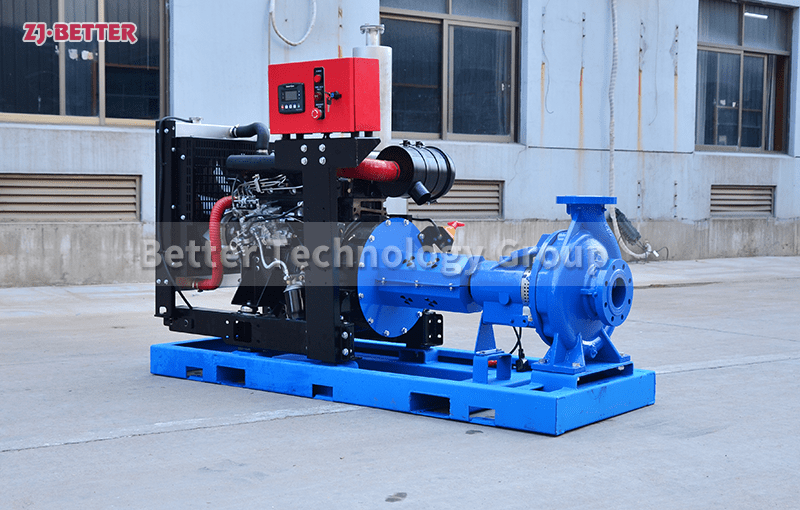

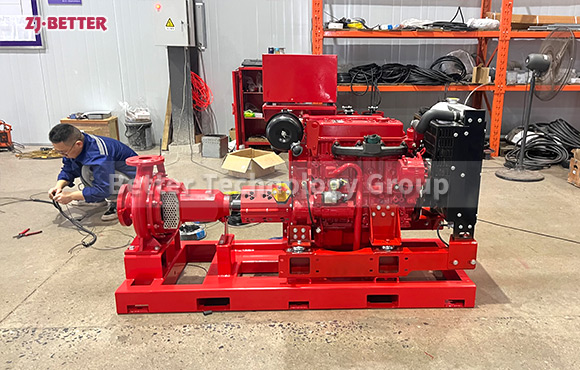

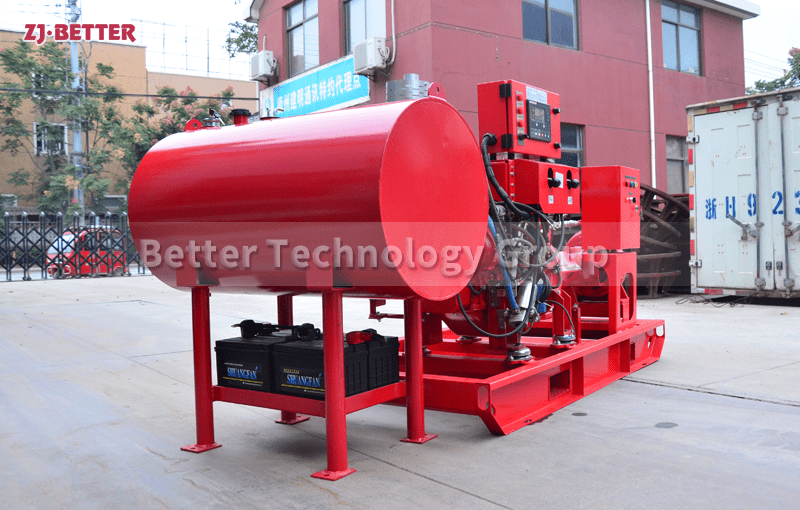

Fire pump – XBC-IS diesel fire pump for emergency situations

Fire pump systems are also suitable for other emergency and backup applications:

Hotels, hospitals, gymnasiums and other public places;

Chemical, oil refining, metallurgy, energy, pharmaceutical and military enterprises;

Shopping malls, similar to Wanda Complex;

Office buildings, high-end residences;

Better (China) Technology Co., Ltd. is a diesel-driven fire pump designed and manufactured according to GB6245-2006 fire pump. Meet the latest certification CCCF requirements and obtain a certificate. The advantage of this product is that when there is a fire, power failure, or the electric fire pump cannot work normally, the diesel fire pump will be automatically put into operation to ensure the normal firefighting; secondly, compared with the advantages of the electric fire pump, the diesel engine pump does not require long-term investment in power supply , saving power transformers and normal expenses. The diesel fire pump is equipped with various automation functions to meet the requirements of national standards to ensure that the equipment is in normal standby for a long time and is ready to work at any time.