Diesel-Driven Fire Pump for Continuous Flow During Power Outages

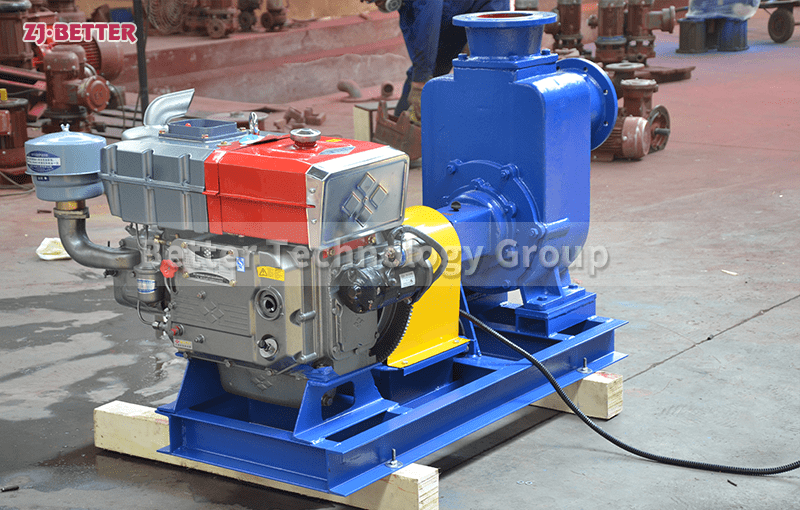

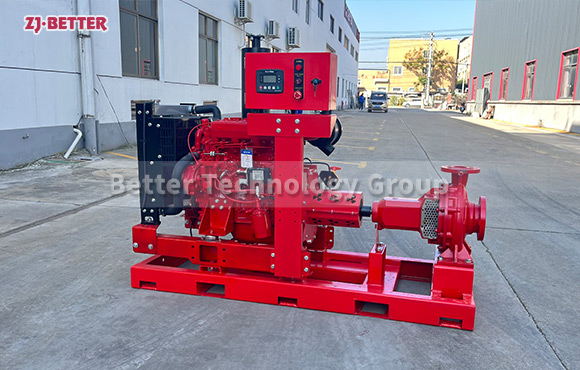

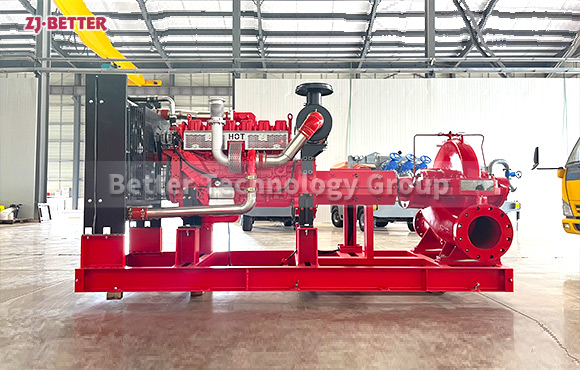

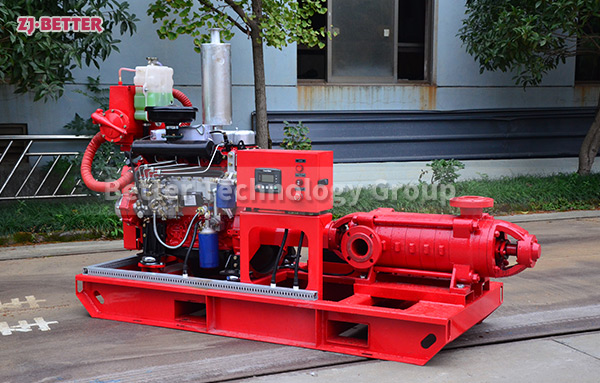

In the face of unpredictable fire emergencies, uninterrupted water flow is vital for efficient firefighting. This diesel-powered fire pump is designed for autonomous operation, capable of rapid start-up and continuous high-pressure water delivery even in the absence of an external power source.

Driven by a heavy-duty diesel engine and equipped with a high-performance pump and intelligent control system, it significantly enhances the response time and reliability of fire protection systems.

With its modular structure and compact footprint, the unit is perfectly suited for critical environments such as oil depots, docks, power plants, and airports—providing a powerful and dependable solution to handle emergency fire incidents.

We are a professional manufacturer and solution provider specializing in fire pump systems, with many years of deep industry experience and strong technical expertise. Our product portfolio includes electric fire pump units, diesel engine fire pump packages, dual power control systems, sprinkler and pressure-stabilizing equipment, and complete constant pressure water supply systems. Together, these form a comprehensive product lineup that meets the demanding requirements of modern firefighting projects.

Equipped with advanced production lines, automated machining centers, and full-system testing platforms, we maintain a streamlined production process—from component fabrication to system integration and performance testing—ensuring every unit meets both national and international quality standards. Our R&D team is dedicated to innovation and continuous improvement, offering tailored design, pump selection, and turnkey support services to meet the specific needs of each client.

Our systems are widely deployed in high-rise buildings, industrial complexes, petrochemical facilities, power plants, urban infrastructure, and transportation hubs. Over the years, we have earned a solid reputation in both domestic and global markets. With robust pre-sales consultation, technical guidance, and after-sales support, we adhere to the principle of “quality first, service driven” and are committed to delivering safer, more efficient firefighting solutions worldwide.