Top Choice for Industrial Sites: Efficiency and Advantages of Multistage Centrifugal Fire Pump Units

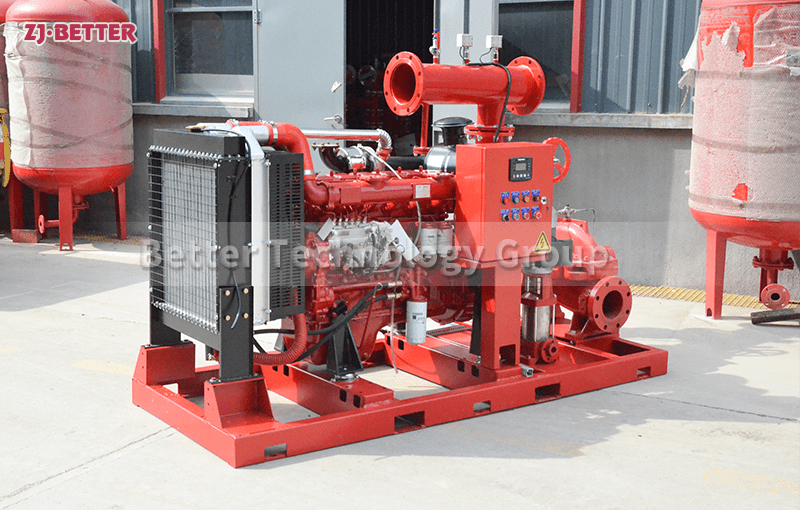

In demanding industrial environments such as chemical plants, logistics warehouses, power facilities, and manufacturing zones, fire protection systems must offer not only rapid response but also reliable and continuous water pressure. This diesel engine-driven horizontal multistage centrifugal fire pump set is purpose-built to meet such requirements.

Featuring a multistage impeller design, the unit delivers high head and large flow for efficient water supply. Its diesel engine ensures uninterrupted operation during power outages, securing critical infrastructure. The modular skid-mounted base simplifies installation, while the integrated smart control panel supports one-touch startup, automatic switching, and fault alerts—greatly enhancing system safety and intelligence.

Whether for indoor pipe networks or outdoor sprinkler systems, this fire pump unit provides consistent high-pressure output and is an essential asset for industrial fire protection.

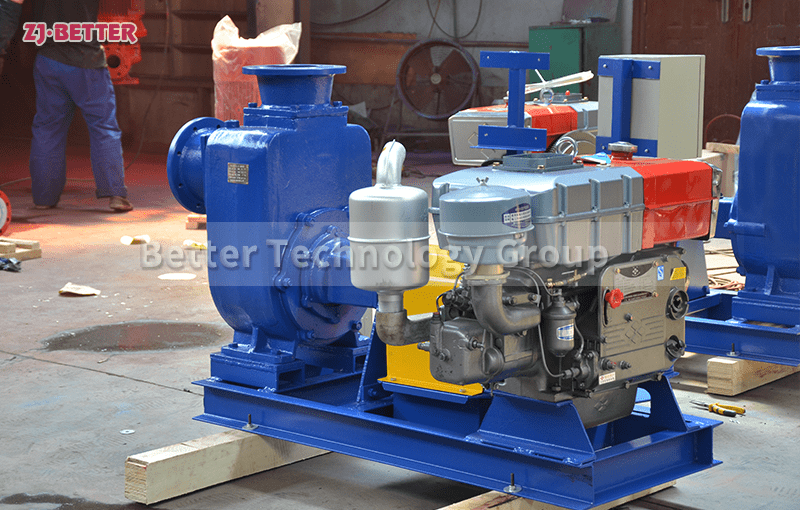

This enterprise is a high-tech manufacturer dedicated to the research, development, and production of advanced fire pump systems. With years of industry experience and strong technical expertise, it offers a comprehensive range of products including diesel engine fire pump units, electric motor fire pumps, pressure maintenance systems, fire control panels, and fully integrated automation solutions. These products are engineered to meet various international standards and cater to a wide range of fire protection applications.

Equipped with a modern manufacturing facility, the company utilizes CNC machining centers, automated painting systems, and advanced pump testing platforms. It carries out a fully integrated production process—from precision component machining to complete system assembly. Every unit undergoes rigorous testing and quality inspection before delivery, ensuring excellent performance and long service life. The company has obtained multiple quality management certifications and fire protection product approvals, reinforcing its reputation for reliability.

Its dedicated R&D center focuses on product efficiency, smart control integration, and enhanced emergency responsiveness. The engineering team continuously drives product innovation, developing multiple series that comply with global standards such as UL, NFPA, and GB. These innovations offer customers more intelligent, safe, and energy-efficient fire protection solutions.

To support its global clientele, the company has established a robust service system covering pre-sale consultation, system design, installation guidance, and after-sales support. Its products have been successfully exported to Southeast Asia, the Middle East, South America, Africa, and beyond—earning widespread recognition and trust in international markets.

Guided by the principles of quality-centered manufacturing, technology-driven growth, and customer-oriented service, the company is committed to delivering dependable fire water system solutions to partners around the world.