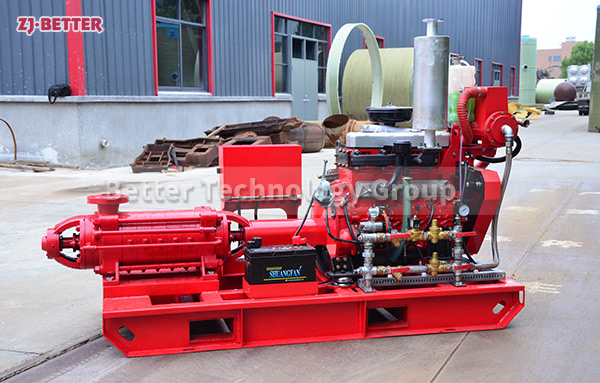

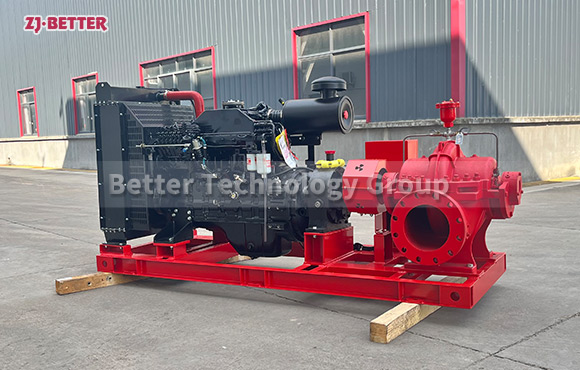

XBC-D Diesel Fire Pump Set offers you excellent firefighting solutions.

The XBC-D Diesel Engine Fire Pump is specifically designed for various firefighting locations, including factories, commercial buildings, residential areas, and public facilities. It provides a reliable source of firefighting water and increases water pressure to meet emergency water supply and firefighting needs, especially in situations without electricity supply or during power outages.

1.Robust Diesel Engine: The XBC-D Diesel Engine Fire Pump is equipped with a dependable diesel engine that ensures reliable operation even in the absence of electrical power.

2.Automated Control: The equipment incorporates an advanced automated control system for startup, shutdown, and monitoring functions, ensuring proper pump operation and safety protection.

3.High Performance: The water pump system of the XBC-D Diesel Engine Fire Pump is designed for efficiency, delivering ample water pressure and flow to meet various firefighting requirements.

4.Portability and Flexibility: The pump is typically designed as a portable or mobile device, facilitating quick deployment and emergency use.