Boosting Emergency Efficiency with Integrated Design: Compact Diesel Fire Pump System Solution

Compact diesel fire pump system with integrated layout and reliable performance, ideal for power-unstable environments and complex scenarios. Enhances emergency water supply efficiency and supports global-standard customization.

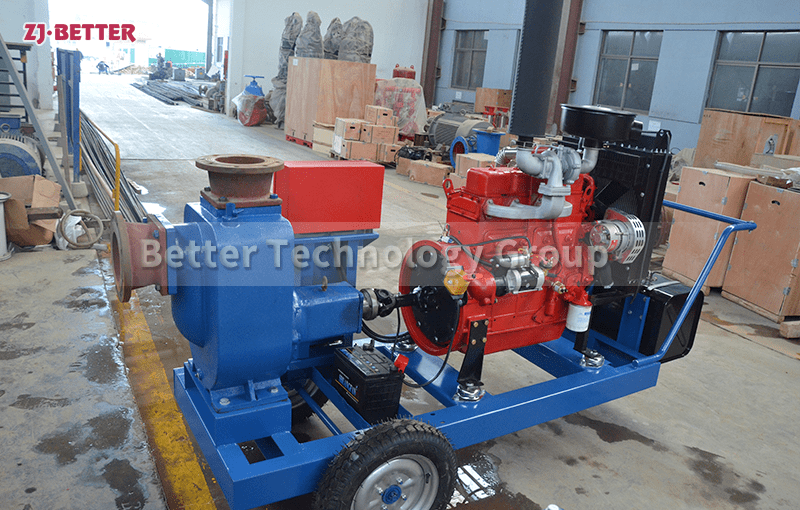

In modern fire protection systems, compact diesel fire pump systems are gradually becoming the preferred solution for urban buildings, industrial facilities, and remote locations. Compared to traditional large-scale systems, this type of product features a compact structure, rapid response, easy installation, and strong adaptability, demonstrating exceptional efficiency and reliability under harsh conditions. Particularly in emergencies, its integrated layout design significantly reduces startup delays, enhancing overall emergency response speed and providing critical protection for lives and assets.

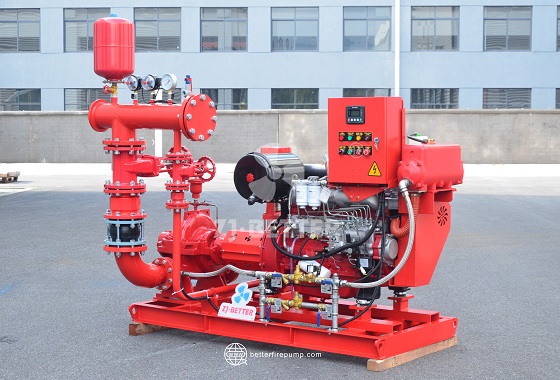

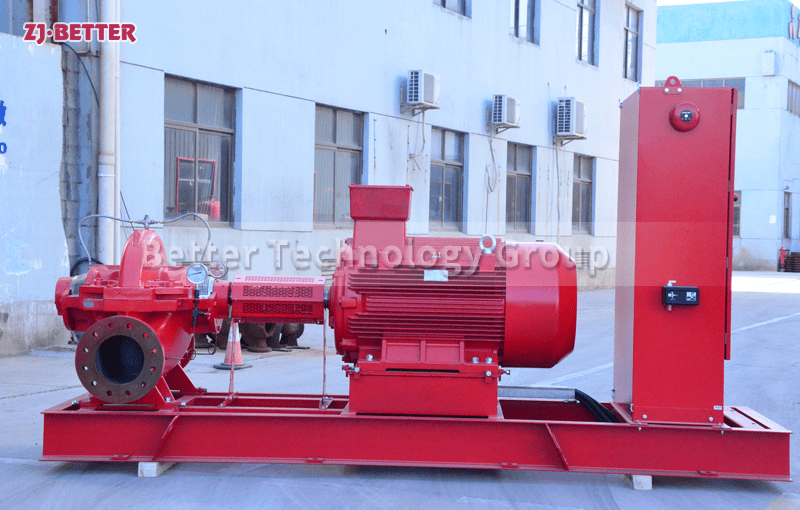

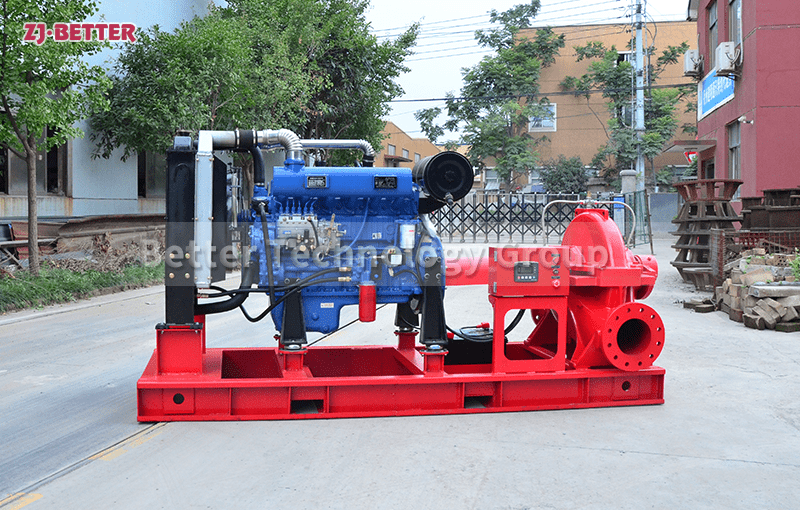

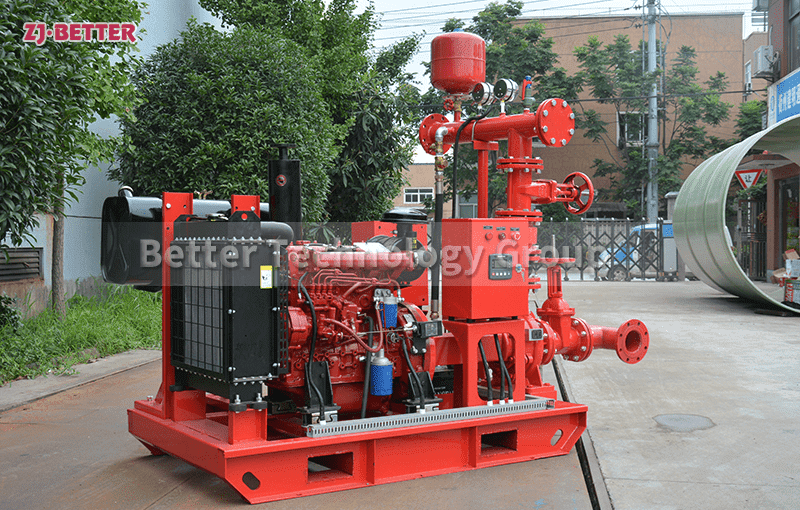

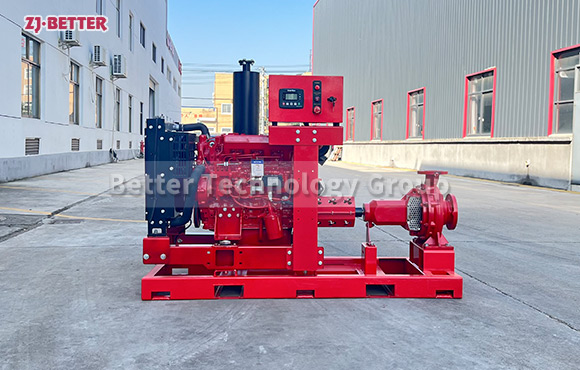

This equipment integrates the diesel engine, fire pump, control panel, fuel tank, piping, and base into a standardized platform, achieving a highly centralized structure. Such an integrated layout not only saves installation space and reduces system complexity but also simplifies daily maintenance, enabling efficient deployment even in space-constrained areas. Moreover, the product is designed with diverse performance requirements in mind, making it adaptable to various applications such as residential complexes, warehouses, substations, hospitals, highway pumping stations, and tunnels.

In terms of core components, the compact diesel fire pump system features a high-performance, stable diesel engine that ensures reliable operation under extreme temperatures, low voltage, or remote locations with unstable power supply. The paired fire pump is designed with high head and large flow, with the pump body made of high-strength cast iron or stainless steel, combining wear resistance and corrosion protection to extend service life. The control system includes an intelligent interface that supports automatic start/stop, self-diagnosis, alarms, and linkage functions, with multiple communication ports reserved for integration with upper systems like BMS and fire monitoring platforms.

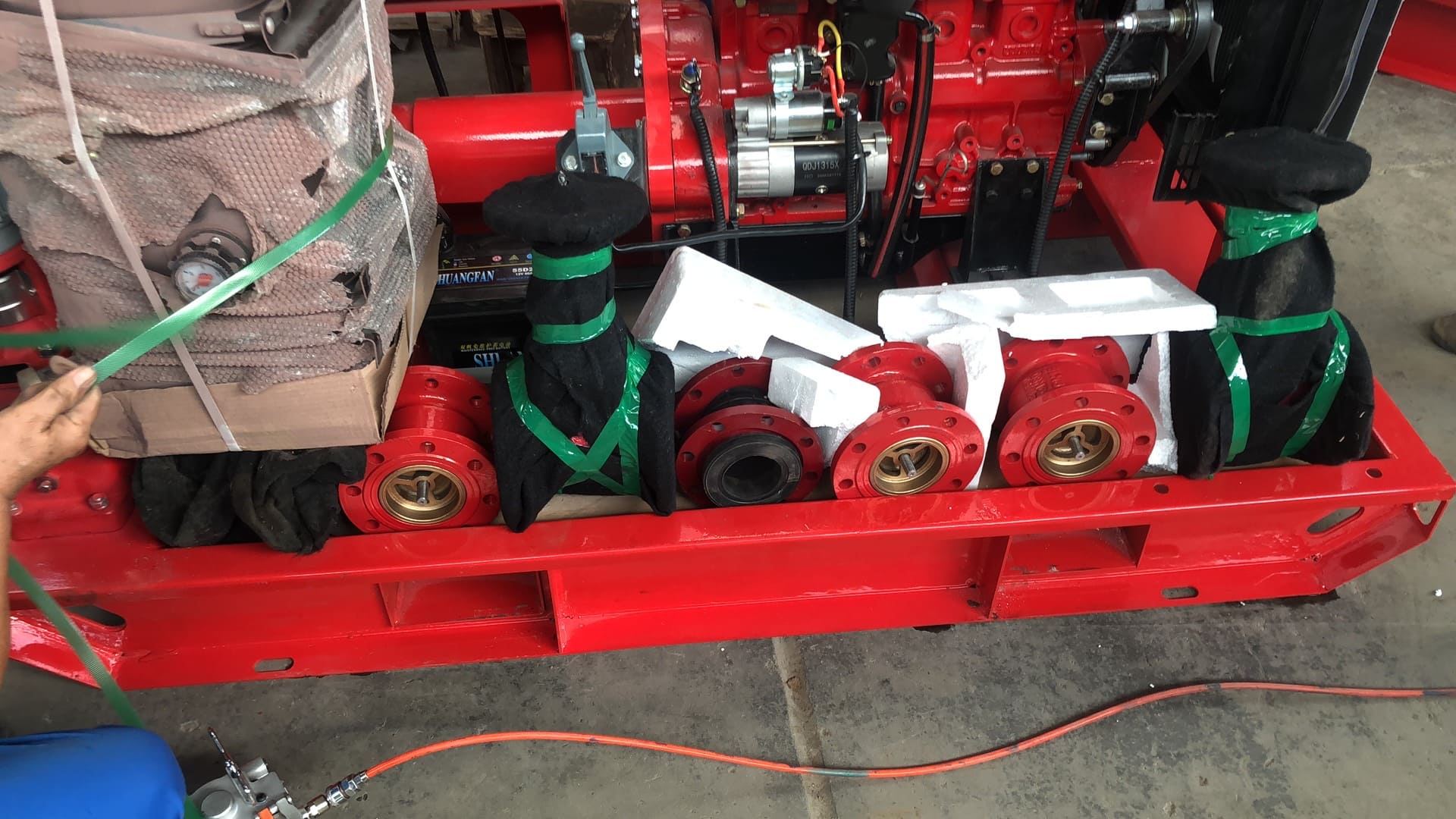

The system is designed with a focus on modularity and flexibility. Users can select different diesel engine and fire pump configurations based on actual needs, and optionally integrate components such as pressure tanks, starter batteries, auto-refueling modules, and remote startup systems. The base is constructed with heavy-duty steel, offering excellent anti-vibration, anti-corrosion, and waterproof performance, suitable for long-term outdoor operation across various climates and terrains. In terms of logistics, the compact layout and moderate weight enable convenient lifting and transport, ensuring fast on-site deployment and commissioning.

Customer feedback shows that this system features fast startup, stable operation, and easy maintenance, significantly enhancing the reliability and effectiveness of fire protection solutions. Especially in scenarios with unstable or unavailable grid power, the diesel-powered system’s independent operation capability becomes crucial, ensuring sustained water supply during firefighting. The product also holds CCC, ISO, CE, and other authoritative certifications, meeting mainstream fire safety standards both domestically and internationally, offering worry-free quality assurance.

It is worth noting that the system can be customized according to regional regulations, usage preferences, and specific client requirements, including unit color, control logic, language interface, and wiring methods, showcasing strong global adaptability. The manufacturer possesses extensive project experience and a robust engineering support team, offering one-stop services from solution design, drawing confirmation, custom production to technical guidance and after-sales service, helping clients achieve seamless system integration and project implementation.

In summary, the compact diesel fire pump system plays an increasingly vital role in modern firefighting with its integrated design, superior performance, flexible configuration, strong environmental adaptability, and outstanding emergency water supply capabilities. Whether for new projects or system upgrades, it serves as an ideal solution for main or backup pumps, contributing to the development of a safe, efficient, and reliable fire protection system.