Diesel engine fire pump has good starting characteristics

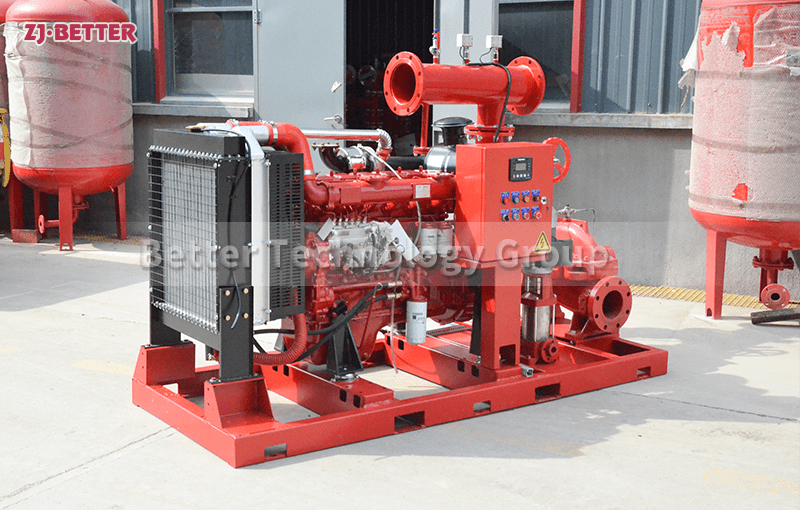

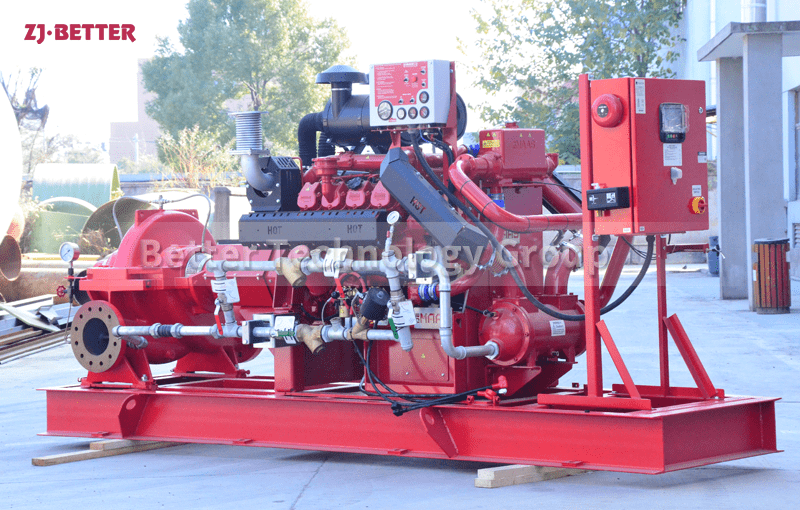

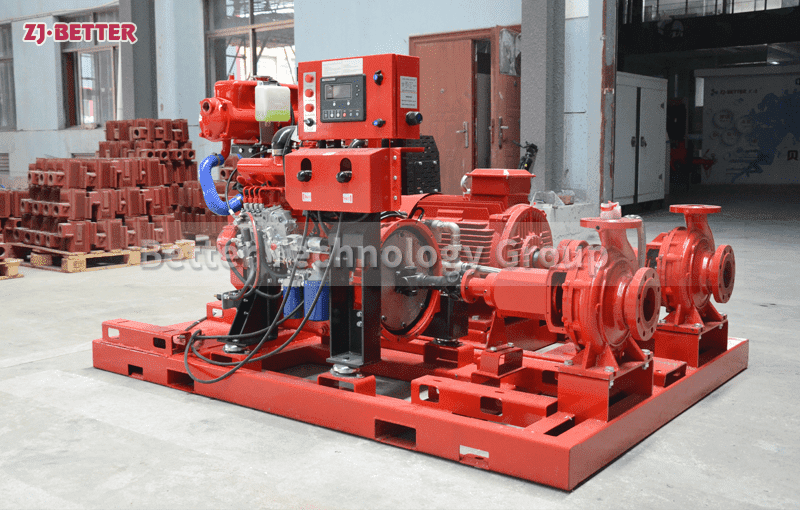

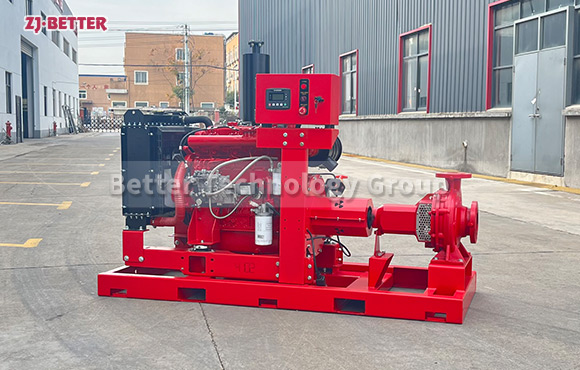

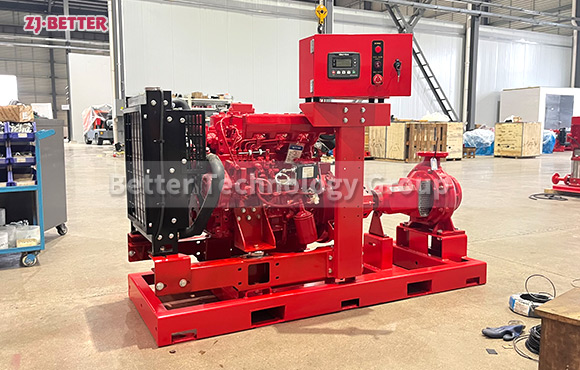

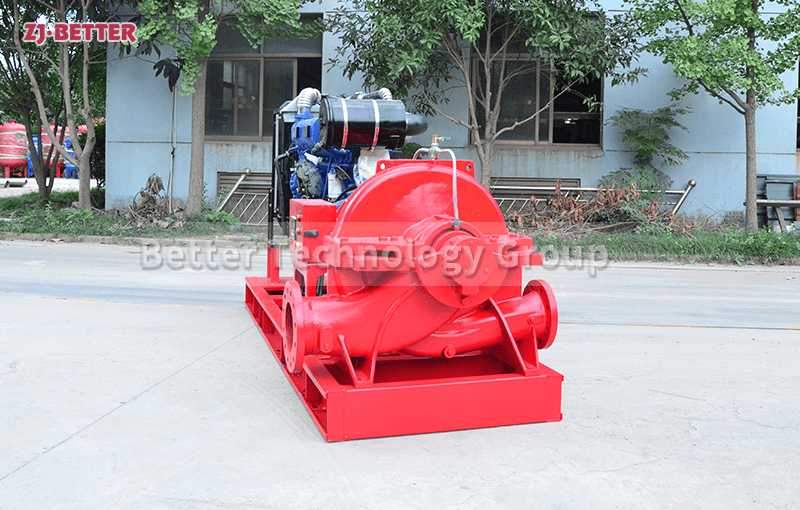

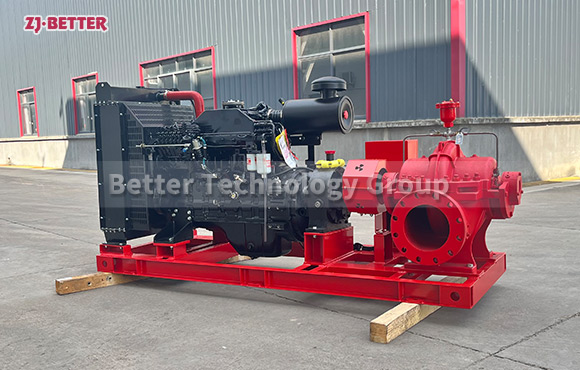

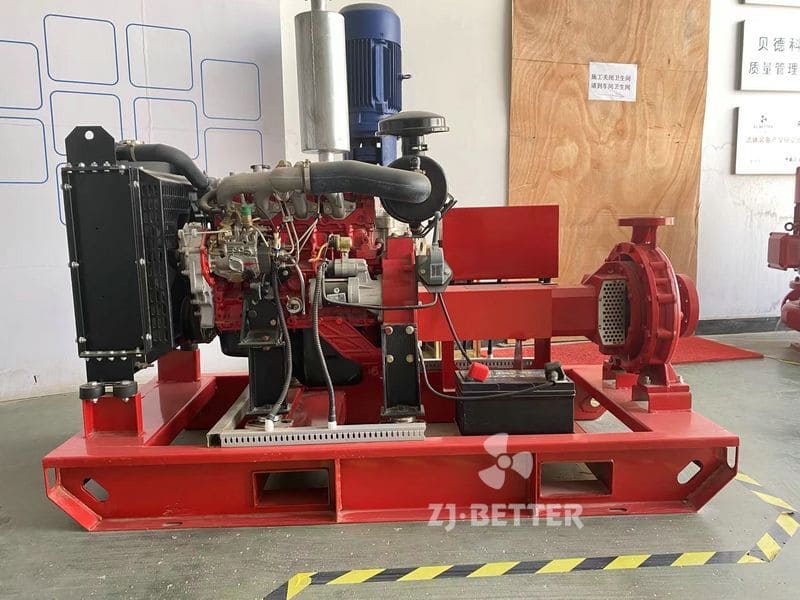

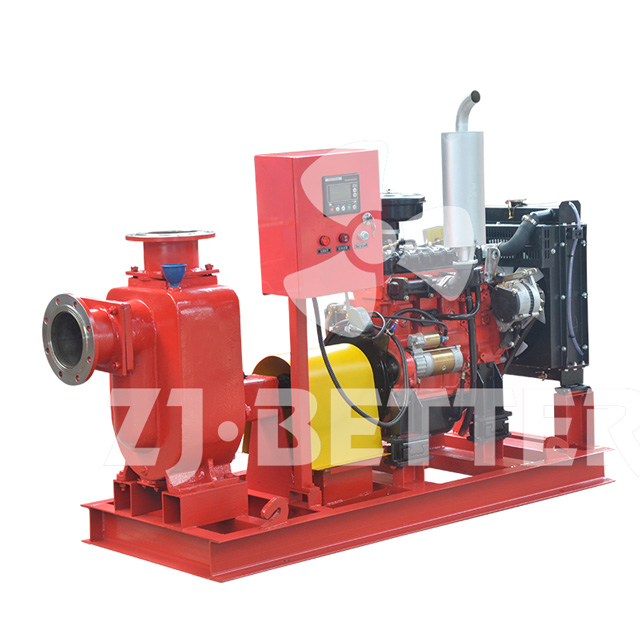

The diesel engine fire pump has the characteristics of good starting characteristics, strong overload capacity, compact and reasonable structure, convenient maintenance, simple and reliable use, etc. The unit is equipped with protection functions such as overspeed, low oil pressure, three start failures, high water temperature, low oil level, and low battery voltage. Diesel engine fire pump is composed of diesel engine, chassis, cooling water tank and fan, high elastic coupling, water pump, diesel tank and control panel and other equipment. The diesel engine fire pump is directly connected with the diesel engine through a highly elastic coupling or a diaphragm coupling, and is installed on a common channel steel chassis.

Diesel engine fire pump is simple in structure, reliable in use, convenient in installation, high in efficiency, small in size, light in weight, and has direct drive and variable speed drive. When ordering, the model (power, speed) of the power machine should be specified in order to determine the specifications of the coupling or pulley. Seen from the diesel engine pump to the water pump inlet, the impeller generally rotates counterclockwise. Diesel engine fire pumps adopt advanced air-cooled four-stroke direct-injection diesel engine as the power system, with compact structure, lighter weight and strong power. The main application of diesel engine pump: agricultural drainage and irrigation, industrial drainage and other devices. The diesel engine pump can be selected according to the specific requirements of the head, flow rate and conveying liquid of the place of use.

.jpg)