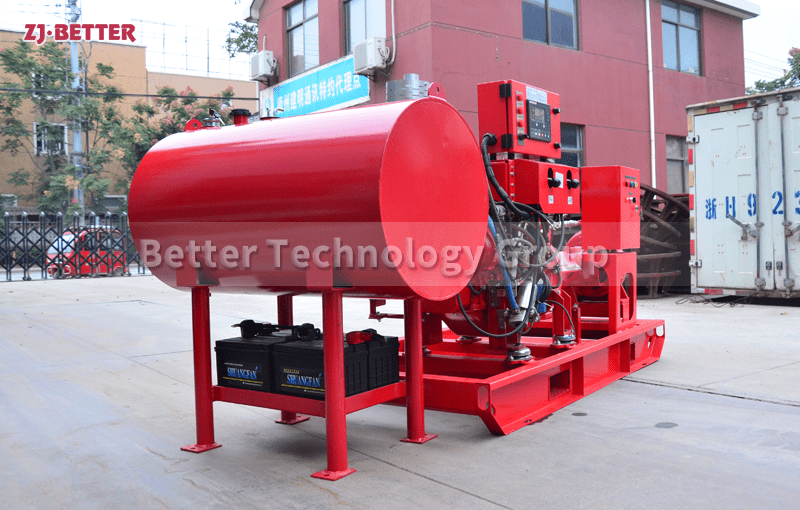

Reliable Fire Protection Made Easy with the XBC-D Diesel Engine Fire Pump

XBC-D Diesel Fire Pump Set is a versatile and reliable firefighting solution designed for a wide range of applications. Whether it’s industrial facilities, commercial buildings, residential complexes, or public infrastructure, the XBC-D Diesel Fire Pump Set ensures effective fire protection. With its robust design and advanced features, this pump set is ready to tackle emergencies and safeguard lives and properties in various firefighting scenarios.

🚒Key Features and Benefits:

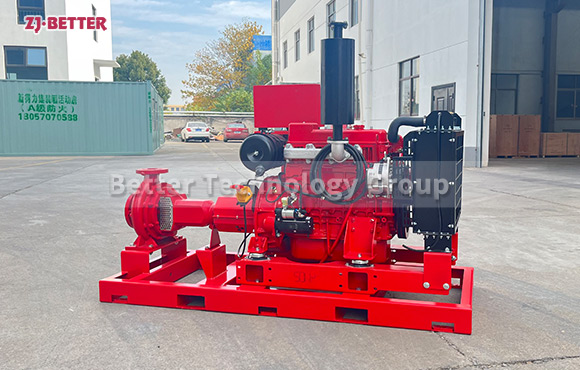

1.Robust Diesel Engine: The XBC-D Diesel Engine Fire Pump is equipped with a powerful and reliable diesel engine, delivering exceptional performance and ensuring a constant water supply for firefighting operations.

2.Enhanced Pump Efficiency: With its advanced water pump system, this pump provides optimal water pressure and flow rates, maximizing the effectiveness of fire suppression efforts.

3.Flexible Applications: Whether it’s industrial facilities, commercial buildings, residential areas, or public infrastructure, the XBC-D Diesel Engine Fire Pump is adaptable to various firefighting scenarios, making it a versatile choice for fire safety.

4.Automated Control System: Featuring an intelligent control system, this pump offers automated startup, shutdown, and monitoring functions, enabling easy operation and ensuring peace of mind during emergencies.

5.Durable and Reliable: Built with high-quality materials and precision engineering, the XBC-D Diesel Engine Fire Pump is designed to withstand demanding conditions and deliver consistent performance when it matters most.

🏢 Wide Range of Applications: The XBC-D Diesel Engine Fire Pump serves as an essential firefighting tool across different industries and sectors, including manufacturing plants, warehouses, commercial complexes, residential buildings, and more. Its versatility and reliability make it an ideal choice for protecting lives and property.