How does this fire pump maintain high efficiency under varying load conditions?

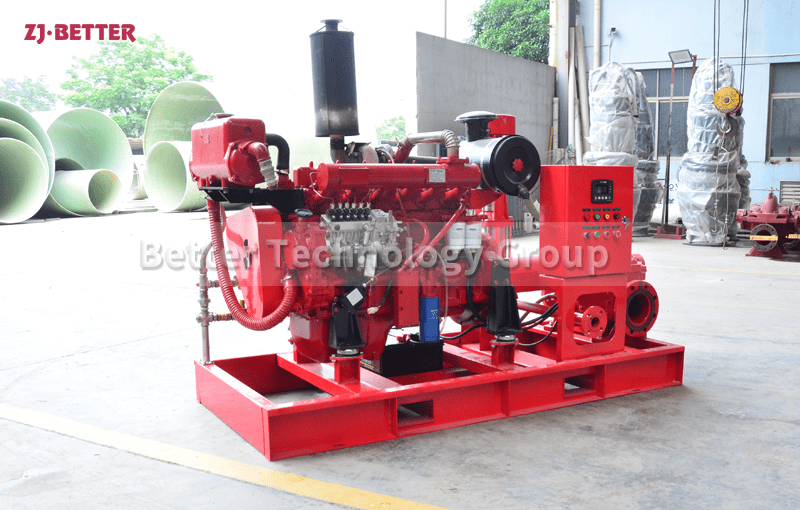

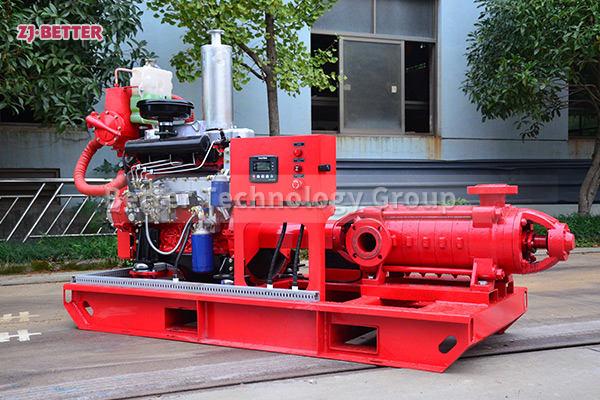

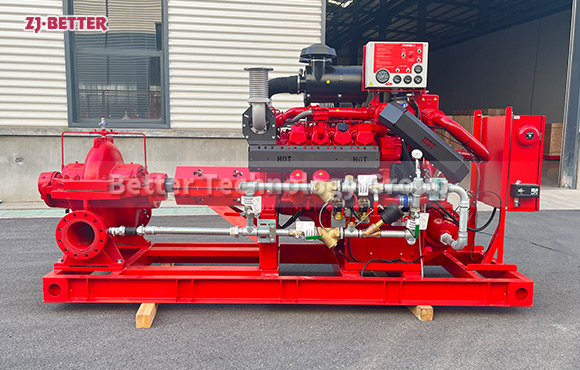

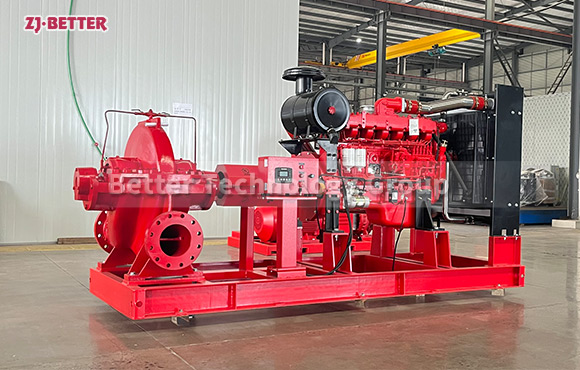

This fire pump is equipped with an advanced intelligent control system, enabling it to operate efficiently under varying load conditions. Whether it’s high-flow demand or high-head requirements, the intelligent control system adjusts the pump’s operation in real-time, ensuring stable water flow and pressure. This not only enhances the fire system’s response speed but also optimizes energy usage, maximizing efficiency and minimizing energy waste. The design of this fire pump emphasizes safety, featuring multiple protective mechanisms such as overload protection and low-water protection, ensuring reliable operation in any scenario. Additionally, its high-temperature and corrosion-resistant materials ensure the pump’s stability and durability in extreme environments, extending the equipment’s lifespan.

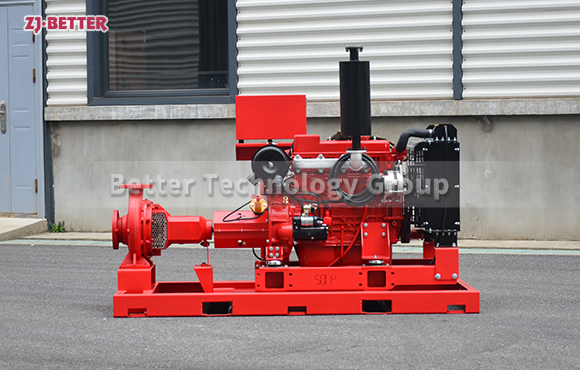

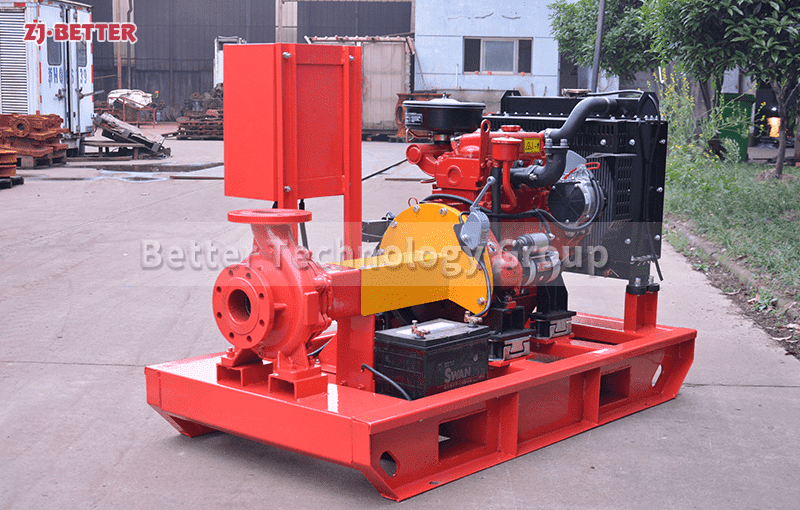

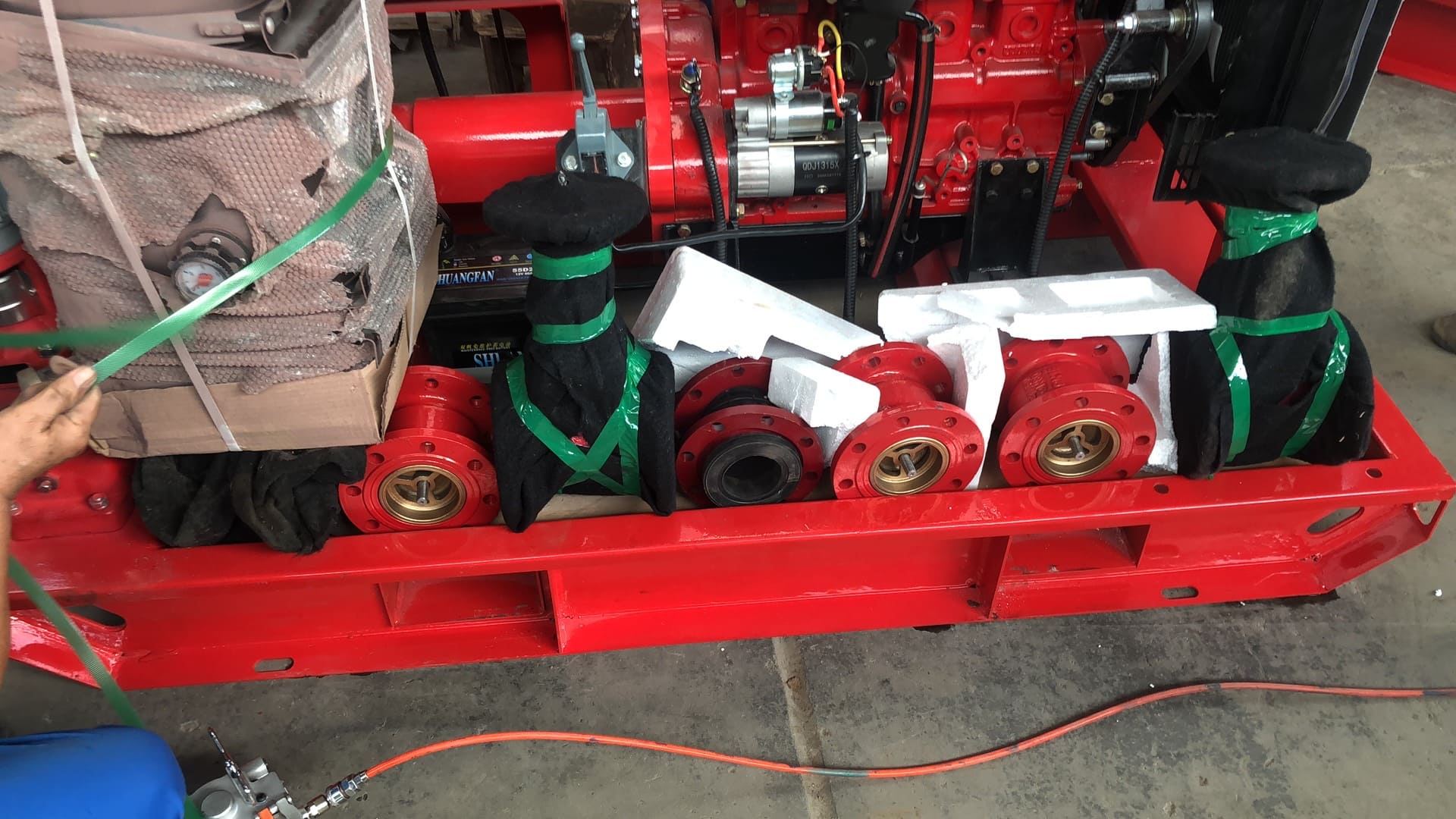

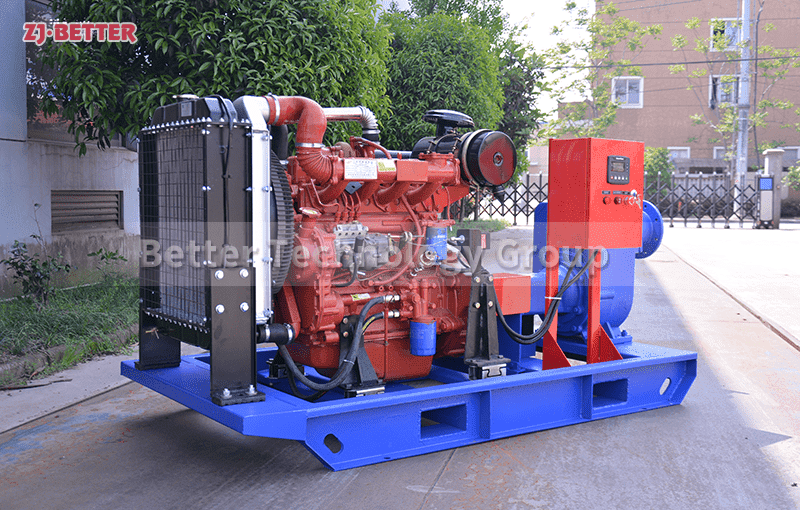

Our company specializes in the research and manufacturing of high-performance fire pumps, dedicated to providing safe, stable, and efficient fire protection equipment for customers worldwide. We offer a wide range of fire pumps, including electric fire pumps, diesel engine fire pumps, and pressure-stabilizing water supply systems, suitable for various building and industrial facility fire protection needs. Each product is designed with advanced hydraulic engineering and high-efficiency power systems to ensure high head, large flow output, meeting the diverse fire safety demands. Our products are equipped with intelligent control systems, enabling automatic start-stop, fault monitoring, and remote monitoring, greatly enhancing the automation and convenience of fire systems. Additionally, the equipment is built with high-temperature and corrosion-resistant materials, ensuring stability and long-term reliability in extreme environments. All products comply with international fire safety standards, widely used in high-rise buildings, industrial parks, and municipal projects, providing comprehensive fire safety solutions to our customers.