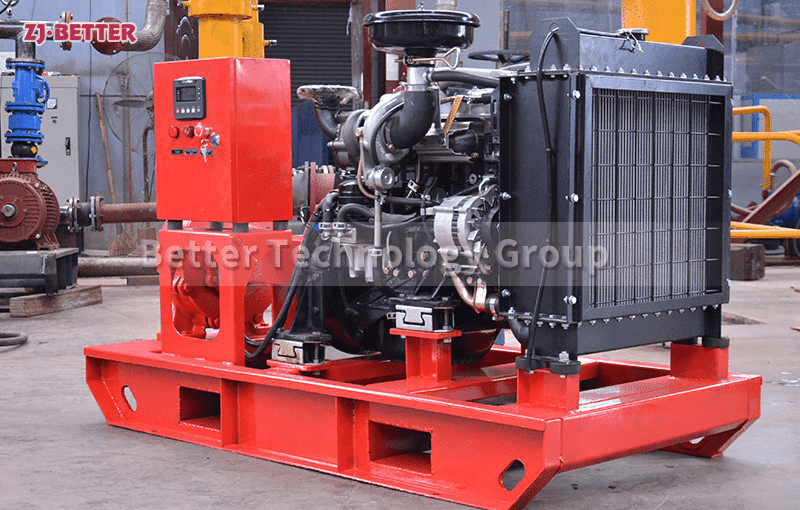

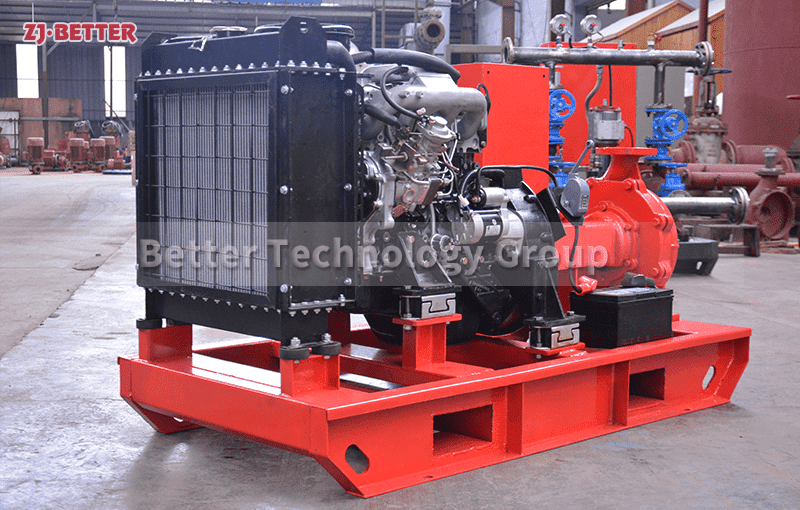

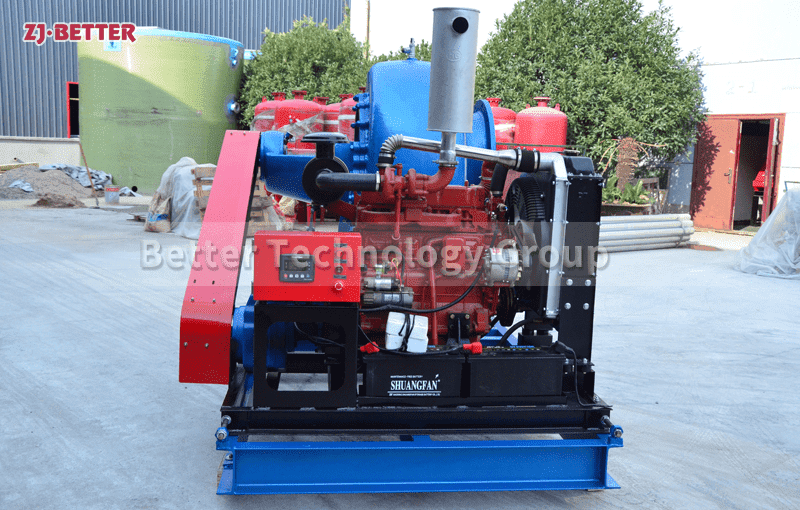

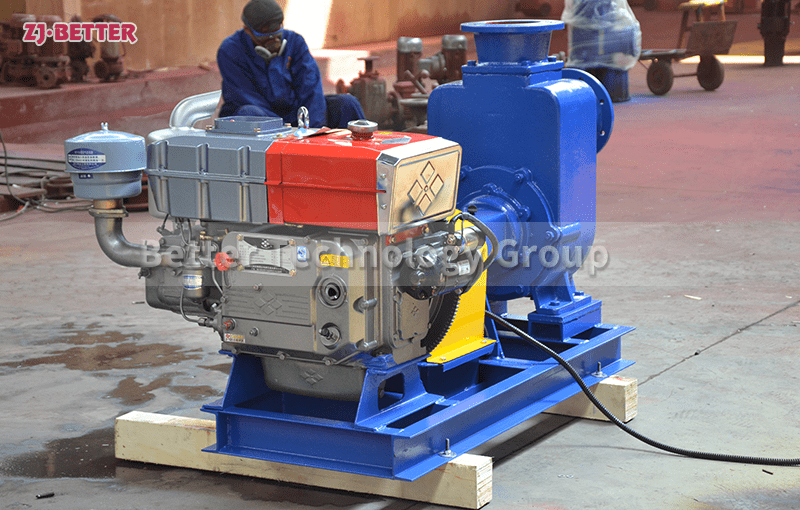

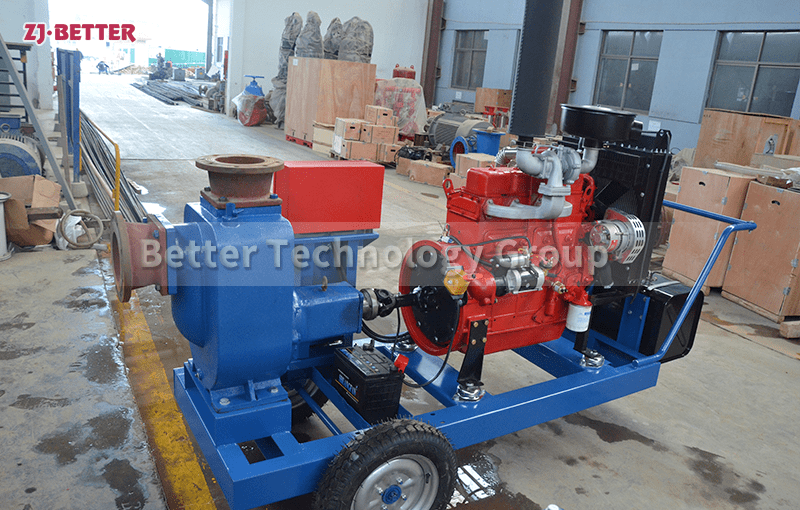

Fire pump set equipment with superior performance

The fire pump is usually equipped with a local control cabinet. The control cabinet does not have a transfer control switch for automatic and manual conversion, but the automatic control loop leaves start and stop contacts, which are connected to the fire alarm system control module. In addition, according to the relevant regulations, the system using the bus linkage control should also be set in the fire control room with buttons that can directly start and stop the pump.

When the fire alarm system receives the signal of the fire hydrant start pump button, the control module automatically starts the fire pump and collects its feedback signal.

Fire pump is a kind of water pump. Due to its superior performance, fire pump is not only used in the field of fire protection, but also used in many other fields. Such as: domestic water supply system, domestic drainage system and so on. Like other water pumps, the flow and head are its important parameters. Many customers mainly look at the flow and head parameters when choosing a fire pump.

Simply put, the head is the high distance that the pump can deliver water, that is, how high the pump can spray the water. And the head of the pump and the outlet pressure are directly related, the higher the outlet pressure of the pump, the larger the head accordingly.