Better Technology Group Co.,Ltd was founded in 2004, located in Quzhou, Zhejiang, China, which is near Yiwu.

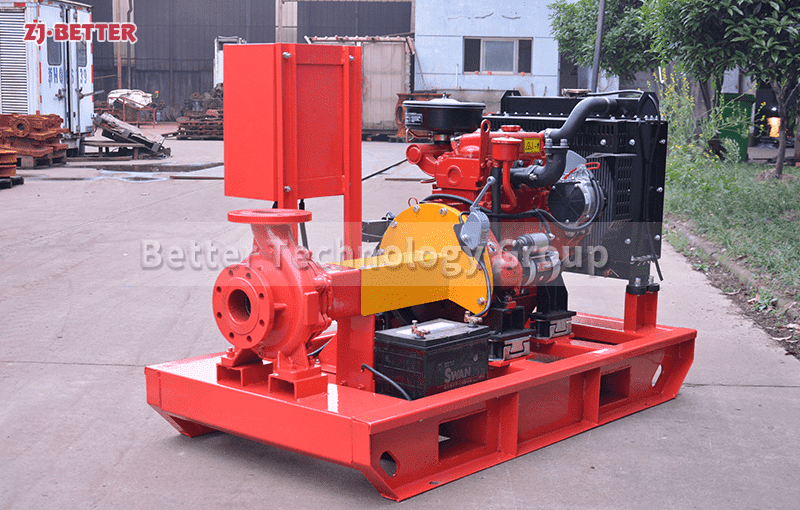

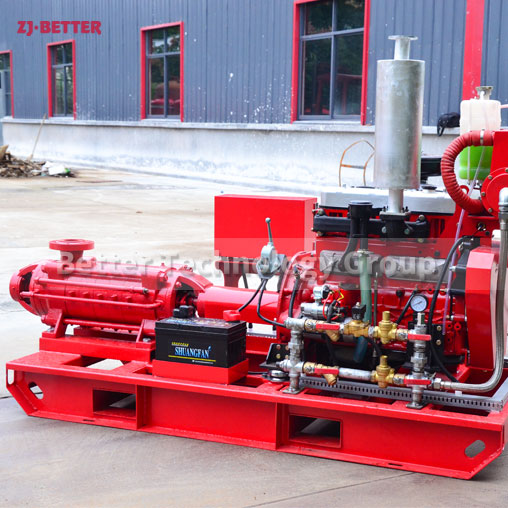

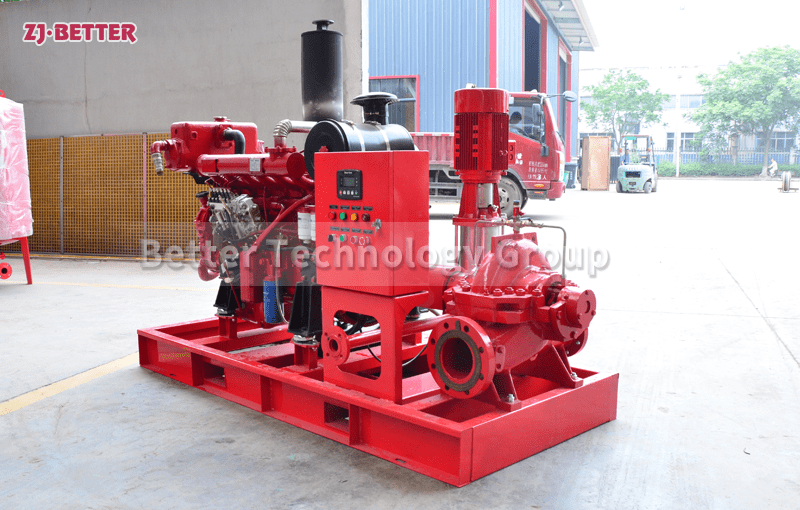

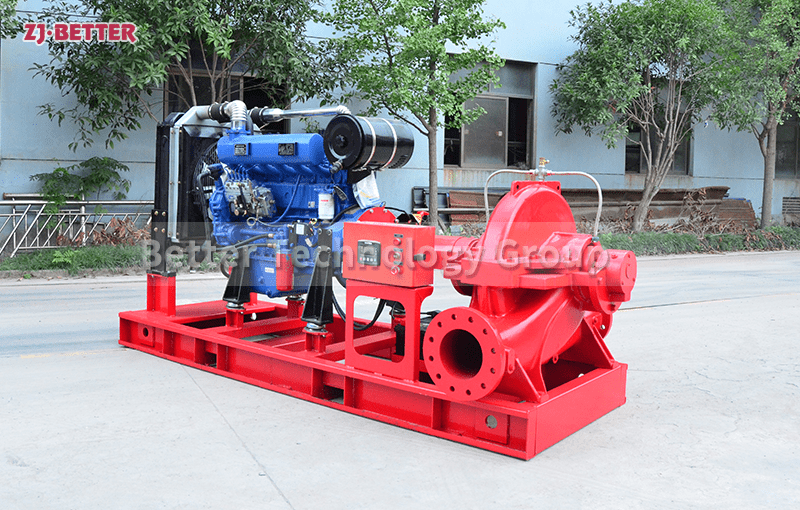

We are an import and export enterprise which integrating design, development, production and sales of fire pump, motors, electrical automation controller. After 17 years of solid operation, we have acquired 20 product-related invention patents, successively won many honors, such as national high-tech enterprise, director unit of Fluid Equipment Professional Committee of China Association of Water Conservancy enterprises, science and technology enterprise of Zhejiang, etc.

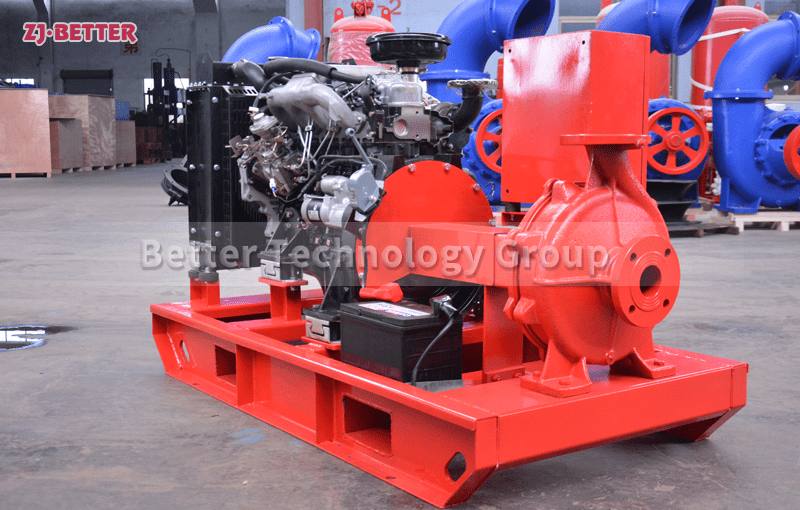

We have fixed capital of 80 million, more than 200 workers, including 26 engineering technical personnel. Better Technology has engineers and technicians with middle and high-level titles that account for more than 20% of all employees. We have new factory area on the process to build, cover 60 acres, it is will more for the fire fighting pump for export.. we have professional team for design and product, professional team for sales…we are your best choice for fire fighting pump