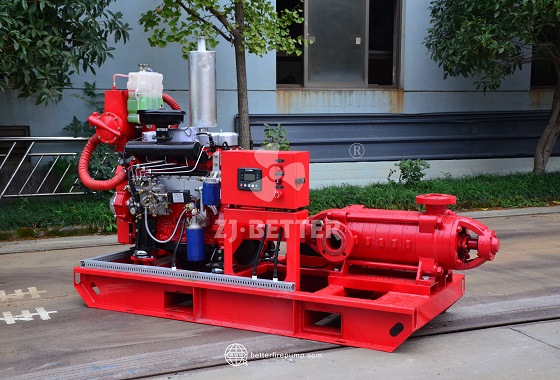

Horizontal Diesel Engine Fire Pump – Reliable High-Head Solution for Firefighting Systems

This article introduces a horizontal diesel-driven multistage fire pump, highlighting its reliability and advantages in high-pressure water supply systems. Designed with a multistage centrifugal structure and diesel engine drive, it is ideal for high-rise buildings, industrial facilities, and remote firefighting scenarios. Key benefits include high head output, independent operation, intelligent controls, safety protection, efficient multistage impellers, and corrosion-resistant materials. The unit supports modular installation and customized design and meets international standards such as UL/FM, making it an essential component in modern firefighting infrastructure.

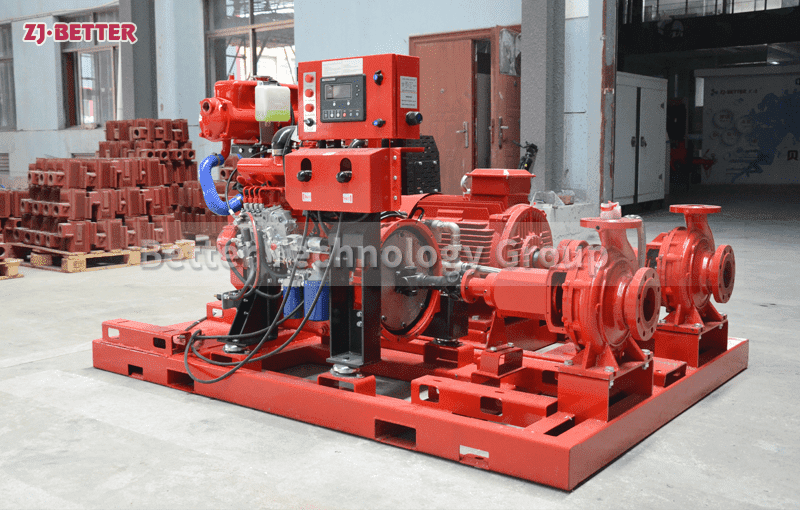

In modern urban and industrial safety systems, fire pumps must deliver high pressure, reliable performance, and rapid response. The horizontal diesel-driven multistage fire pump offers robust high-pressure output and independent power, making it the ideal choice for high-rise buildings, petrochemical sites, power stations, and long-distance water supply systems.

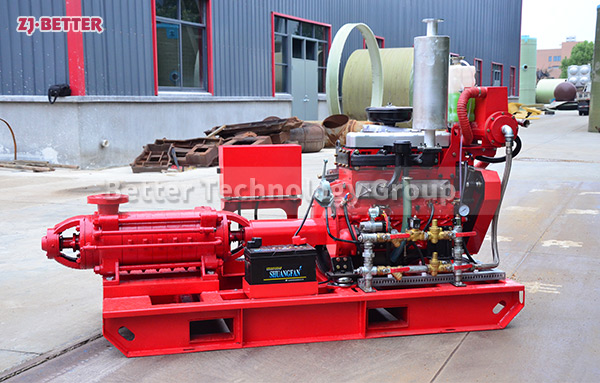

1. High Head Output for Complex Scenarios

With a multistage centrifugal pump design, it delivers steady and continuous high-pressure water output, capable of reaching heads over 200 meters, making it perfect for high-rises, remote industrial zones, and extended piping systems.

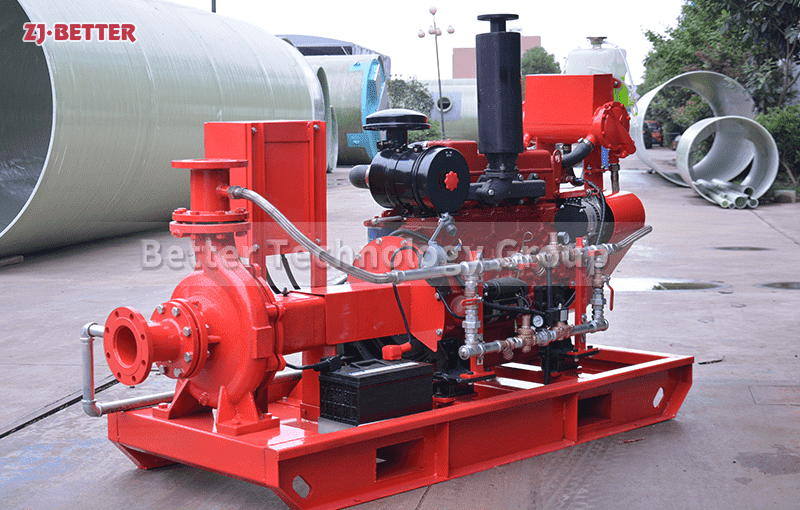

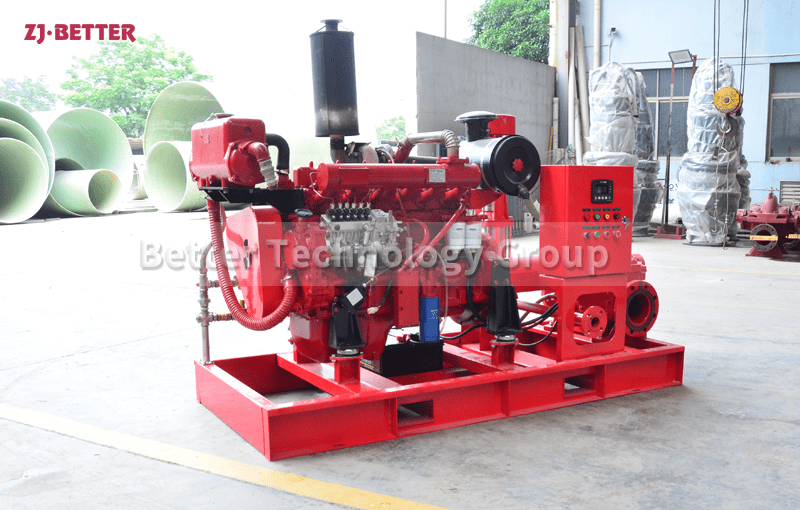

2. Powerful Diesel Engine for Independent Operation

Equipped with globally recognized engines like Cummins, Deutz, or Perkins, these pump sets ensure reliable operation even in power outage scenarios, offering vital protection for critical areas.

3. Horizontal Structure for Smooth Running

The horizontal configuration ensures better balance and lower vibration, providing quieter and more stable operation. It’s suitable for both indoor and outdoor installations and is easy to maintain.

4. Multistage Impellers for Enhanced Efficiency

The pump uses multiple impellers in series to progressively boost water pressure, ensuring consistent and powerful delivery even to high elevations or long-distance pipelines.

5. Smart Control Panel for Easy Operation

Integrated with a user-friendly intelligent control system, featuring one-button start, auto-switching, fault alarms, and real-time monitoring to maximize system efficiency and operator convenience.

6. Multi-Level Safety Protection

Includes automatic protection for over-temperature, overload, low oil pressure, and high coolant temperature, ensuring safe operation under harsh or emergency conditions.

7. Modular Base for Quick Installation

Pre-installed on a solid steel skid, the complete unit offers compact structure and ease of transport. Installation is quick—just connect the pipework and power system.

8. UL/FM Compatibility for Export Markets

Available in UL/FM-compliant designs to meet North American and Middle Eastern fire safety standards, these pump sets are widely exported and globally trusted.

9. Corrosion-Resistant Materials for Harsh Conditions

Key components are made from stainless steel or ductile iron for superior resistance to corrosion and wear, ensuring long-term performance in humid, hot, or marine environments.

10. Customizable to Project Needs

Flexible in configuration to meet specific flow, head, and layout requirements. Custom options include engine brands, pump models, and control systems for a tailored firefighting solution.

The horizontal diesel engine multistage fire pump stands out as a reliable and versatile choice for firefighting water supply systems. With its powerful performance, flexible installation, and international compatibility, it provides essential safety assurance for both new projects and retrofitted systems.