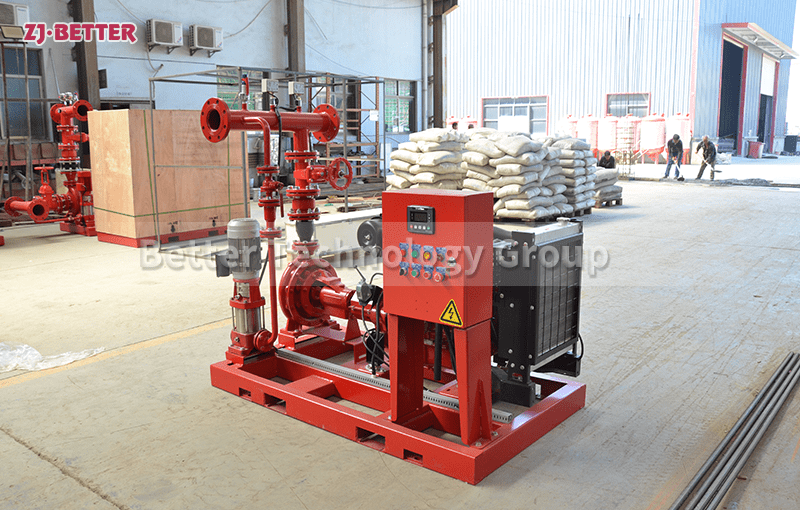

Hand-held diesel fire pump is easy to use

The hand-carried diesel fire pump refers to a motorized fire pump that is carried by manpower. Because of its light weight, small geometric size and convenient use, it has a wide range of applications and is rarely restricted by roads. One of the important fire extinguishing equipment.

The hand-held diesel fire pump includes a main body, which is equipped with a fuel tank, a gasoline engine connected to the fuel tank, a single-stage centrifugal pump, a water inlet, a water outlet, a charging module for charging, a battery for storing electricity, a frame, fan blades and The power input shaft installed in the middle of the fan blade, the end of the power input shaft is fixedly connected with a hollow starting block, and the hand-held mobile fire pump includes a hand-operated device that drives the starting block to rotate. When it is found that the battery is out of power during fire fighting, the gasoline engine in the fire pump can be started by the manual starter device, so that the fire can be started in the fastest time. Therefore, the hand-held mobile fire pump has both electric start and manual start. Function.