Diesel Fire Pump for High Temperature and High Pressure Environments: Powerful Performance for Fire Safety

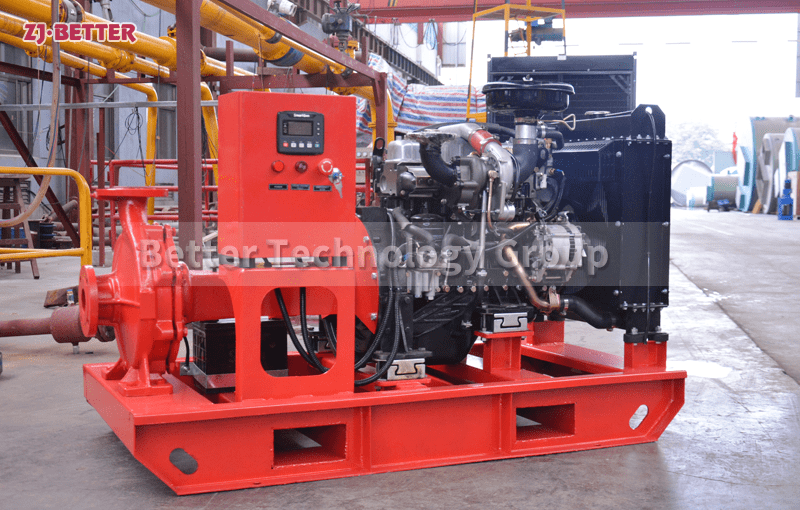

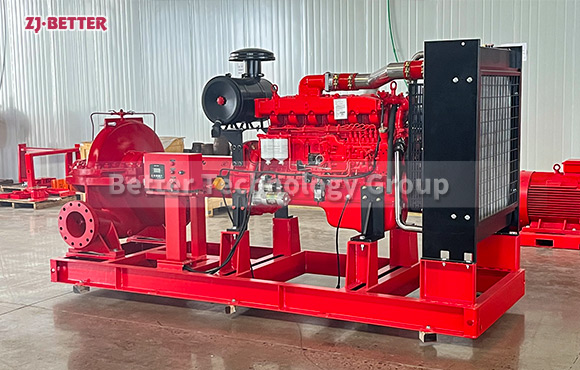

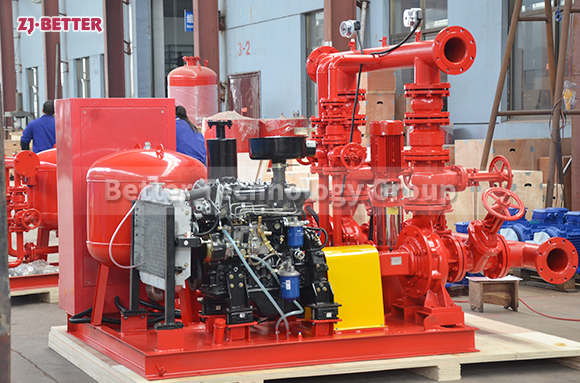

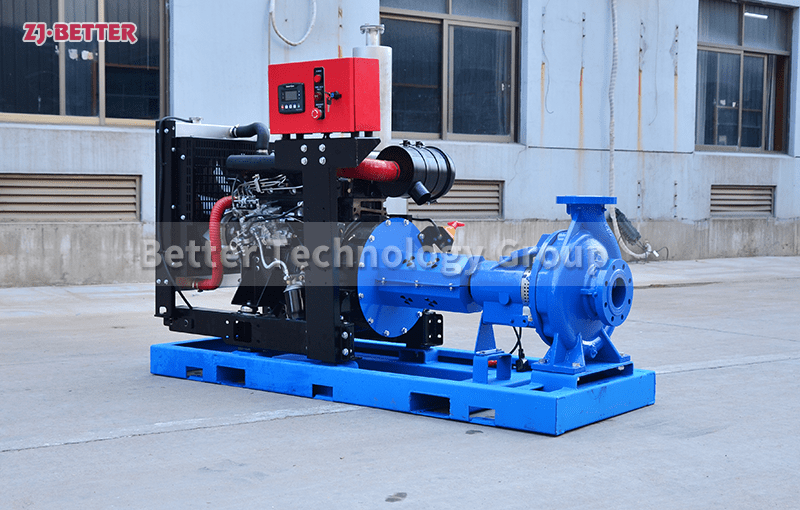

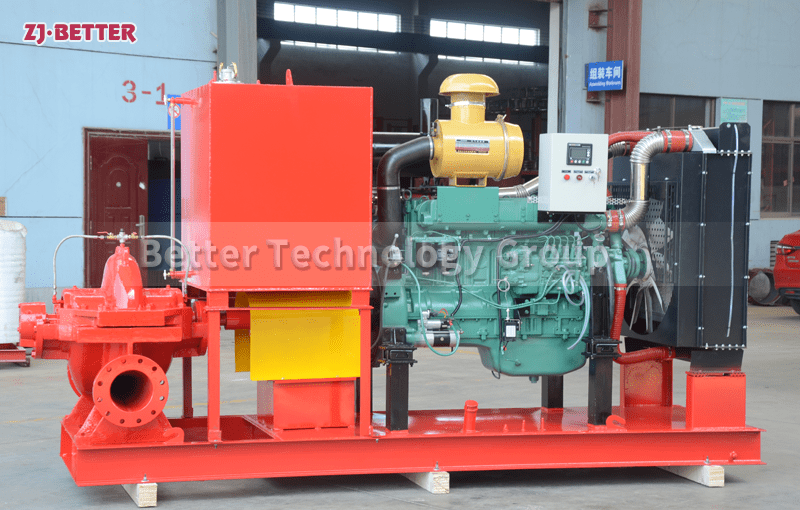

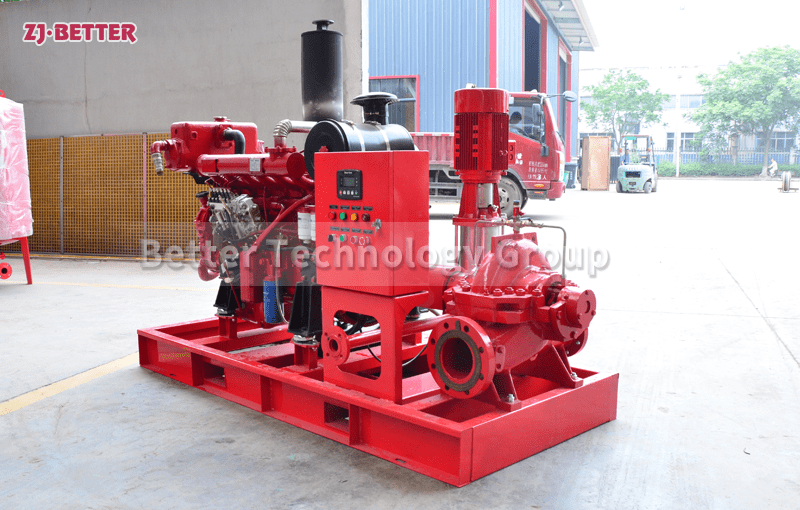

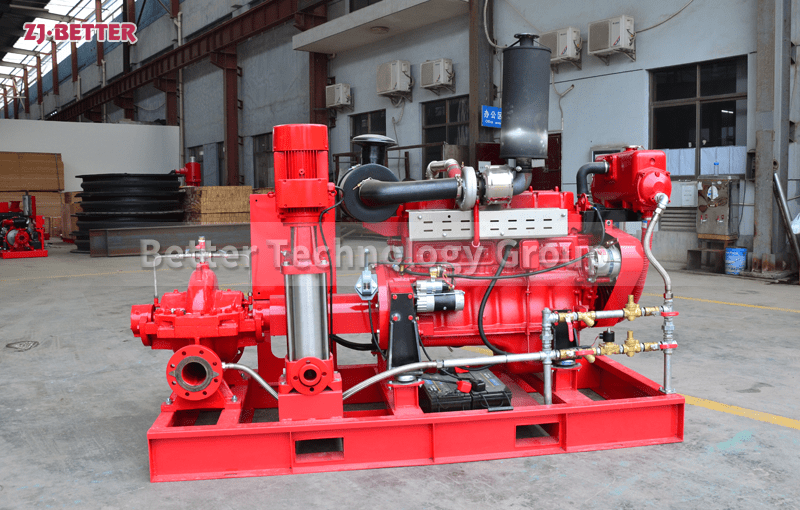

Fire pumps need to operate efficiently and reliably in high-temperature or high-pressure environments to effectively tackle emergency fire situations. Our diesel fire pump system is specifically designed for these extreme conditions, offering powerful performance and excellent resistance to high temperature and pressure, making it an essential component in modern fire protection systems.

This diesel engine-driven fire pump provides a continuous and stable water supply, maintaining outstanding operational efficiency even in high-temperature or high-pressure conditions. The design combines a high-performance engine with an intelligent control system to ensure that the pump starts quickly and maintains a stable water flow during a fire, meeting the demand for high flow and high-pressure firefighting.

Additionally, the diesel fire pump is made with high-temperature and corrosion-resistant materials, ensuring it performs efficiently even in harsh environments. Whether it’s an industrial park, a high-rise building, or a high-risk petrochemical facility, this fire pump offers robust fire prevention capabilities to protect critical infrastructure.

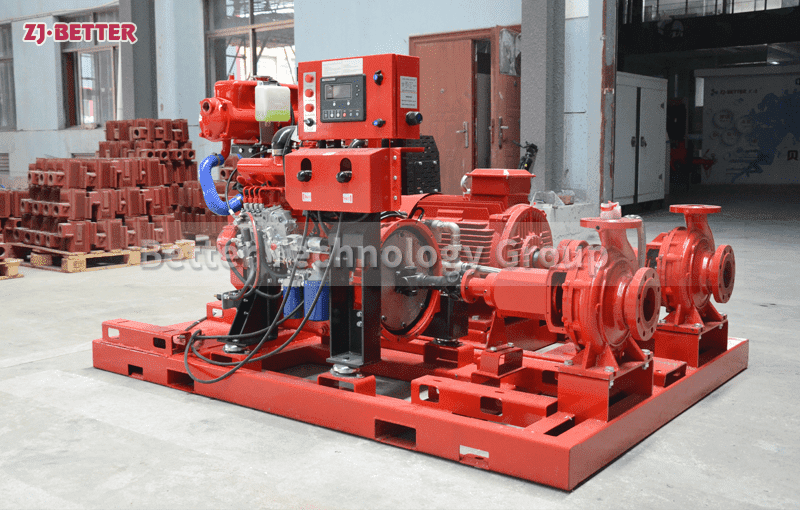

The company specializes in providing high-performance, reliable fire pump systems for the global market, committed to advancing technological progress and innovation in fire protection equipment. Our range of products includes various types of fire pump systems such as diesel engine-driven fire pumps, electric fire pumps, and pressure stabilization systems. Whether in industrial settings, commercial buildings, or petrochemical and large infrastructure projects, our products deliver exceptional fire safety solutions to our clients.

Our product designs adhere to the highest standards and employ advanced manufacturing processes to ensure stable operation under extreme environmental conditions. Each fire pump is rigorously tested for quality and durability, ensuring rapid response and continuous water supply during emergency fire situations. With intelligent control systems, automatic switching functions, and energy-efficient designs, our products lead the industry in both performance and cost-effectiveness.

As innovators in the industry, we continuously drive market changes, optimize product features, and provide tailored solutions to meet customer needs. Understanding the critical importance of fire safety, we approach the design and manufacturing of every piece of equipment with precision and professionalism, ensuring robust support in the face of any emergency fire incident.