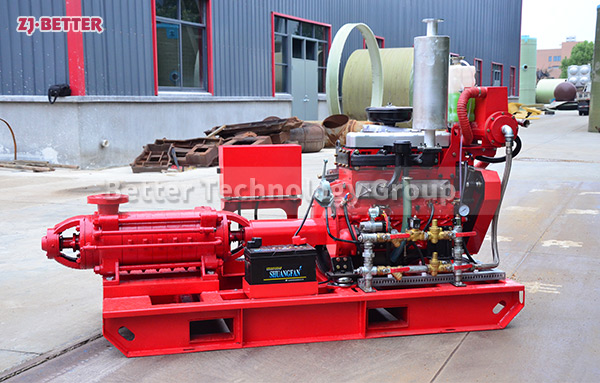

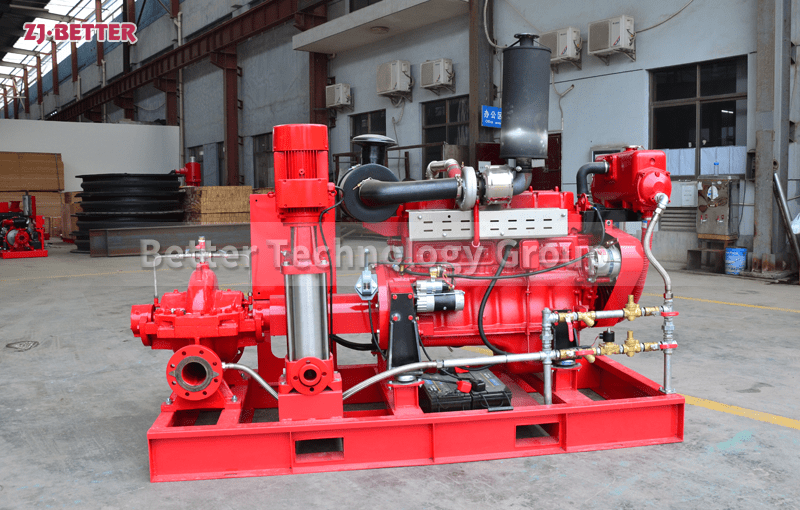

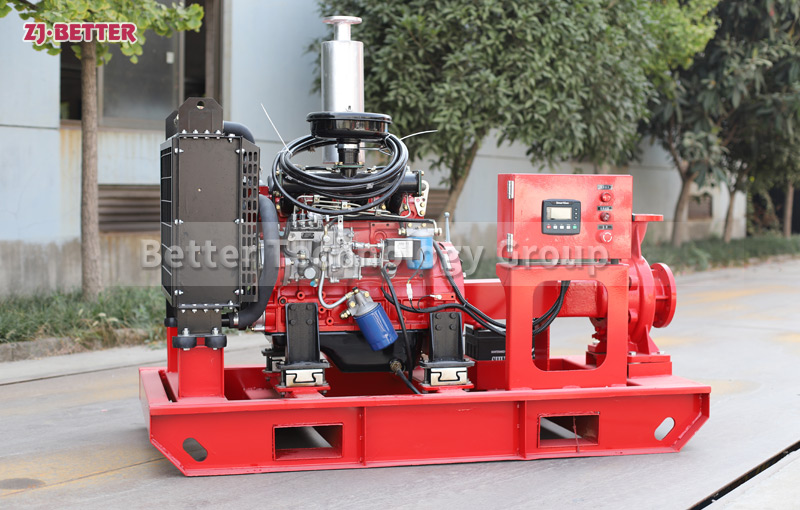

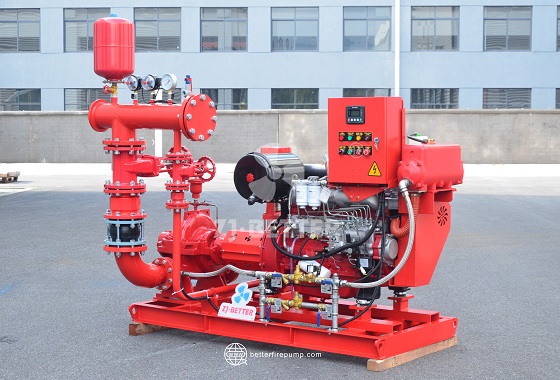

Self-Starting Diesel Fire Pump Unit Ensures Reliable Water Supply in Emergencies

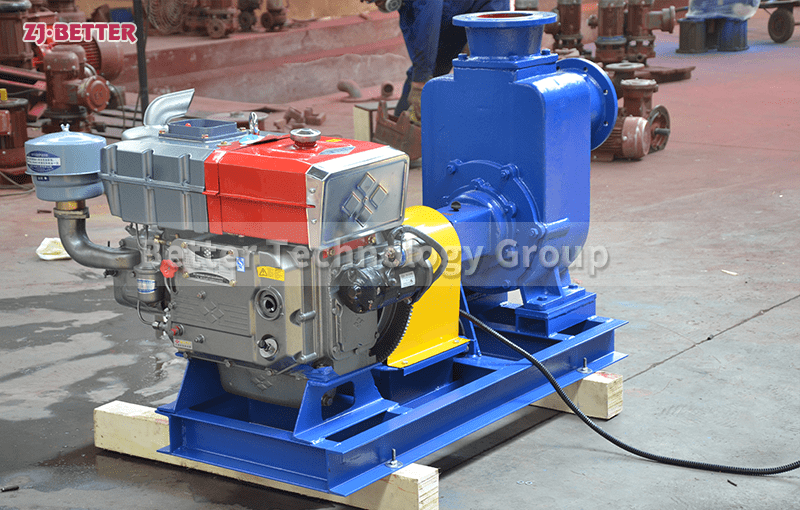

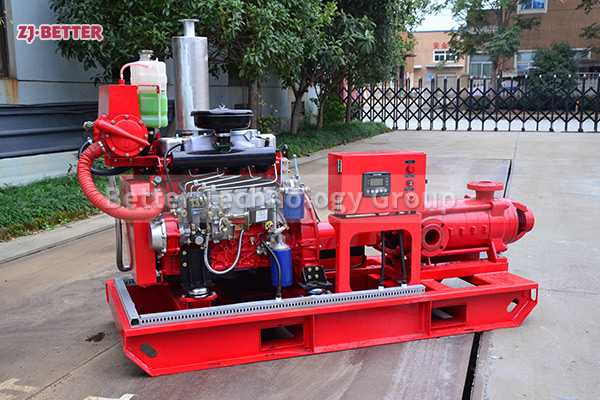

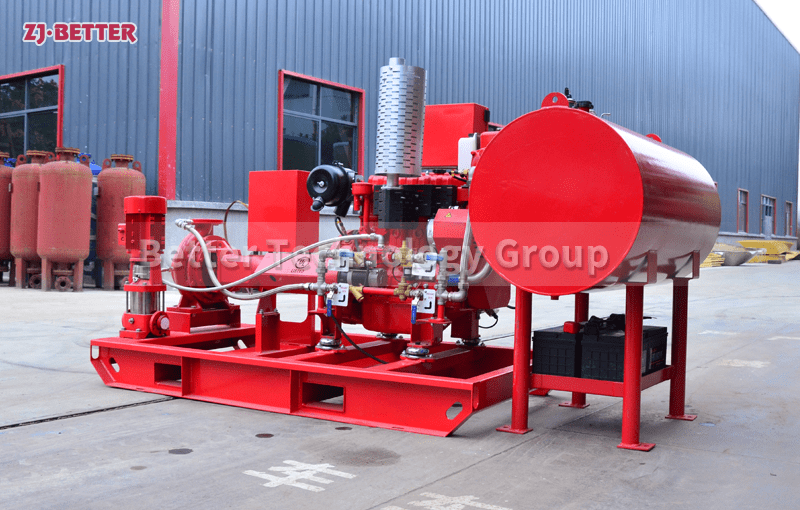

In critical moments, a reliable water supply is the key to saving lives. Our Self-Starting Diesel Fire Pump Unit is specifically engineered to respond to emergencies such as fires and power outages. Equipped with a high-performance diesel engine, it can automatically start without any external power source, ensuring immediate and stable water supply to the fire protection system.

The unit features an intelligent control panel with real-time monitoring, auto-diagnostics, and fault alarms, enabling true 24/7 automated standby operation. Its modular design allows for easy transport, installation, and maintenance, making it an ideal solution for high-rise buildings, petrochemical sites, industrial parks, and warehouse facilities.

Choosing this diesel-driven fire pump unit means more than selecting equipment—it means building a robust line of defense for safety.

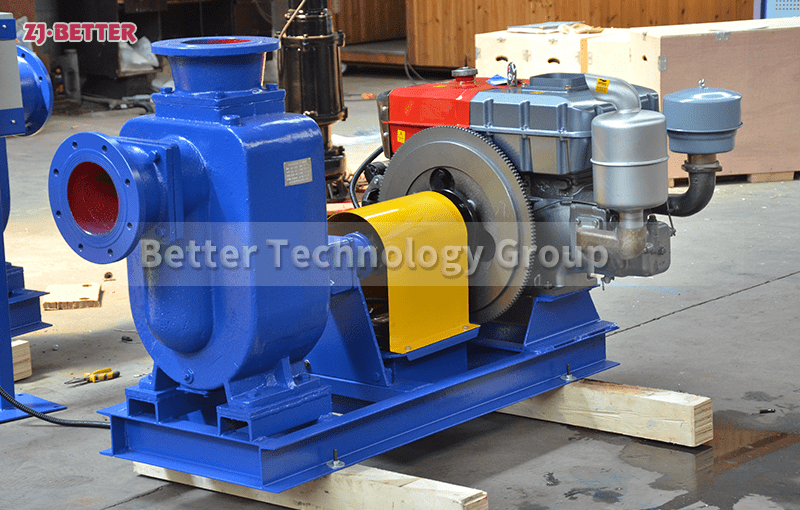

Specializing in the research and manufacturing of fire water supply systems, this enterprise has grown into a professional provider of firefighting pump solutions through years of industry experience and technical expertise. Its product lineup ranges from electric and diesel-driven pump units to fully automated pressure-maintaining systems, serving a wide spectrum of critical facilities such as high-rise buildings, industrial complexes, airports, ports, and petrochemical zones.

Equipped with advanced manufacturing tools and comprehensive testing platforms, the company ensures reliable performance and high-quality output from every unit produced. With a dedicated R&D team committed to innovation and design optimization, the company consistently meets and exceeds global fire safety standards.