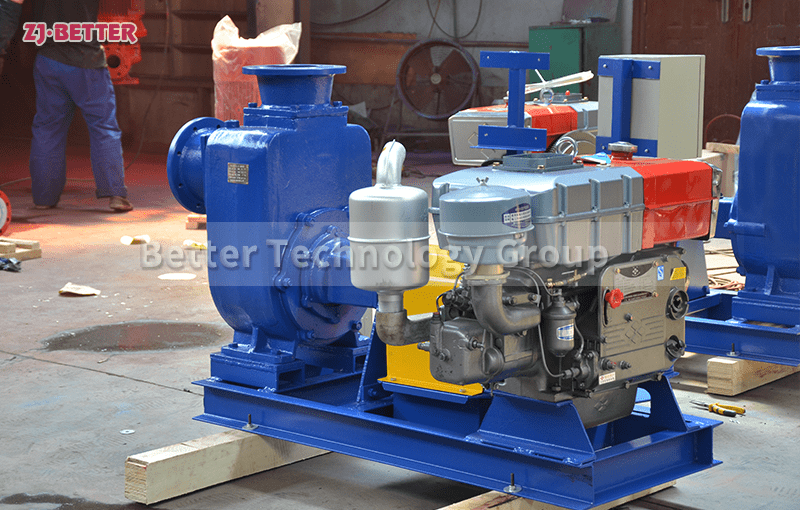

Self priming irrigation pump

Self priming irrigation pump, the whole pump body is light and can be moved by one person. It is simple to install and can be used for pumping irrigation immediately. Centrifugal self-priming principle is adopted. Water or liquid is pumped into the diesel engine to form kinetic energy and generate energy to complete the work.

Recalling the past look to the future

In 2004Set up pump factory in Wenzhou.

Shanghai Xizhiquan Pump & Valve Co, LTD. was established.

In 2005The sales turnover exceeded 20 million yuan.

In 2006Establish technology cooperation with Korea Xiandai pump Corp. and Japanese famous pump & valve Company.

In 2006The distributors from around China visited our factory.

In 2007Cooperate with Chinese famous B2B platform, and establish Chinese website.

In 2008Move the factory from Wenzhou to Quzhou.

Set up a subsidiary corporation: Quzhou Better Explosion-proof Motor Co.,Ltd.

Independently develop Air Top Fire fighting water supply equipment.

In 2009Set up a subsidiary corporation, mainly product: valves.

In 2010Move the factory to Hangbu Economic Development Zone, and expand to 20000 square meters Establish famous international B2B website.

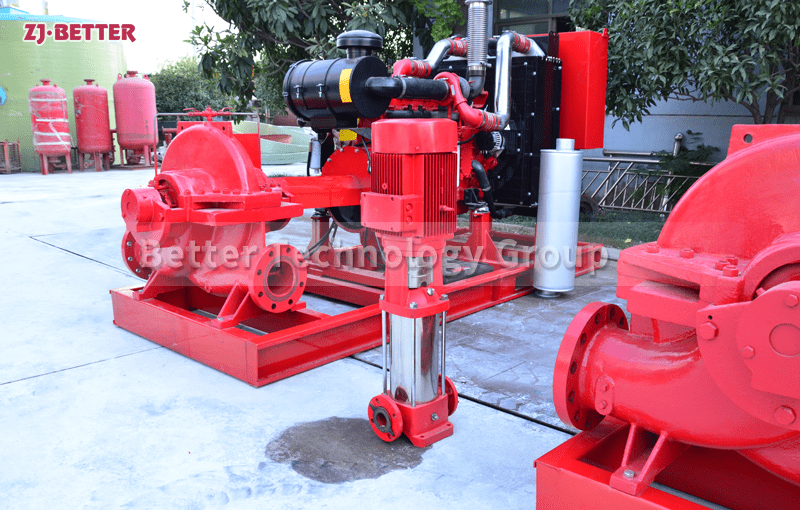

In 2013Independently develop EDJ fire pump system, and well known by domestic and international customers.

In 2014Independently develop fire emergency pump truck and sell to market.

In 2015Research and development of air conditioning pump together with the Zhejiang University of Technology.