Home » Diesel engine fire pump » Diesel Engine Open Pump Supplier

Content

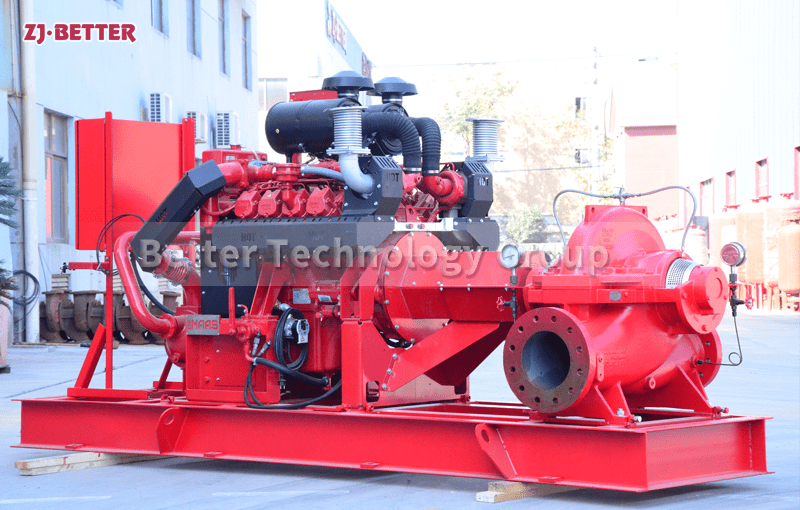

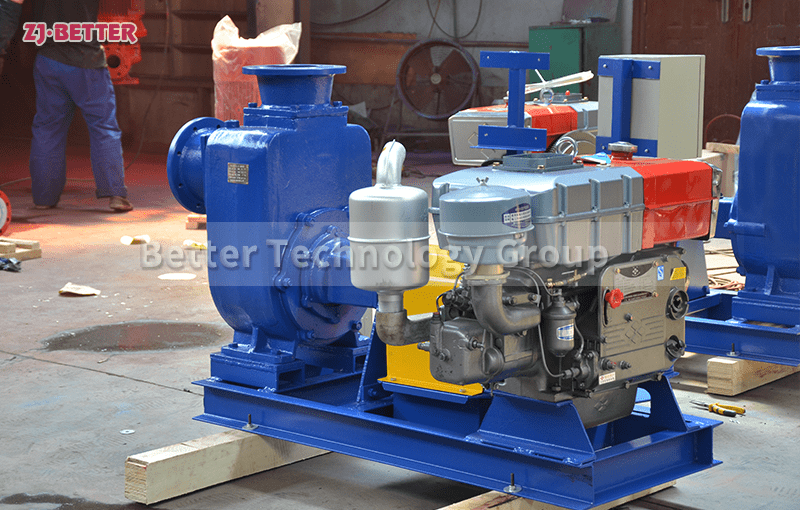

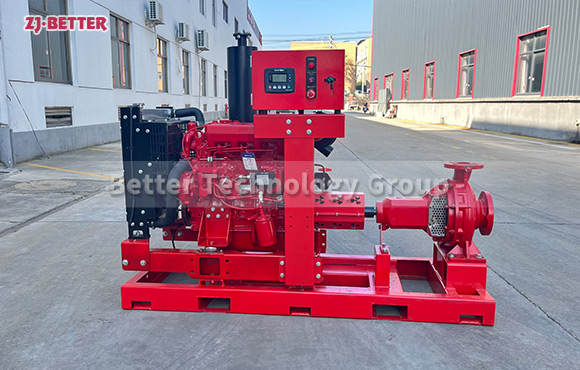

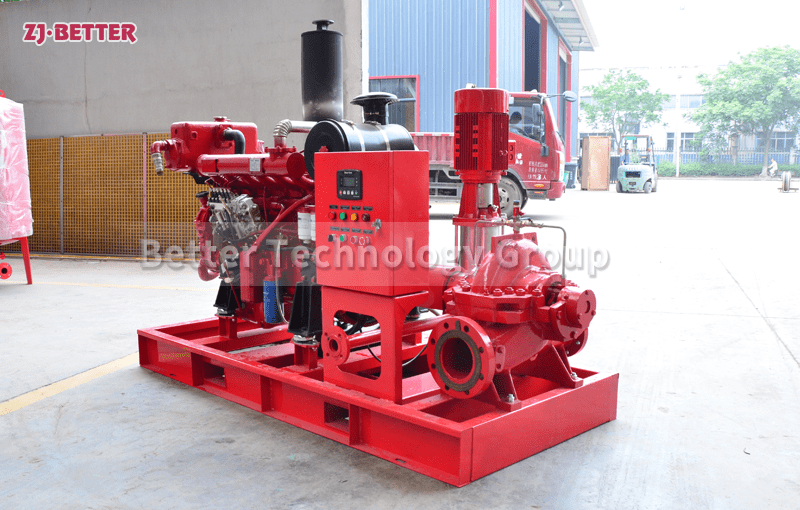

The purpose of diesel engine fire pump is to transport clean water or other liquids with physical and chemical properties similar to water. It is mainly used for pressurization and water delivery in fire protection systems. It can also be used in waterworks, irrigation, drainage pumping stations, power stations, air conditioning circulating water, and industrial water supply systems. , fire protection system, shipbuilding industry, oil refining system, mining and other occasions for transporting liquids.

Inquiry

More Diesel engine fire pump