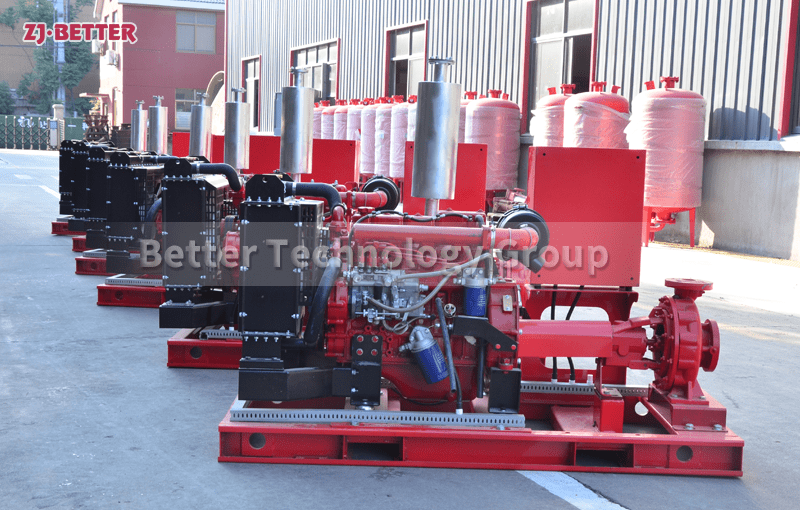

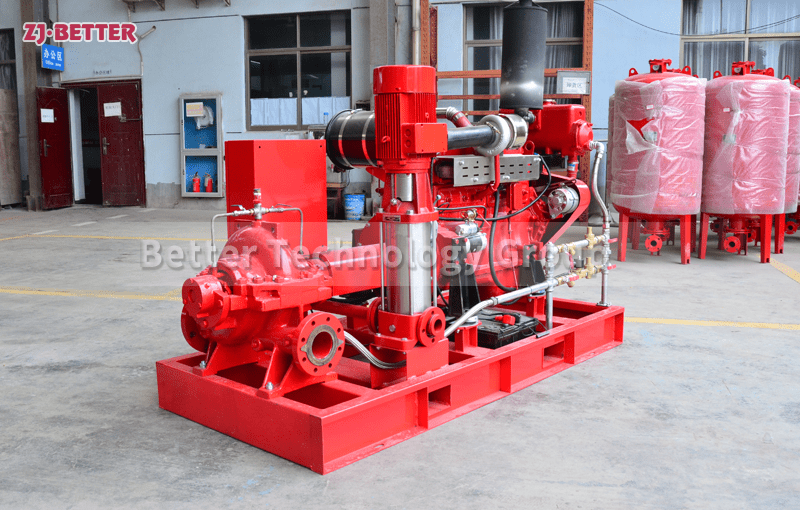

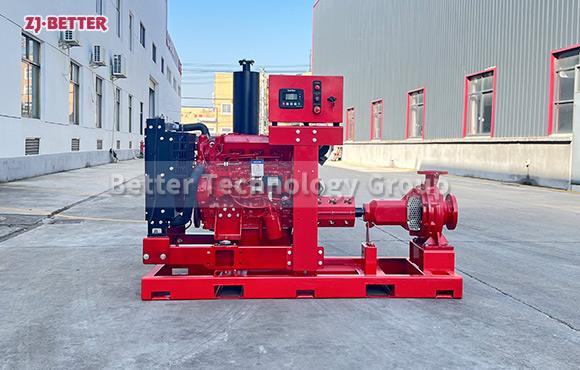

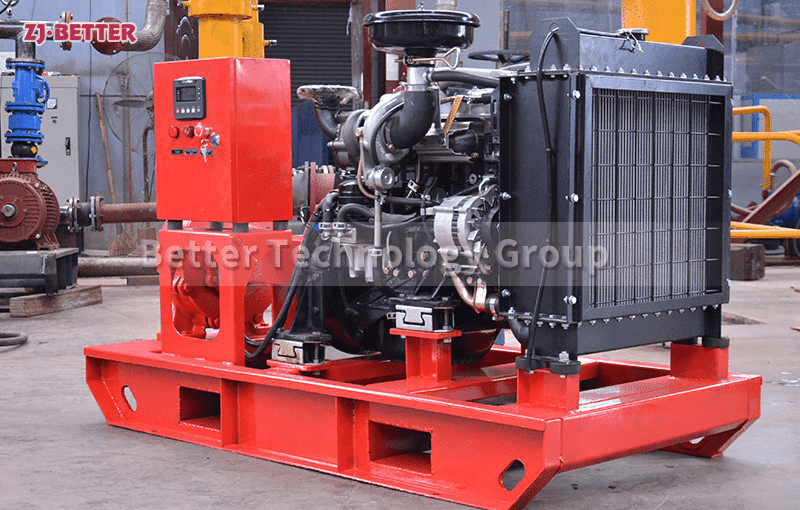

Seven main uses of diesel engine fire pump

Diesel engine fire pump has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. This diesel engine pump set can transport clean water or other liquids whose physical and chemical properties are similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump’s flow parts, sealing form and adding a cooling system.

1. Industry

Boiler feed water system, cooling circulation system

2. Smelting

Water supply circulation system, cooling circulation system

3. Fire protection

Fire hydrant system, sprinkler system, spray cooling system, foam system, water cannon system

4. Military aspects

Field water supply system, island fresh water collection system

5. Heating

Water supply circulation system, cooling circulation system

6. Municipal aspects

Emergency drainage, emergency water supply

7. Agriculture

Drainage and irrigation system