No Power, No Problem: Stability and Reliability of Diesel Engine Fire Pumps

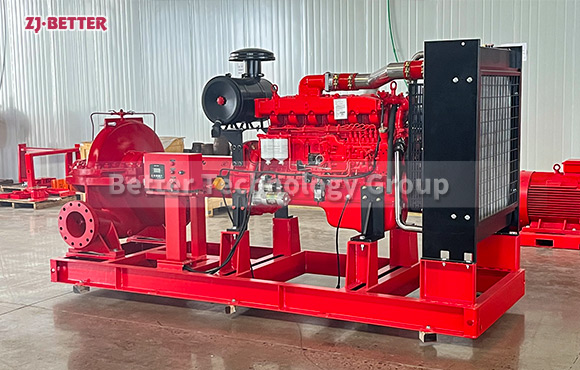

In fire protection systems, a power outage can lead to the failure of the entire system, especially in emergency situations. However, the diesel engine-driven fire pump ensures stable operation even without an external power source, guaranteeing that the fire protection system remains operational in any condition.

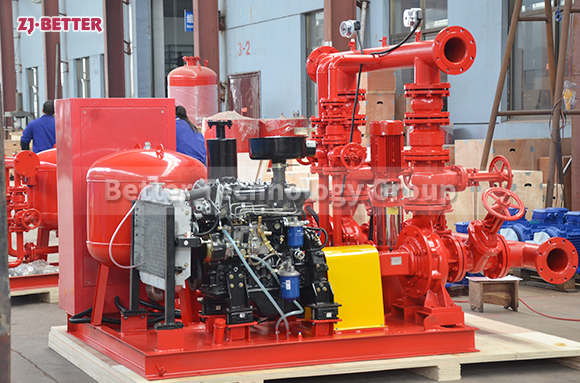

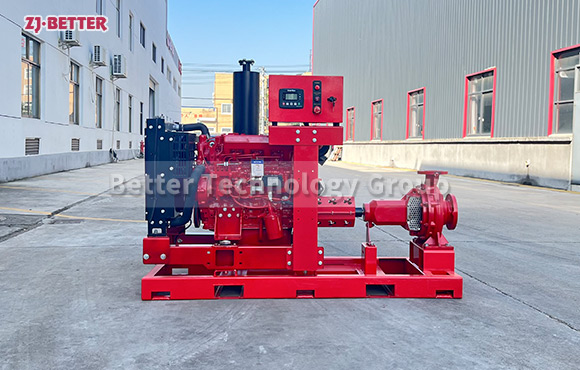

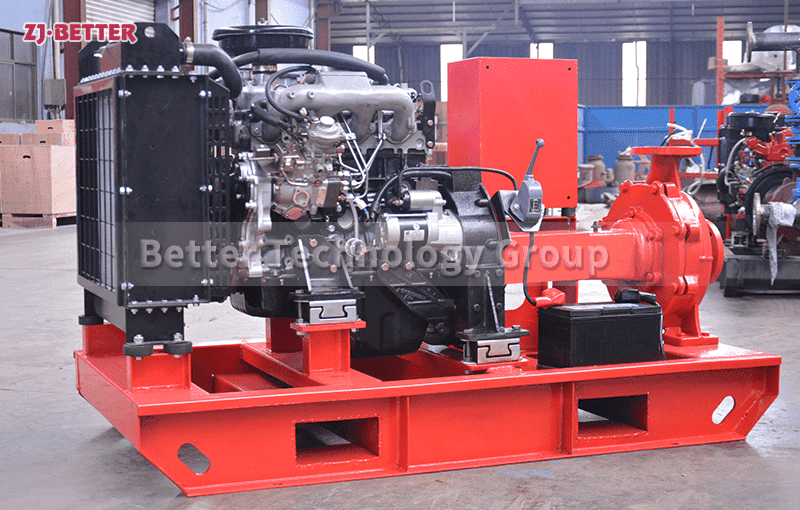

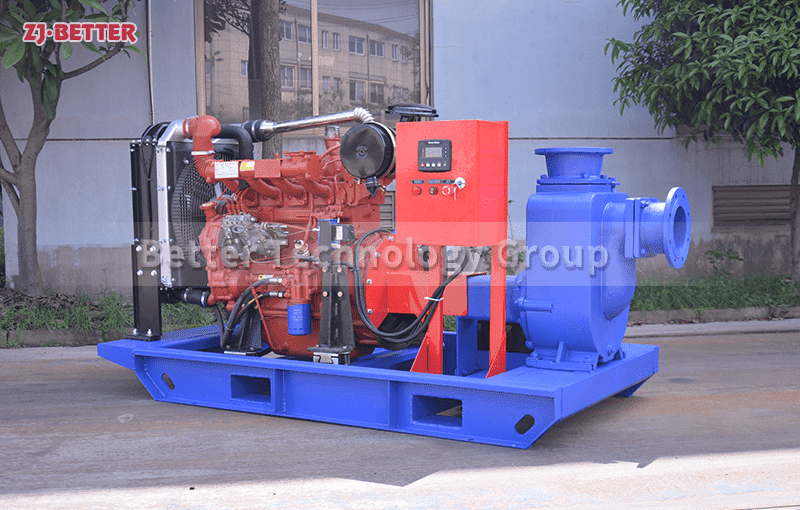

This diesel engine-powered fire pump is the ideal solution to address power supply interruptions, offering high stability and reliability. Whether in high-temperature, humid, or harsh environments, this pump can quickly start up and provide a powerful water flow to combat fires. Its compact design and ease of maintenance make it suitable for buildings and industrial facilities of various sizes.

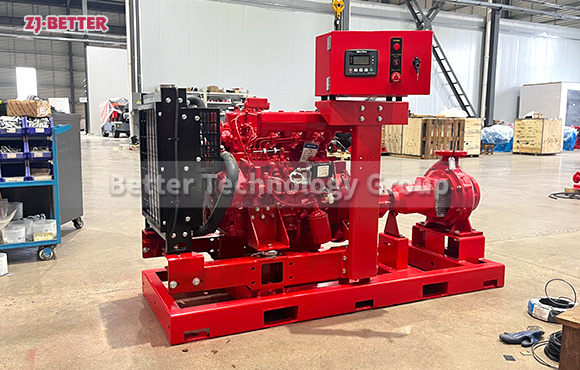

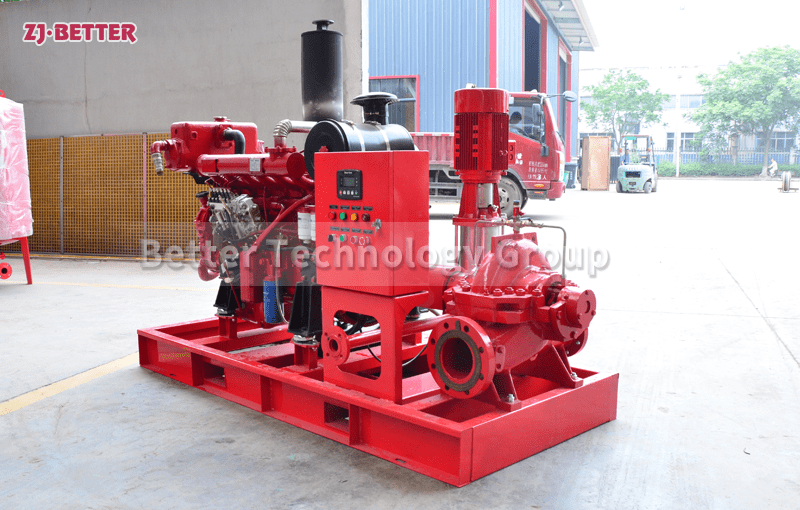

In addition to its outstanding stability, the diesel engine fire pump features automatic start and stop functions, ensuring a quick response in emergencies and reducing the complexity of manual operations. With an intelligent control system, the pump continuously monitors its operational status and automatically triggers alarms in case of any anomalies, ensuring the safety and efficiency of the fire protection system.

Whether for industrial parks, high-rise buildings, or other high-risk areas, this diesel engine fire pump provides robust fire prevention capabilities to protect vital assets.

The company specializes in the research, development, manufacturing, and supply of fire pumps and related systems, committed to providing efficient and reliable fire protection solutions to the global market. With years of industry experience and technological expertise, our products span diesel engine-driven fire pumps, electric fire pumps, and water treatment equipment, widely used in industries such as construction, manufacturing, petrochemical, and mining.

Our fire pump systems are designed with advanced technology and high-quality materials, ensuring they perform reliably and efficiently even under extreme conditions like high temperatures and pressure. Whether during power outages or in harsh environments, our diesel engine-driven fire pumps can respond quickly and provide stable water flow, ensuring the success of emergency firefighting operations.

Moreover, our products incorporate intelligent control systems, making operation easier and enhancing the safety and reliability of the equipment with real-time monitoring. The company offers customized solutions and designs according to customer needs, catering to fire protection requirements in different application scenarios.

As a leader in the fire protection equipment industry, we continuously drive technological innovation and improve product performance, ensuring that customers receive optimal protection during any fire incident.