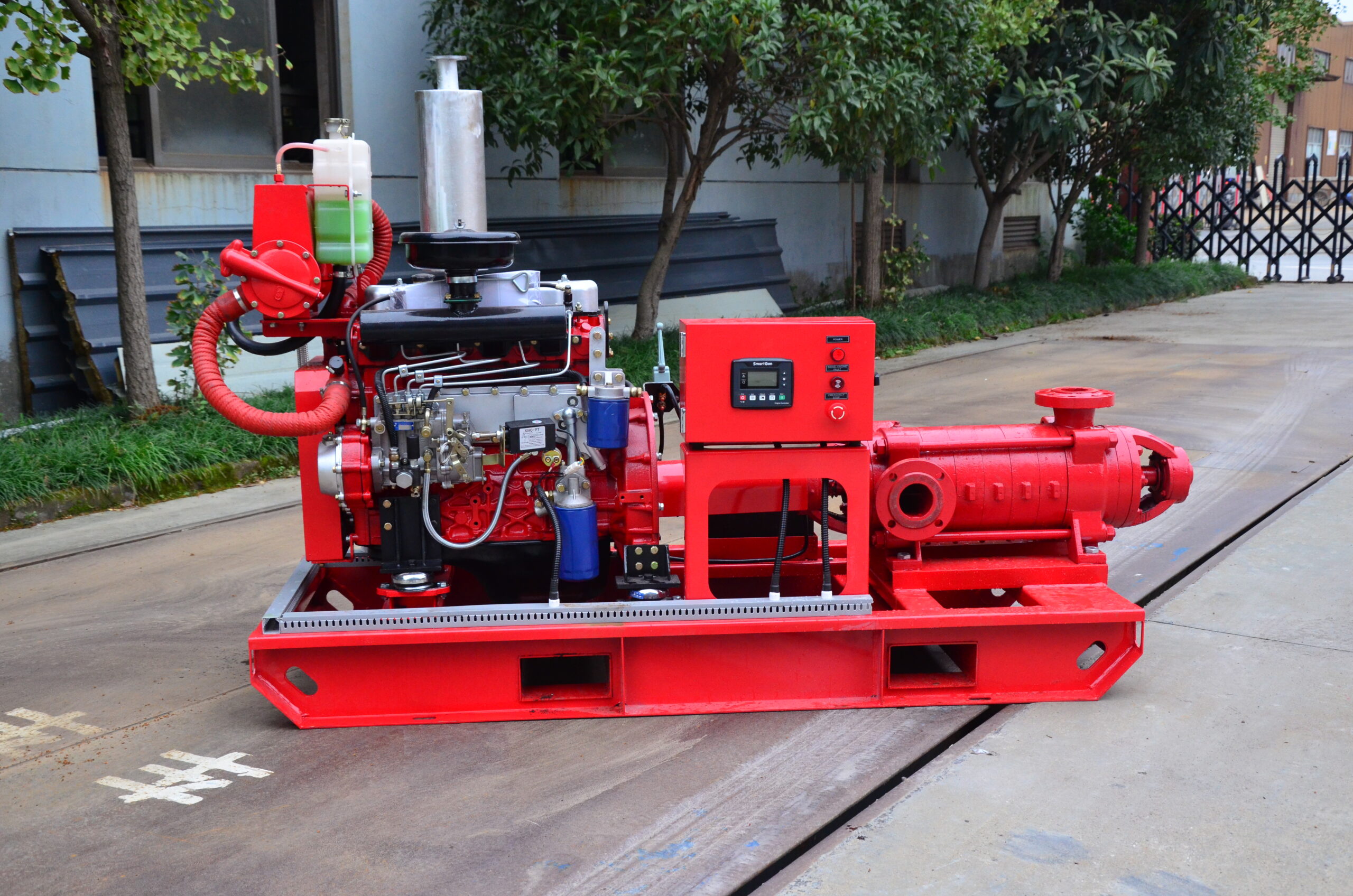

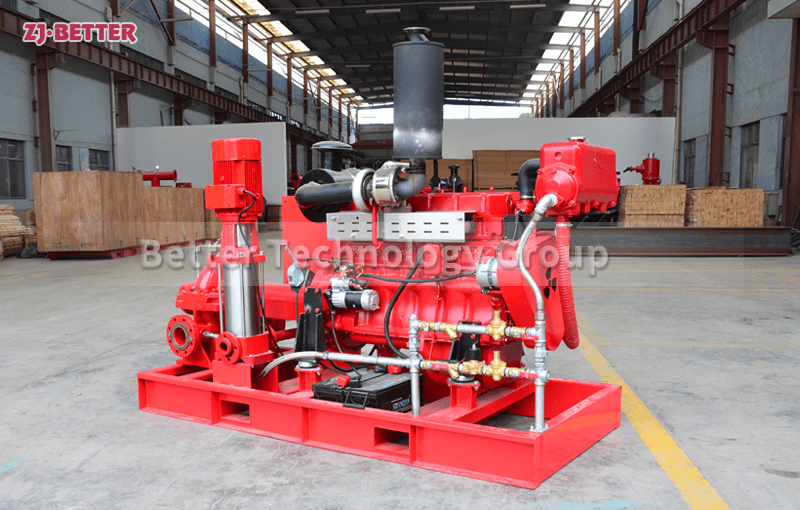

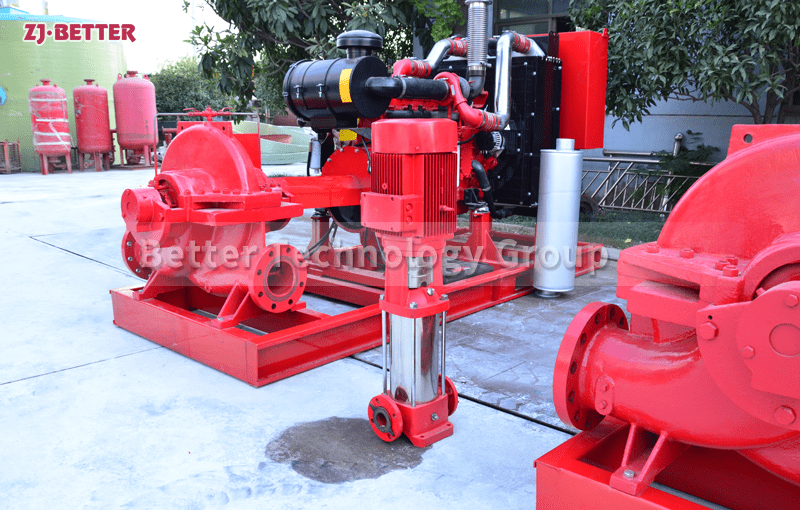

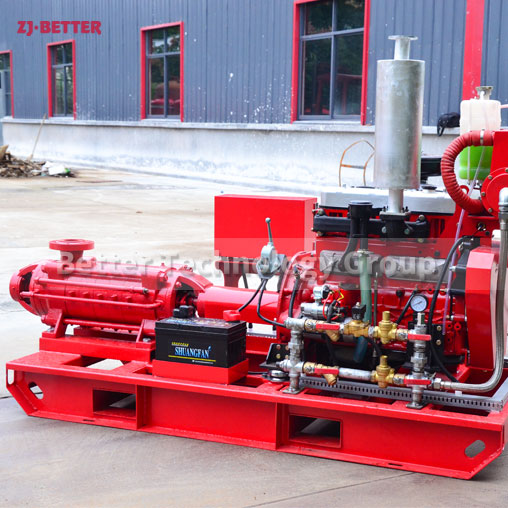

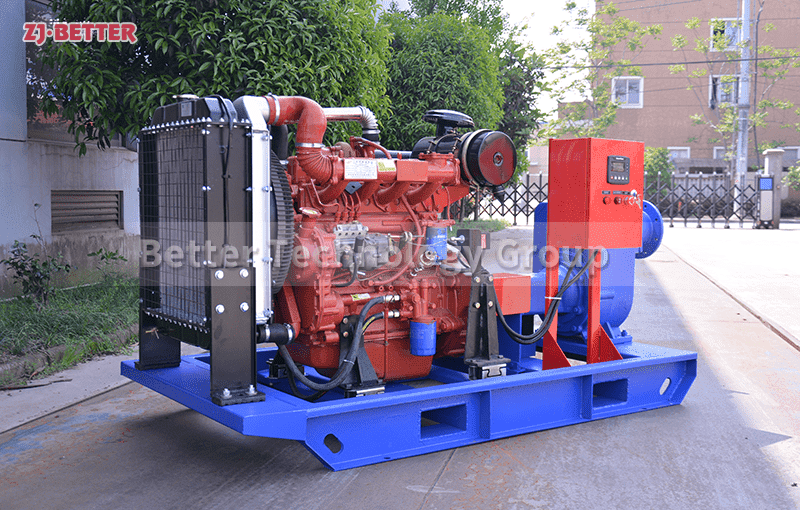

In today’s highly industrialized and risk-intensive operational environments, facilities such as petrochemical plants, power plants, shipping terminals, tunnels, airports, warehousing and logistics hubs, and high-rise buildings place extremely high demands on the response speed and independent power supply capabilities of fire suppression systems. As a core firefighting equipment designed for high-risk scenarios, the diesel-powered fire pump stands out for its grid-independent power supply, exceptional reliability, robust power output, and high system compatibility, making it an indispensable emergency firefighting power solution for numerous critical locations. Diesel-powered fire pumps form a complete integrated pump unit by combining a starting battery, fuel system, automatic control cabinet, water-cooled cooling system, and bypass piping system. They can rapidly respond in any sudden power outage or main system failure scenario, ensuring uninterrupted firefighting water supply at the site. Compared to traditional electric fire pumps, diesel-powered fire pumps not only have stronger self-sustaining operational capabilities but can also start normally under extreme conditions such as earthquakes, heavy rains, or explosions, thereby securing valuable emergency response time for the site. Their core power units are equipped with internationally renowned brand diesel engines, offering a wide range of power output, ample torque, and excellent fuel efficiency and low emissions. They are also equipped with high-performance single-stage or multi-stage centrifugal pump bodies, which can be precisely matched to the system’s designed head and flow rate to ensure stable and efficient water discharge with no pressure drop over long distances. For harsh environments, the equipment features thickened corrosion-resistant bases and heavy-duty vibration-damping structures, along with overall electrophoretic coating and surface rust-proof treatment, ensuring structural stability and sealing integrity even during long-term operation. It is suitable for high-temperature, high-humidity, and highly corrosive environments. In terms of intelligent control, the diesel-powered fire pump can be integrated with a dual-power switching module, automatic start-stop program, and fault self-diagnosis system to enable 24/7 unmanned operation. The control cabinet is equipped with a remote communication interface, supporting integration with building automation systems or fire monitoring platforms to achieve remote visualization of pump group operation status and warning linkage. The entire unit complies with multiple certification standards such as NFPA 20 and ISO, ensuring its universality and compliance in international engineering projects. More importantly, the diesel-powered fire pump can be customized with various modules such as soundproof enclosures, dual-machine interlocking systems, quick-connect hose interfaces, cold start systems, and large fuel tanks to fully meet the requirements for continuous power supply and multifunctional integration in high-risk scenarios. In actual application cases, whether in petrochemical tank farms, underground fire protection systems at large airports, or independent water supply stations at remote warehouses, the diesel-powered fire pump has demonstrated outstanding start-up responsiveness, continuous water supply capability, and fault stability, making it one of the most reliable core fire protection equipment in high-security facilities today. As urban development and industrial progress continue to advance, diesel-powered fire pumps with intelligent, modular designs and the ability to operate under extreme conditions will remain a key power pillar in future fire protection systems. They are not merely pieces of equipment but guardians of life safety in high-risk environments.