Emergency Solutions Beyond Space Constraints: Engineering Value of Compact Diesel Fire Pump Systems

Compact diesel fire pump units offer high-efficiency water supply, independent operation, and intelligent control, making them ideal for confined spaces, remote projects, and emergency scenarios—maximizing fire safety system performance.

In the face of increasingly complex urbanization and industrial expansion, fire safety systems today must overcome limitations in space, environmental complexity, and unstable energy supplies. Traditional firefighting equipment is often bulky and cumbersome, which poses significant challenges for integration into projects with limited spatial resources. In confined environments such as underground garages, urban renovation sites, remote regions, or temporary construction zones, the need for a reliable, flexible, and high-performance emergency fire system becomes critically important. To meet this demand, compact diesel-powered fire pump units have emerged as a highly effective solution, delivering robust emergency water supply within limited space, thereby becoming a vital component in modern engineering.

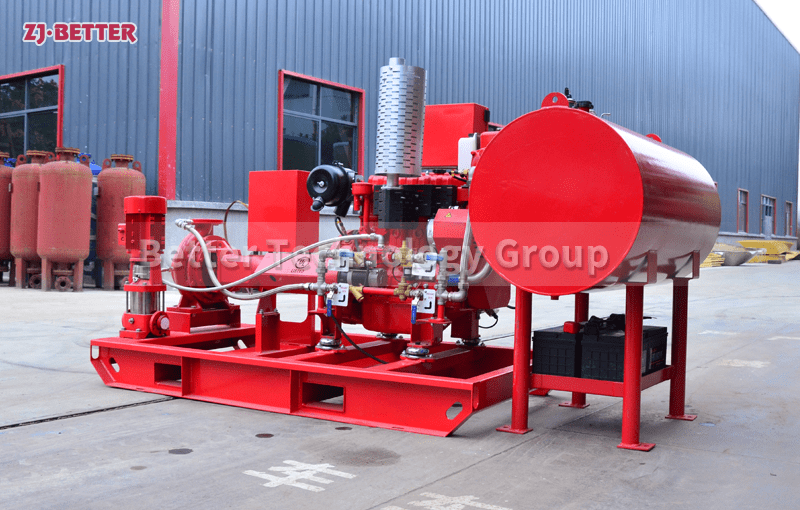

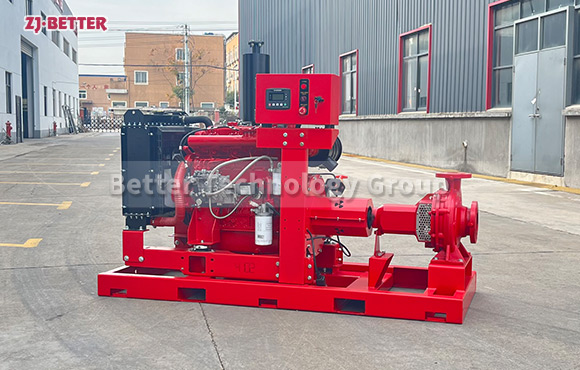

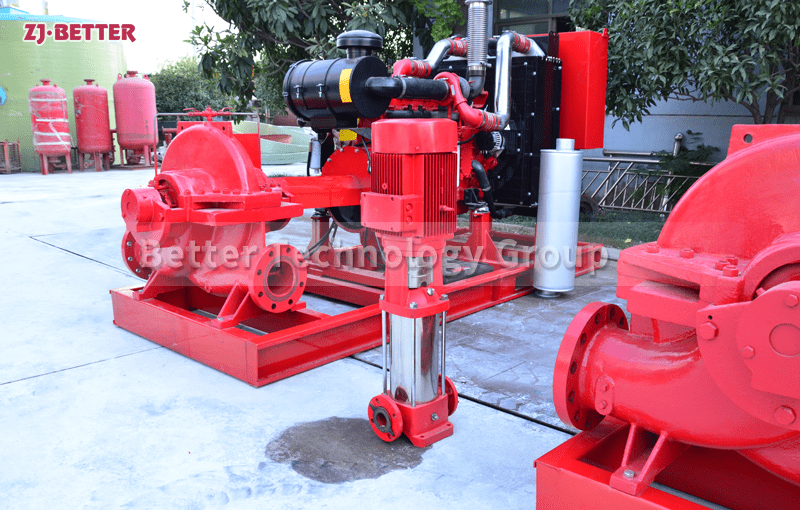

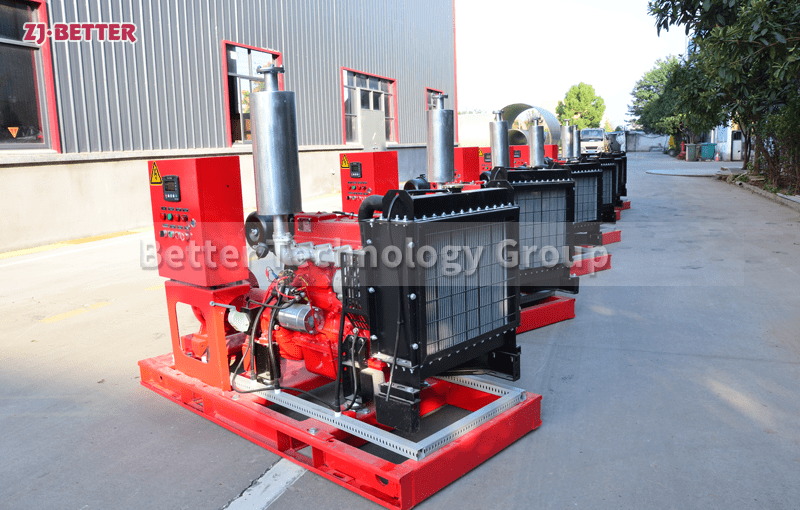

The standout feature of compact diesel fire pump units is their “space-saving design without sacrificing performance.” These units consolidate the power unit, pump body, control system, and fuel system onto a reinforced and compact base. While ensuring high flow and head capabilities, this streamlined layout significantly reduces the installation footprint and enhances flexibility during transportation and deployment. Such design excellence makes these pumps ideal for tight spaces like basements, narrow corridors, mobile emergency systems, and rapid deployment scenarios.

With diesel engines as their core power source, these pump units can operate independently from external power grids. This ensures uninterrupted operation during blackouts, power outages, or in off-grid locations. Modern diesel engines are known for their fuel efficiency, strong torque, stable performance, and easy start-up. When paired with high-performance centrifugal or self-priming pumps, these units can deliver flow rates of several hundred cubic meters per hour and head outputs ranging from tens to over a hundred meters—suitable for a wide variety of fire protection needs.

The integrated intelligent control systems further enhance the pump unit’s automation and smart monitoring capabilities. Features include auto-start, self-diagnosis, remote monitoring, and data logging. Operators can monitor operating conditions, fuel levels, maintenance schedules, and fault alerts in real-time through user-friendly panels or connected communication systems. This significantly reduces manual oversight requirements and increases emergency responsiveness—particularly valuable for multi-site management and remote project installations.

On the material and manufacturing front, these units use high-quality cast iron, ductile iron, stainless steel, and brass for critical pump components such as impellers, casings, and shaft seals. Renowned diesel engine brands are adopted for the powertrain, complemented by advanced filtering, efficient cooling systems, and anti-vibration mounts to ensure long service life and stable operation even under heavy-duty conditions.

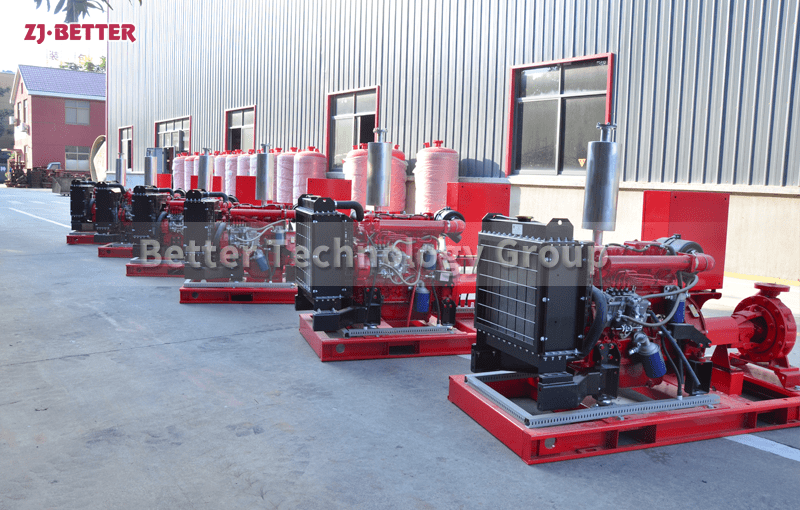

Due to their compact structure and robust performance, compact diesel fire pump units are widely used across numerous emergency and special environments. These include underground structures (subways, parking facilities), petrochemical corridors, wind farms, temporary construction sites, highway tunnels, and mountainous projects. In such scenarios, these units can serve as either primary fire protection systems or backup water sources, ensuring a quick and reliable emergency response.

To better serve global markets, optional configurations include containerized enclosures, noise reduction hoods, explosion-proof versions, and multilingual interfaces. These upgrades improve safety, environmental compatibility, and international usability. The modular design also supports standard shipping and fast installation, reducing logistics costs and project delays.

From a system integration perspective, these diesel pump units can be connected with electric pump systems, pressure regulators, and alarm panels to form a fully integrated “fire protection water supply solution.” This enables multi-source redundancy, automatic switching, and intelligent dispatching—maximizing system reliability and safety.

In summary, compact diesel fire pump units are more than just compact, powerful emergency devices. They represent the future of high-performance, space-efficient fire protection systems in constrained environments. With increasing emphasis on life safety, risk mitigation, and operational efficiency, these small yet powerful units will continue to play a crucial role in high-density urban areas, critical infrastructure, field operations, and international engineering projects.