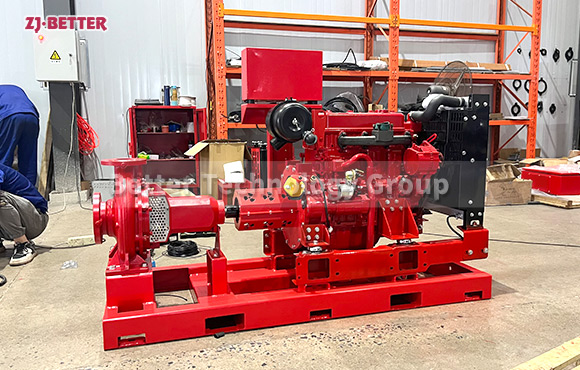

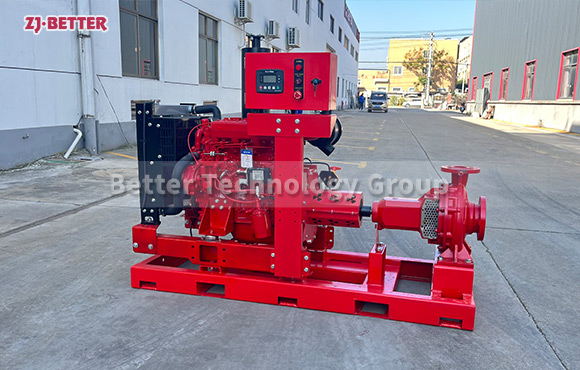

One of the main challenges in building fire protection systems in remote locations is the difficulty of transport, prolonged installation timelines, and maintenance complexity. The modular design and easy deployment of diesel engine driven horizontal pumps significantly reduce installation difficulties. No electrical wiring is required for commissioning, making them ideal for early-stage projects that lack power access. The integrated base frame enables quick lifting and assembly, minimizing civil works and saving valuable time. Technological advances in modern diesel engines have also enhanced fuel efficiency, reduced emissions, and lowered operational noise, aligning with global green construction standards.

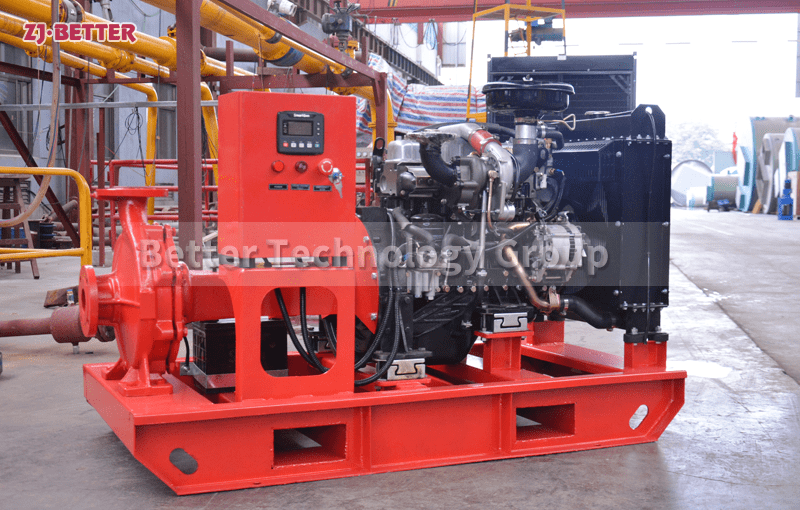

Operationally, these pumps deliver exceptional environmental resilience and stability. Whether in extreme cold, humid, or dusty conditions, they can start quickly and deliver rated flow and pressure without compromise. Combined with intelligent control panels and automated startup systems, they support remote monitoring and fault diagnostics, reducing the need for manual supervision and enhancing operational safety.

From a performance standpoint, diesel horizontal pumps are typically equipped with high-power, multi-cylinder engines capable of rapid response. The pump body is made from premium cast iron or stainless steel with special anti-corrosion coatings, making it suitable for various water sources including industrial water, surface water, and even seawater. The ability to deliver high flow rates and high heads makes them suitable not only for conventional fire protection but also for demanding scenarios such as oil terminals, large factories, airports, and ports.

As digital firefighting systems continue to evolve, these diesel-driven pumps are increasingly integrated with IoT and edge control systems, supporting real-time operational intelligence. Sensors monitor temperature, oil pressure, RPM, and exhaust emissions, enabling preemptive alerts and automatic backup activation in case of anomalies. This “smart standby” mode enhances the practical reliability of unmanned fire stations in remote areas, reducing the need for manual intervention.

Diesel engine driven horizontal pumps have already seen widespread adoption globally in tunnels, mines, oil & gas fields, and forest fire applications. In a western border oil depot project, where electric supply was inconsistent, diesel pumps were selected as the primary fire suppression solution. During real-world drills, the system operated continuously under sub-zero and high-altitude conditions, completing all tasks flawlessly. The project was highly rated upon inspection, with stakeholders emphasizing the reduced supply risk and enhanced safety assurance.

In conclusion, diesel engine driven horizontal pumps offer a critical advancement in overcoming electricity dependency in firefighting applications. Their independent operation, adaptability, efficiency, and intelligence make them an irreplaceable component of fire protection systems in remote and complex environments. As new materials and control technologies continue to develop, these pumps will play an increasingly vital role in upgrading global fire protection capabilities and resilience.