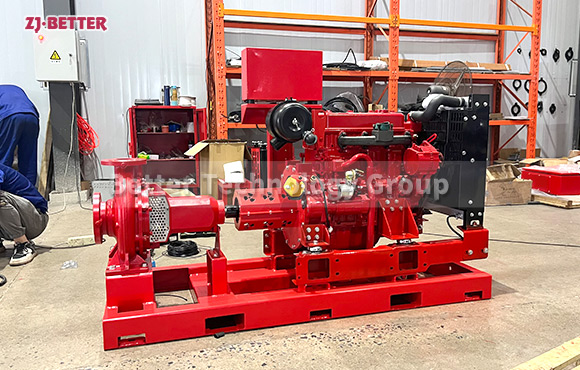

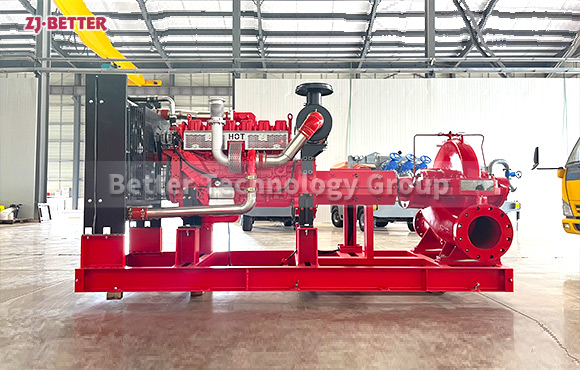

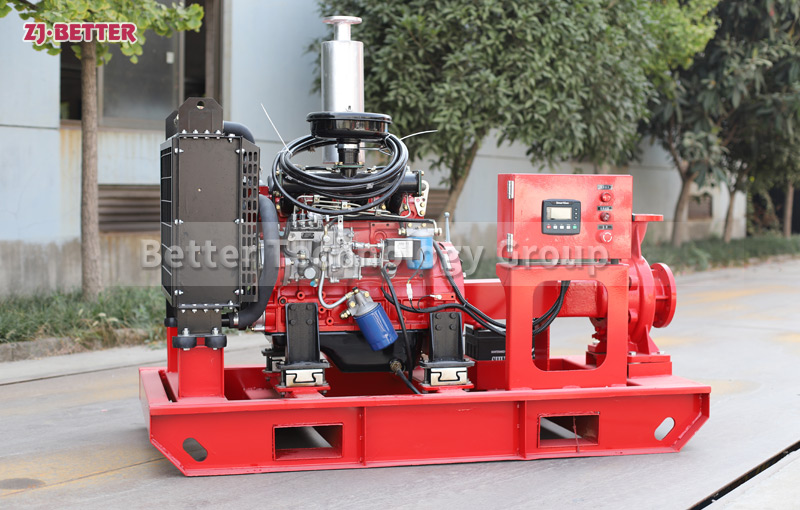

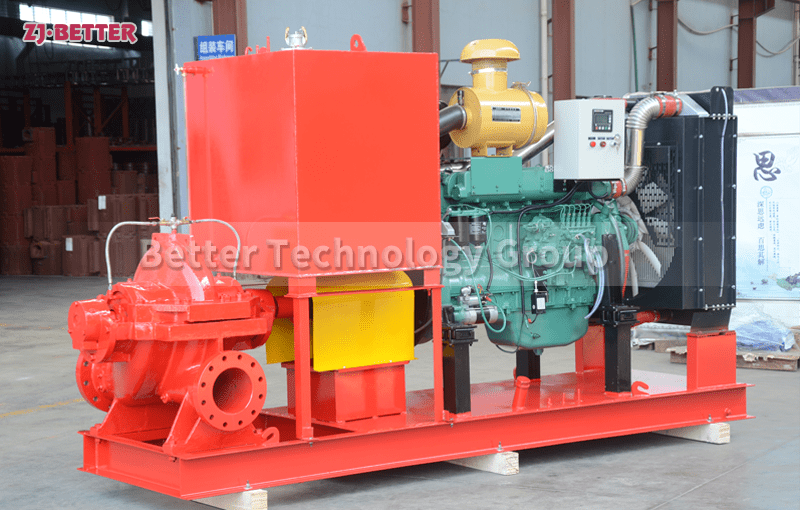

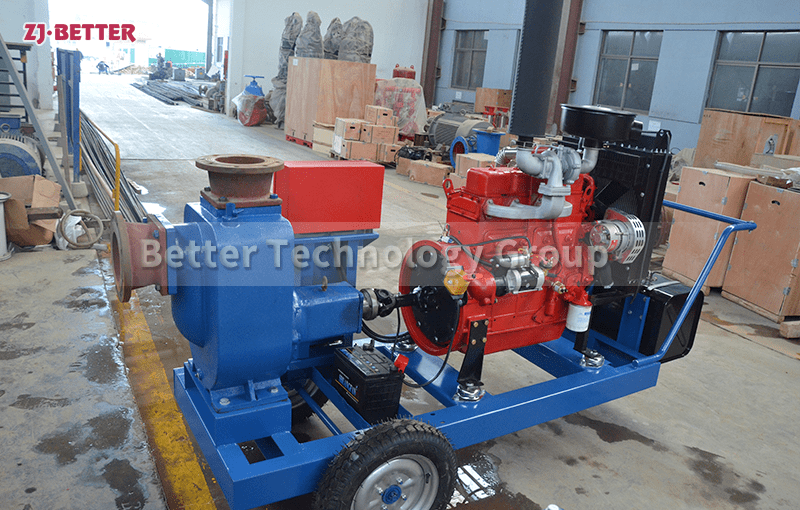

Diesel Fire Pump

The operation of the Fire Pump Set

Operation of diesel engine fire pump

Diesel engine fire pump operation:Start, Stop and Run of the Equipment

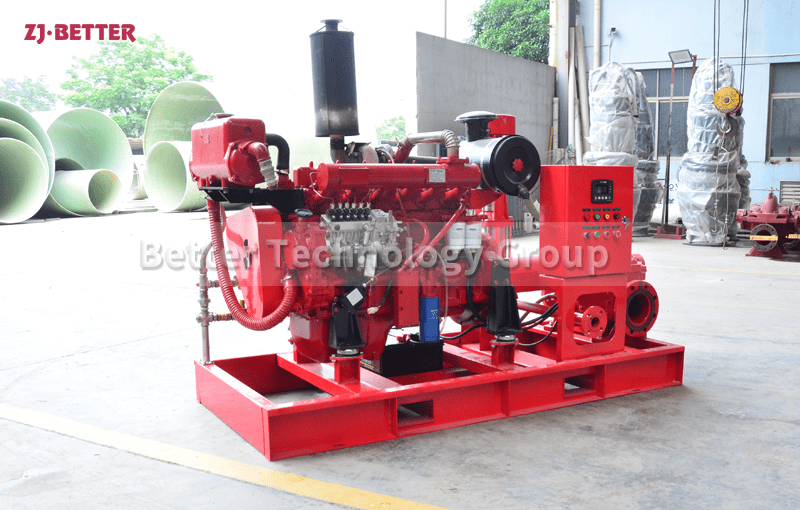

Start: first make sure of the correct rotatingdirection of the fire fighting pump and the inlet valve is as N.O and outletvalve N.C. Before the pipe network starts with no water. After no error is found, start the fire-fighting pump and, when the pump gets stable run, gradually open the outlet valve and adjust it to the work condition point for the pump to run. The outlet valve is N.O. when the network is filled with water at usual.

Run: when the pump gets a normal run, check the shaft seal and the bearing to see how it works. Theleakage for themechanical seal should not be over 3 drops/min and for the stuffing seal should be dot drop. The bearing’s temperature should not be over 75℃ and its temperature rise not over 35℃ Stop running for a checking case of an abnormal sound during the pump’s run.

To stop, first close the outlet valve, then the diesel engine.

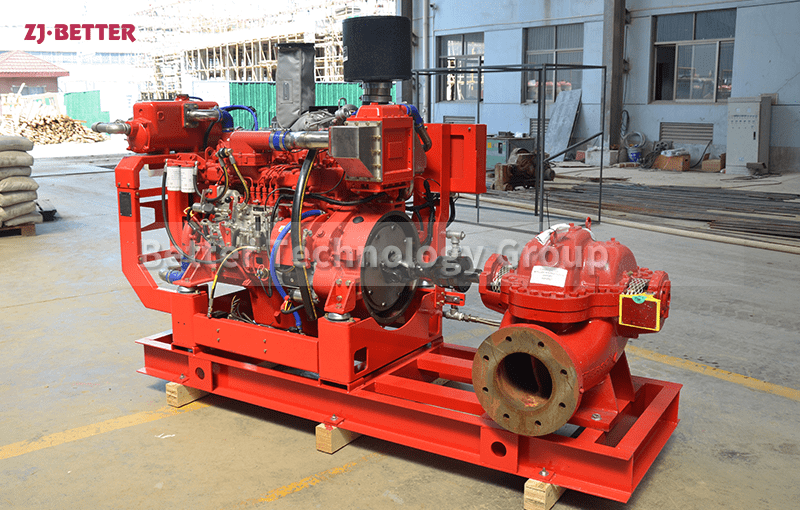

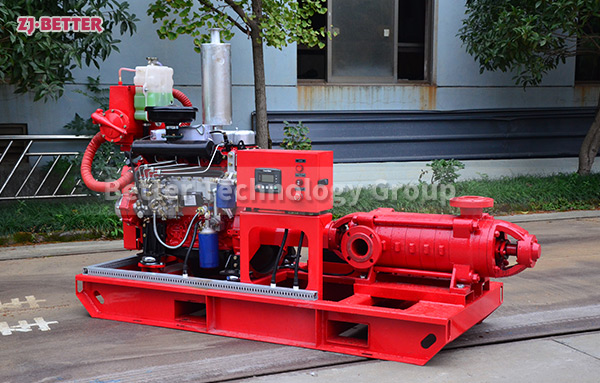

The operation of the Fire Pump Set

Operation of diesel engine fire pump

Diesel engine fire pump operation:Start, Stop and Run of the Equipment

- Start: first make sure of the correct rotatingdirection of the fire fighting pump and the inlet valve is as N.O and outletvalve N.C. Before the pipe network starts with no water. After no error is found, start the fire-fighting pump and, when the pump gets stable run, gradually open the outlet valve and adjust it to the work condition point for the pump to run. The outlet valve is N.O. when the network is filled with water at usual.

- Run: when the pump gets a normal run, check the shaft seal and the bearing to see how it works. Theleakage for themechanical seal should not be over 3 drops/min and for the stuffing seal should be dot drop. The bearing’s temperature should not be over 75℃ and its temperature rise not over 35℃ Stop running for a checking case of an abnormal sound during the pump’s run.

- To stop, first close the outlet valve, then the diesel engine.