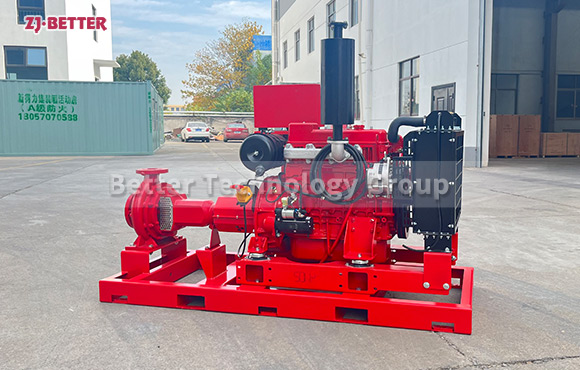

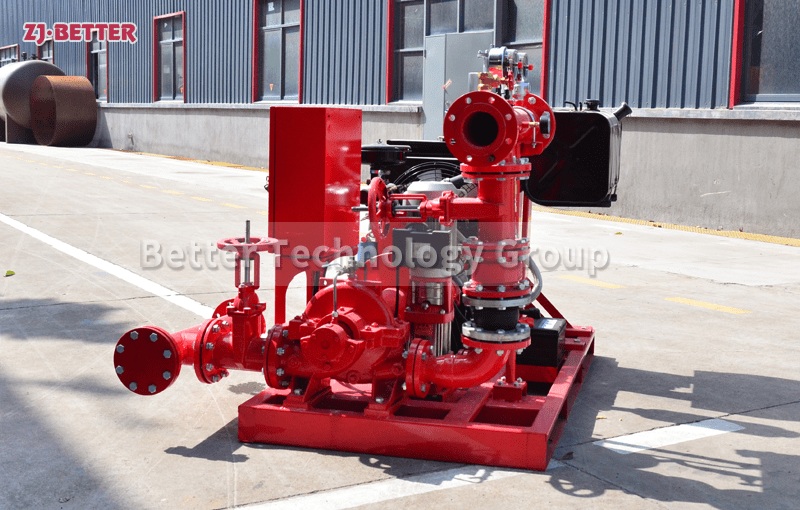

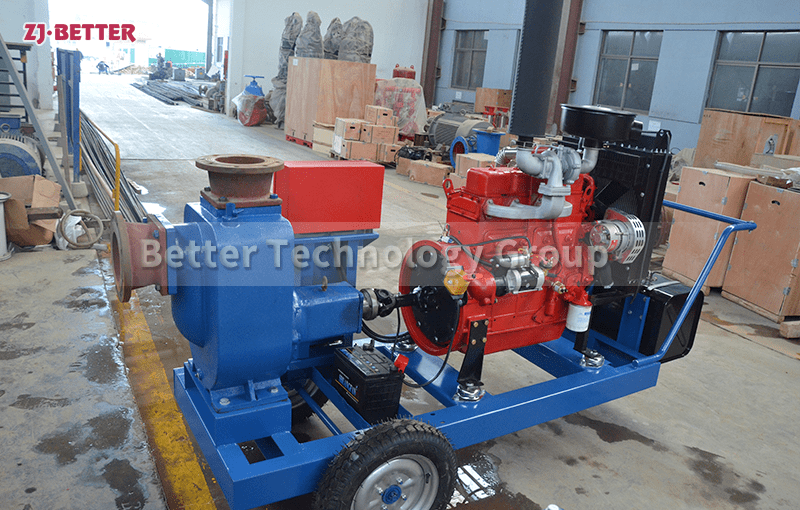

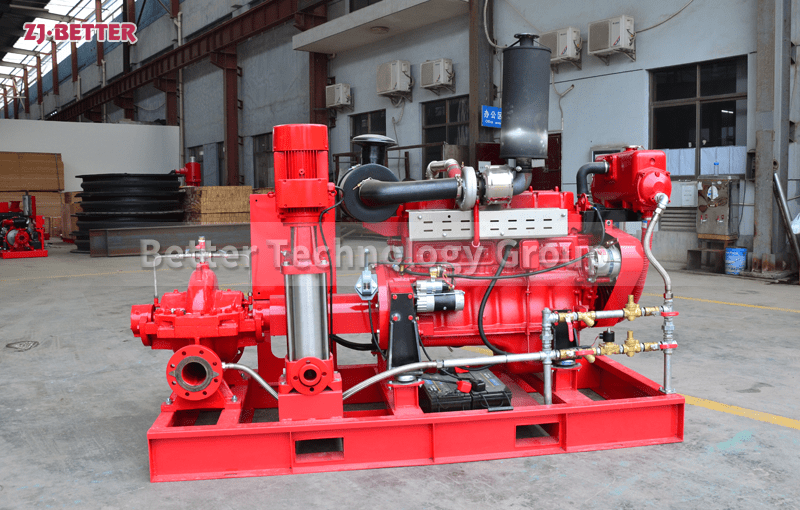

End Suction Diesel Fire Pump for Industrial and Commercial Fire Safety

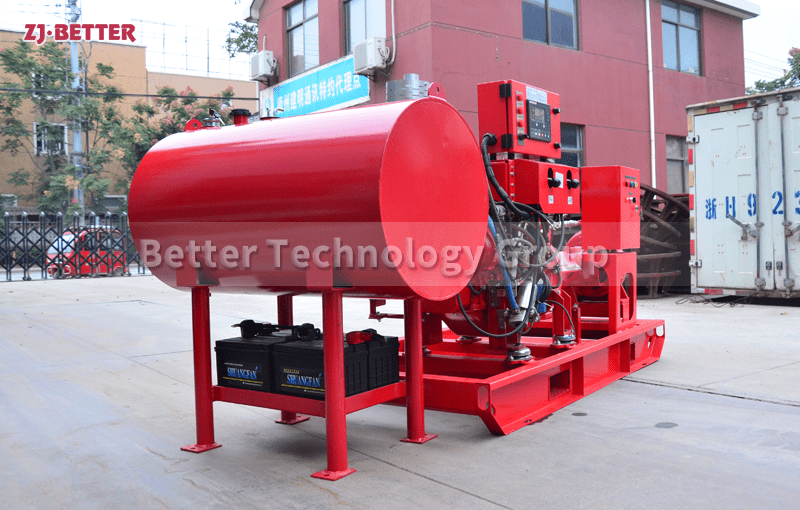

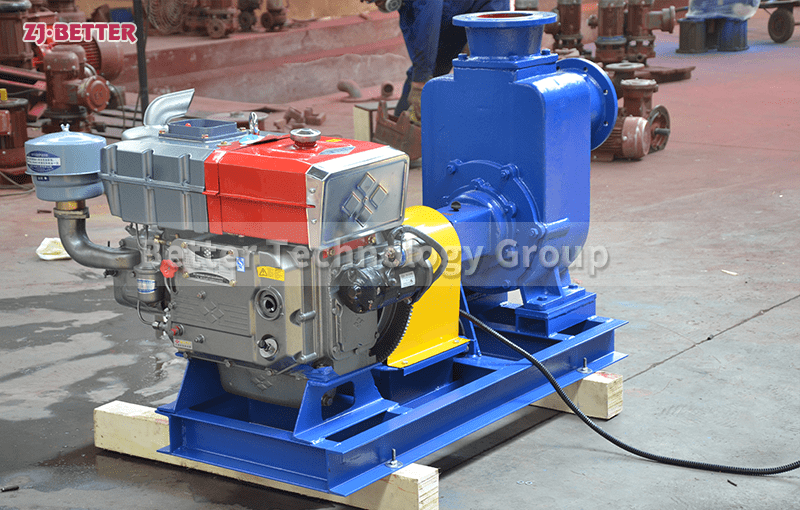

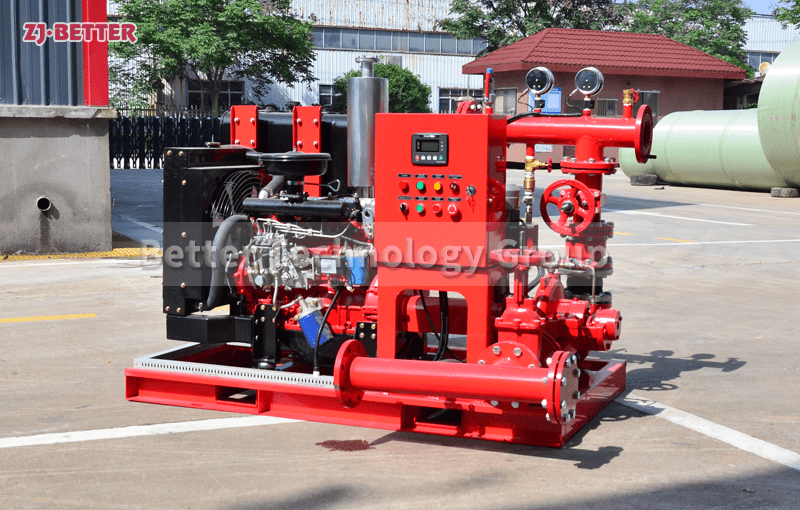

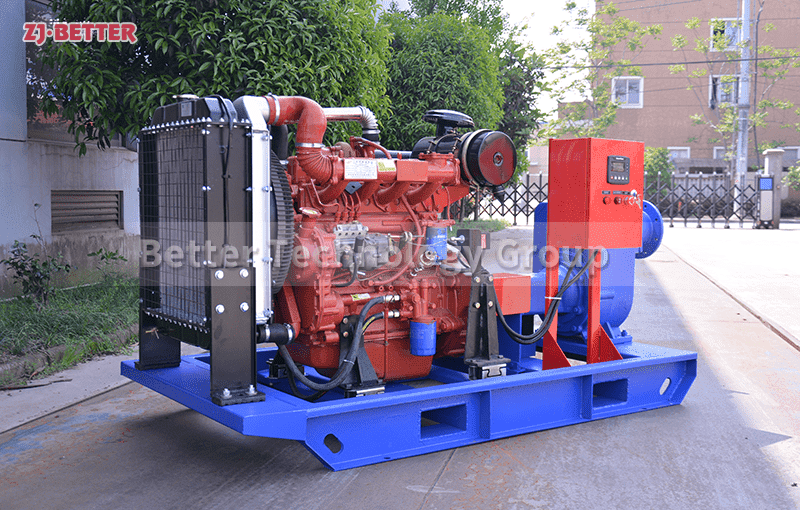

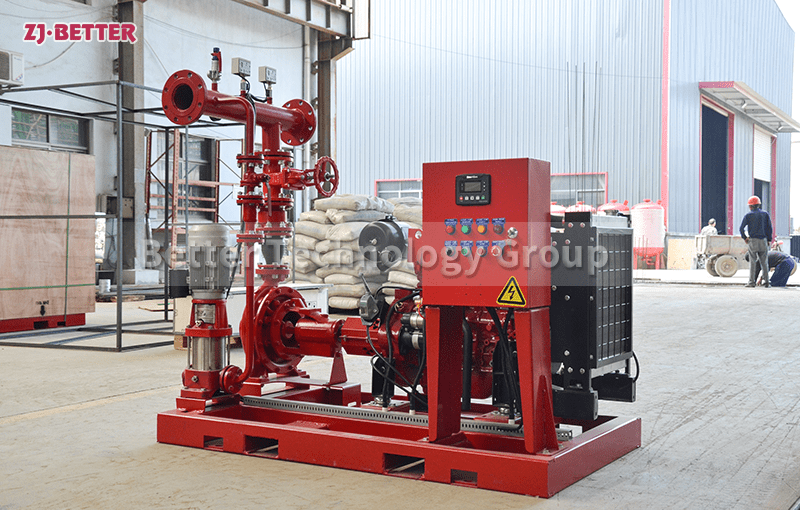

This end suction diesel fire pump is purpose-built for industrial and large-scale commercial fire protection, delivering rapid start-up performance and consistent high-pressure water output. Powered by a heavy-duty diesel engine and paired with a hydraulically optimized end suction centrifugal pump, this unit ensures reliable water supply at critical moments, even in power-deficient environments.

Widely used in petrochemical plants, power stations, logistics centers, and high-rise buildings, this pump is ideal for facilities where electrical power may be unstable or unavailable. The modular design makes installation quick and maintenance cost-effective. It can operate independently or be integrated into a full fire pump set with electric and jockey pumps, all in compliance with NFPA20 and other international standards.

Choosing this diesel-driven end suction fire pump is not just a fire protection upgrade—it’s a commitment to operational efficiency and safety reliability.

We are a modern enterprise specializing in fire pumps and integrated fire protection systems, with over a decade of experience in the industry. Our mission is to deliver premium-quality firefighting solutions to clients around the world. Our product range includes electric fire pumps, diesel engine-driven fire pumps, jockey pumps, controller panels, test & inspection cabinets, full fire pump sets, and UL/FM approved systems. All our products are designed and manufactured in compliance with international standards such as NFPA 20, EN12845, and GB to meet the varying needs of different projects.

On the manufacturing front, we operate with advanced CNC equipment, automated production lines, and a rigorous quality control system. From raw material inspection to precision machining, assembly, and comprehensive testing, we ensure that every unit delivered is 100% qualified. Our in-house R&D center continuously drives innovation by upgrading our products to be more intelligent, modular, and multifunctional. Whether for high-rise buildings, industrial parks, power stations, or transportation hubs, we provide reliable, efficient, and tailor-made fire pump solutions.

When it comes to service, we go beyond product supply. We provide a full suite of support—from system design and product selection to installation guidance and after-sales service. Our experienced international trade team is well-versed in certification requirements and global logistics, enabling us to ship smoothly to the Middle East, Southeast Asia, Africa, Europe, the Americas, and beyond. Our products have earned a solid reputation for quality and performance in a variety of international markets.

Partnering with us means more than purchasing equipment—it’s gaining a trusted fire protection solution provider committed to safety and excellence. We believe that professionalism builds quality, and service shapes the future.