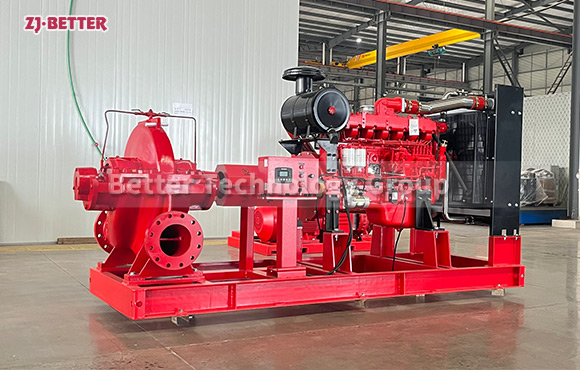

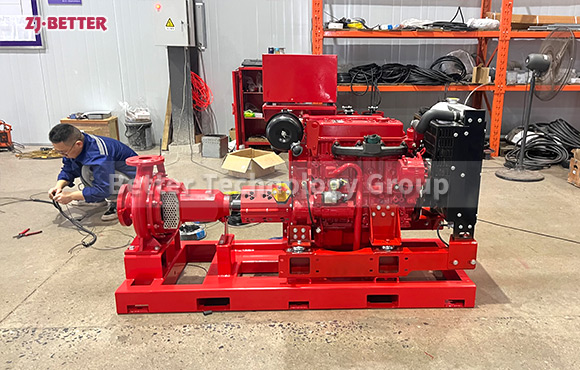

Diesel fire pump is a reliable fire fighting equipment

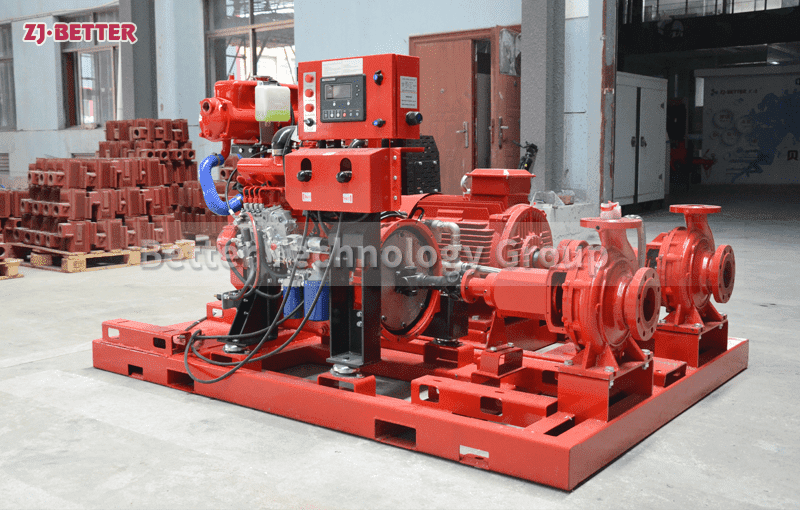

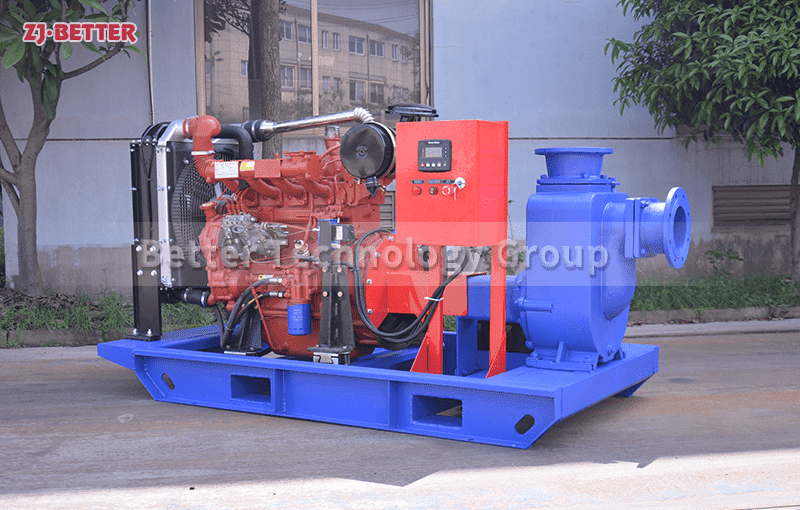

The national standard name of the diesel engine fire pump is “engineering diesel engine fire pump set”, and the national standard model is XBCL/Q, where L is the lift value and Q is the flow value. The XBC diesel engine fire pump set is newly issued according to the national standard GB6245-2006 “Fire Pump Performance Requirements and Test Methods”. This series of products has a wide range of head and flow, which can meet the fire water supply in various occasions of industrial and mining enterprises such as warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, and textiles.

The diesel fire pump has the characteristics of good startability, strong overload capacity, compact structure, convenient maintenance, simple use, and high degree of automation. It is a reliable fire-fighting equipment.

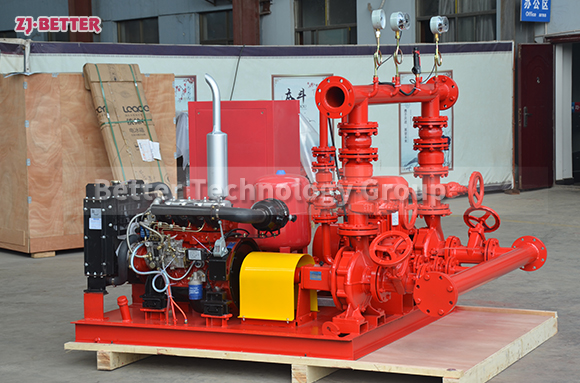

1. Manual start function: through the transfer switch, manual and dynamic interlocking and manual start function can be realized;

2. Automatic start function: three starts are allowed, and if the three starts are unsuccessful, a “start failure alarm” will be issued and the start state will be automatically exited; after one start is successful, the time to start to rated load is 5-10-15S (varies according to the capacity of the unit) )

3. Emergency manual direct start function: when the automatic control device fails, the emergency manual direct start function can be realized.

Automatic operation: When the water pump unit receives an effective fire signal, if the power supply system of the motor fire pump is out of power or lacks a phase or the electric pump fails to start normally, the diesel engine fire pump unit will automatically start and run. Once the power supply system returns to normal or the electric pump When it can run normally, it can automatically switch to the electric pump.

Active shutdown: when the fire signal disappears, the fire pump will automatically delay shutdown.