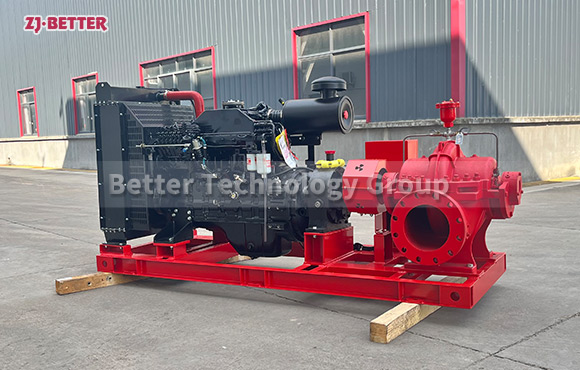

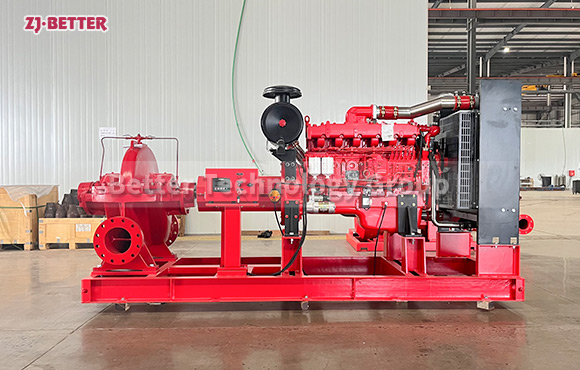

Diesel Split Case Fire Pump With Heat Exchange Engine

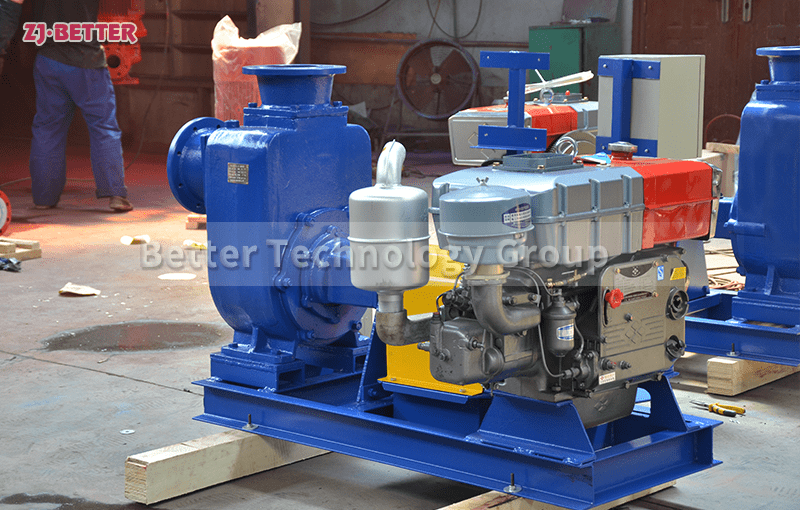

This is a our hot-selling product,it is a diesel fire pump, which is used split case pump and heat exchange engine driven.

The advantage for this pump is big flow and heat exchange engine will take low fuel consumption rate ,high thermal efficiency,small size ,flexible, and light weight,it is a good choice if you are searching for a Cost-effective diesel engine pump .

Better Technology Group Co., Ltd. was founded in 2002. We are locate in HangBu development zone, Quzhou, Zhejiang, with convenient transportation access, covering an area of 20000 square meters,for 15000 square meters workshop. It combines the functions of professional design, development, manufacture and sale of general fluid equipment of high-tech enterprise. In order to supply high quality products and good services, Better Technology founded motor factory and control panel factory. At the same time, we accept customized product order.

Better Pump has established many sales distributions and agencies in the major provinces in China. Through attending a variety of large scale exhibition, we have developed a broader market.

We are looking forward to forming successful business relationships with new clients around the world in the near future.