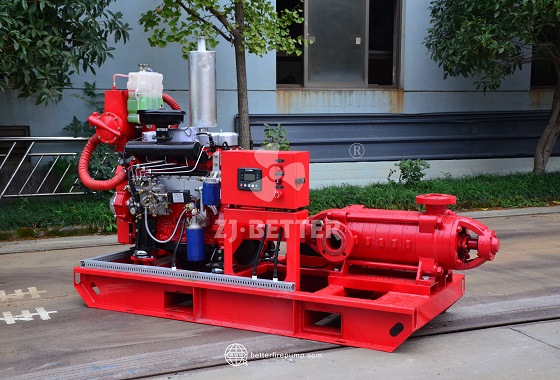

XBC Diesel Fire Pump – Made in Better Factory

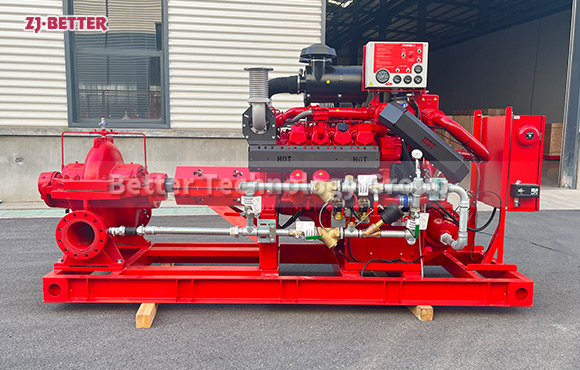

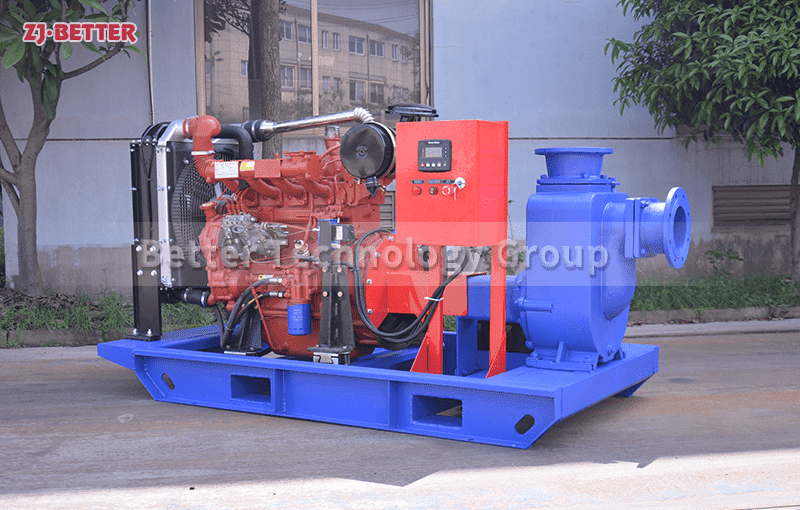

Overview of diesel engine fire pump products: The fire pumps used in the complete diesel engine fire pump unit can be the IS series single-stage type, S series new single-stage two-stage type, and D type series segment multi-stage type produced by our company. The diesel water pumps used in this series of equipment are made of domestic high-quality products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, convenient maintenance, simple use and high degree of automation. They are advanced and reliable fire fighting equipment.

XBC basic unit consists of diesel engine, chassis, cooling refrigerator and fan, high elastic coupling, water pump, diesel tank and control panel and other equipment. The water pump is directly connected with the diesel engine through a highly elastic coupling or a diaphragm coupling, and is jointly installed on the common channel steel chassis.

Cooling of the engine The cooling water tank is cooled by the engine-driven fan. The entire cooling system forms a closed loop, and the water tank is also installed on the chassis. The control panel and the unit are separated, and the two are connected by control cables, signal cables and power cables. The fuel tank of the unit with diesel engine power below 200kw is directly installed on the unit, and the unit greater than 200kW adopts the split fuel tank. The basic unit is suitable for fire protection systems with an inverted water source.

.jpg)